Spin Valve: A Key Component in Spintronics and Data Storage

What is a Spin Valve?

A spin valve is a device that exploits the spin-dependent electron transport properties of ferromagnetic materials to control the flow of electrons. It consists of two ferromagnetic layers separated by a thin non-magnetic spacer layer. The resistance of the device depends on the relative orientation of the magnetization in the two ferromagnetic layers, which can be controlled by an external magnetic field. This change in resistance, known as giant magnetoresistance (GMR), forms the basis for various applications in spintronics and data storage.

Key Concepts in Spin Valves

The operation of a spin valve relies on several key concepts in spintronics:

- Spin-Dependent Transport: In ferromagnetic materials, the electrical conductivity depends on the spin orientation of the electrons. Electrons with spins aligned parallel to the magnetization of the material experience less scattering and have a higher conductivity compared to electrons with antiparallel spins.

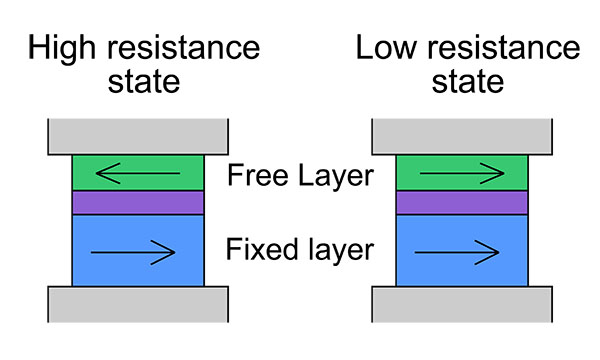

- Giant Magnetoresistance (GMR): GMR is the large change in resistance observed in a spin valve when the relative orientation of the magnetization in the ferromagnetic layers is switched between parallel and antiparallel states. The resistance is low when the magnetizations are parallel and high when they are antiparallel.

- Magnetic Anisotropy: Magnetic anisotropy refers to the preference for the magnetization to align along a particular direction, known as the easy axis. In spin valves, one ferromagnetic layer (the pinned layer) has its magnetization fixed by coupling to an antiferromagnetic layer, while the other ferromagnetic layer (the free layer) can switch its magnetization in response to an external magnetic field.

Structure and Operation of Spin Valves

A typical spin valve consists of the following layers:

- Pinned Layer: A ferromagnetic layer with a fixed magnetization direction, usually achieved by coupling to an adjacent antiferromagnetic layer.

- Spacer Layer: A thin non-magnetic layer, typically made of copper, that separates the pinned and free layers. The thickness of the spacer layer is critical for achieving the desired GMR effect.

- Free Layer: A ferromagnetic layer whose magnetization can be switched by an external magnetic field. The orientation of the free layer's magnetization relative to the pinned layer determines the resistance of the spin valve.

The operation of a spin valve can be understood as follows:

- When the magnetizations of the pinned and free layers are parallel, electrons with spins aligned to the magnetization can pass through both layers easily, resulting in a low resistance state.

- When the magnetizations of the pinned and free layers are antiparallel, electrons with spins aligned to the magnetization of one layer will be scattered in the other layer, leading to a high resistance state.

- By applying an external magnetic field, the magnetization of the free layer can be switched between parallel and antiparallel states, thereby changing the resistance of the spin valve.

Applications of Spin Valves

Spin valves have found numerous applications in spintronics and data storage devices:

Magnetic Field Sensors

Spin valves are highly sensitive to external magnetic fields, making them ideal for use as magnetic field sensors. They are employed in a wide range of applications, such as automotive sensors, electronic compasses, and biosensors.

Magnetic Random Access Memory (MRAM)

Spin valves form the basic building blocks of MRAM, a non-volatile memory technology that stores data using the magnetization state of the device. MRAM offers high speed, low power consumption, and unlimited endurance, making it a promising alternative to conventional memory technologies.

Hard Disk Drive (HDD) Read Heads

Spin valves have revolutionized the data storage industry by enabling the development of high-sensitivity read heads for HDDs. The GMR effect allows for the detection of smaller magnetic bits, leading to increased storage density and capacity in modern HDDs.

Challenges and Future Perspectives

Despite the success of spin valves in various applications, there are still challenges to be addressed. One of the main challenges is the scalability of spin valves to smaller dimensions while maintaining their performance. As the size of the devices decreases, issues such as magnetic instability, current-induced magnetization switching, and thermal fluctuations become more pronounced.

Future research in spin valves will focus on developing novel materials and device architectures to overcome these challenges. The use of perpendicular magnetic anisotropy materials, such as CoFeB/MgO, has shown promise in enhancing the stability and performance of spin valves at reduced dimensions. Additionally, the integration of spin valves with other emerging technologies, such as spin-orbit torque and spin-transfer torque, will enable the development of more efficient and versatile spintronic devices.

Further Reading

Journal of Physics D: Applied Physics, A brief review on the spin valve magnetic tunnel junction composed of 2D materials

Semiconductors, Spin Valves in Microelectronics (A Review)

Advanced Functional Materials, Organic Spin Valves: A Review