Understanding Molecular Dynamics Simulations in Nanotechnology

Definition: Molecular Dynamics (MD) Simulations are a computer simulation technique used to study the physical movements of atoms and molecules. By simulating the interactions and dynamics of particles, MD provides deep insights into the material properties, reaction processes, and mechanism of action at the atomic scale, making it crucial for research and development in nanotechnology and materials science.

Principles Behind Molecular Dynamics Simulations

Molecular Dynamics Simulations are grounded in classical mechanics, particularly Newton’s laws of motion, to predict how particles move within a system. The force acting on each atom is calculated based on the potential energy derived from molecular interaction potentials. By integrating these forces over time, MD simulations can recreate the trajectories of atoms and molecules, revealing dynamic properties and behaviors.

How Molecular Dynamics Simulations Work

Molecular Dynamics (MD) Simulations follow a step-by-step process to replicate the physical behaviors of atoms and molecules within a virtual environment. This detailed guide breaks down the essential stages and principles involved:

Initial Setup

- Selection of the Molecular System: The first step involves defining the atomic or molecular system to be studied. This could range from a simple collection of water molecules to complex biological macromolecules like proteins.

- Definition of the Simulation Box: The molecular system is placed within a virtual box, defining the boundaries of the simulation. Periodic boundary conditions are often applied to mimic an infinite system and minimize edge effects.

- Assignment of Initial Conditions: Initial velocities and positions are assigned to the atoms based on their expected equilibrium distributions at the simulation temperature. This step is crucial for starting the dynamic evolution of the system.

Force Field Application

- Interatomic Potentials: A force field, a mathematical model describing the forces acting between atoms, is applied. It includes terms for bond stretching, angle bending, van der Waals forces, and electrostatic interactions. The choice of force field affects the accuracy and reliability of the simulation outcomes.

Integration of Equations of Motion

- Time Evolution: The core of MD simulation lies in solving Newton's equations of motion for the particles in the system. By numerically integrating these equations, the simulator calculates the trajectories of atoms over time, accounting for the forces and potential energies at each timestep.

- Temporal Resolution: Simulations are conducted over discrete time steps, typically in the femtosecond range (10-15 seconds), to ensure accuracy in tracking the atomic motions.

Thermostats and Barostats

- Temperature and Pressure Control: To simulate the conditions of real-world environments, MD simulations use thermostats and barostats to regulate the temperature and pressure of the system, respectively. This control is vital for studying phenomena under specific thermal and mechanical conditions.

Data Collection and Analysis

- Observables and Properties: Throughout the simulation, various physical properties such as temperature, pressure, energy, and structural data are calculated. These observables provide insights into the material's behavior and properties at the molecular level.

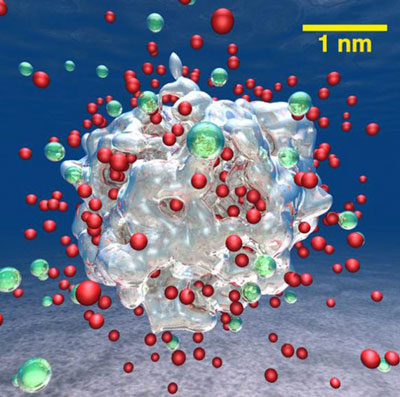

- Visualization: Advanced visualization tools are used to interpret the trajectories and dynamics of the particles, offering an intuitive understanding of the molecular interactions and processes.

Challenges and Computational Considerations

- Computational Demand: MD simulations are computationally intensive, requiring significant computational resources, especially as the size of the system or the simulation time increases.

- Scale Limitations: While powerful, MD simulations are primarily constrained to studying phenomena at the nanoscale over relatively short physical timescales. Bridging these simulations to larger scales or longer times requires sophisticated modeling and computational techniques.

By following these steps, Molecular Dynamics Simulations provide a dynamic window into the microscopic world, allowing scientists and engineers to decode the complexities of materials and biological systems at an unprecedented level of detail.

Applications in Nanotechnology and Materials Science

Molecular Dynamics Simulations have wide-ranging applications in nanotechnology and materials science. They are instrumental in:

- Material Design and Characterization: MD simulations help in understanding the material behavior at the atomic level, aiding in the design of new materials with desired properties.

- Understanding Biological Processes: They are used to simulate the dynamics of biological molecules like proteins and DNA, helping in drug design and the understanding of diseases at the molecular level.

- Enhancing Performance of Nanodevices: By simulating the physical properties of materials, MD can predict the performance of nanodevices and optimize their design for specific applications.

- Studying Thermal Conductivity and Mechanical Properties: MD simulations are key in investigating the thermal and mechanical properties of materials, which are critical for developing more efficient and durable products.

Challenges and Limitations

While powerful, Molecular Dynamics Simulations have their set of challenges:

- Computational Resources: MD simulations are computationally intensive, requiring significant computational power, especially for large systems or long simulation times.

- Accuracy of Models: The reliability of MD simulations depends on the accuracy of the interatomic potential models used to calculate forces between atoms. Developing precise models is complex and can limit the simulation's accuracy.

- Time and Length Scale Limitations: Traditional MD simulations are limited to relatively short time scales and small system sizes, which may not always capture long-term processes or bulk material properties.

Technological Advancements and Future Directions

Recent advancements in computational power, algorithm development, and the creation of more accurate potential models have significantly improved the scope and accuracy of MD simulations. Techniques such as parallel computing and enhanced sampling methods are pushing the boundaries, allowing simulations of larger systems over longer timescales. Furthermore, integrating MD with quantum mechanical methods and machine learning algorithms is opening new avenues for research, enabling more precise simulations and predictions of material behavior under diverse conditions.

Innovations in MD simulations continue to expand their applications in nanotechnology, materials science, biology, and beyond, providing valuable insights that drive scientific discovery and technological progress.

Further Reading

Journal of Materials Science and Chemical Engineering, Molecular Dynamics (MD) Applications in Materials Science and Engineering and Nanotechnology