| Posted: Jun 20, 2018 |

The synthetic techniques and applications of quantum dot - graphene composites

(Nanowerk News) Recent research published in a paper in NANO by a group of researchers from Yunnan University investigates the recent research progress on quantum dots/graphene (QDs/GR) composites with focus on their industrial preparation and commercial applications. The selection of the appropriate synthetic method is highly dependent on the applying requirements of QDs/GR composites.

|

|

A team of researchers from the Yunnan University in China have published a review article investigating recent research progress on QDs/GR composites, particularly, for their industrial preparation and commercial applications. Ion beam sputtering deposition (IBSD) and molecular beam epitaxy (MBE) were discussed in detail. Their article appears in the forthcoming issue of the journal NANO ("Review of the Synthetic Techniques and Applications of the Quantum Dots/Graphene Composites").

|

|

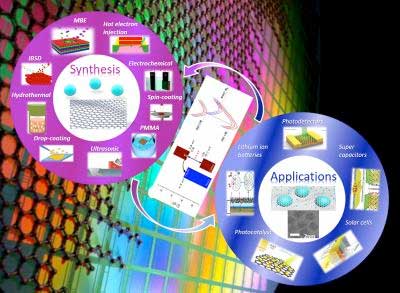

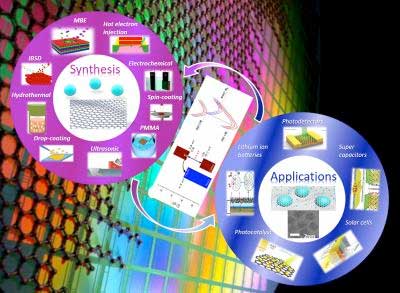

| Schematic illustration for the preparation methods and applications of quantum dots/graphene (QDs/GR) composite materials. (Image: Tao Sun)

|

|

The QDs/GR composite is a relatively new interdisciplinary field which has attracted numerous interest. Due to single QDs and graphene materials having their inherent defects, their applications are significantly limited. For example, the low carrier mobility of QDs limits the optical gain of QDs, the light absorbance of graphene materials is weak and graphene materials always aggregate and hardly disperse during synthetic processes. The shortcomings of the single QD and graphene materials can be remedied by the synergistic effects from QDs/GR composite materials.

|

|

The QDs/GR composite is a relatively new interdisciplinary field which provided a path for overcoming the shortages of single QDs or graphene materials, and attracted lots of interest. The synergistic effects of the QDs/GR composite materials highly promotes their superior advantages and applications. In this hybrid structure, QDs are often used as light-absorbing materials, where electron hole pairs are produced under the irradiation of light.

|

|

Graphene is an excellent charge transfer material, and decorated QDs on graphene sheets can effectively improve the visible light absorption, charge separation and carrier mobility. In addition, its volume expansion/constriction can be buffered by the reticular structure of graphene during cyclic processes, and the excellent conductivity of graphene also contributes to this hybrid being applied in quick-acting charging.

|

|

The QDs/GR composites processed better photocatalytic activities, higher photon capture abilities and excellent optical responsibilities. Meanwhile, some unique phenomena and superior physical properties were also produced. The advanced physical and chemical properties promoting this composite have numerous potential for being applied in photodetectors, lithium ion batteries, solar cells, supercapacitors and other devices.

|

|

There are many ways to synthesize QDs/GR composites materials, like IBSD, MBE, hydrothermal, solvothermal, drop-casting, spin-coating, ultrasonic, PMMA and electrochemical methods. The selection of preparation method for QDs/GR composites is highly dependent on their applications, with the synthetic procedure prominently affecting the capability and performance of these composites. Compared to other methods, the hydro/solvo-thermal methods produced uncontrollable size QDs even with its uniform hybrid dispersed, which are inappropriate for synthesis QDs/GR composites for application to photoelectric devices.

|

|

At present, the dropping-casting and spin-coating methods are the common approaches to easily control the thickness of QDs film, but the reaction solvent brings significant impact and affects the quality of the produced film. Recently, the ultrasonic and PMMA aid-transfer methods have attracted scientific interests.

|

|

In the hybrid processed, the ultrasonic methods could supply extra driving force, but the degree of driving forces is hard to control. In addition, in the transfer processes of the PMMA aid-transfer method, the graphene quality might be destroyed to a certain extent. An atomic layer deposition technique might accurately control the membrane thickness by adjusting the cycling numbers and produce the ideal QDs/GR composites.

|

|

Among these synthetic methods, IBSD and MBE were discussed in detail because they could be directly applied in the commercial industry for preparing size-tunable quantum dots. However, for the ISBD and MBE technique, the short lifetime of the vacuum pump still limits its industrialized production. Comparing the well-crystalline and high density QDs produced by expensive MBE method and the ordered and size-tunable QDs/GR composites produced via low-costing IBSD are rarely investigated, although these physical methods have huge potential for QDs/GR composites large scale preparation.

|

|

The Yunnan University team is currently exploring options to find a convenient, environmentally friendly and low-cost synthesis method for QDs/GR composites to bring out their outstanding chemical and physical properties.

|