| Dec 11, 2018 | |

Cutting and pasting with graphene(Nanowerk News) To date it has proved very difficult to convert the promises of graphene into practical applications. |

|

| Amedeo Bellunato, PhD candidate at the Leiden Institute of Chemistry, has developed a method of cutting graphene into smaller fragments using a diamond knife. He can then construct nanostructures from the fragments. PhD defence on 11 December. | |

| Graphene is a honeycomb structure of carbon atoms just a single atom thick. After its discovery in 2004, it seemed to be the ideal basic material for nanotechnology applications: it is super strong and it is an exceptionally good conductor of both heat and electricity. | |

| In 2013 the EU launched the Graphene Flagship a research programme with a budget of a billion euros to develop such applications as more efficient solar cells, LEDs, batteries and all kinds of sensors. | |

| However, in his dissertation, Bellunato states that making such nanostructures is still an extremely complex production process that does not lend itself well toserial production. | |

| Also, it has proven almost impossibleto selectively 'functionalize' graphene chemically, i.e. to connect other chemical elements, such as oxygen or nitrogen atoms, to the edges of a graphene nanostructure. | |

| It is important to be able to do this in order to make graphene into a versatile nanomaterial with multiple applications. | |

|

|

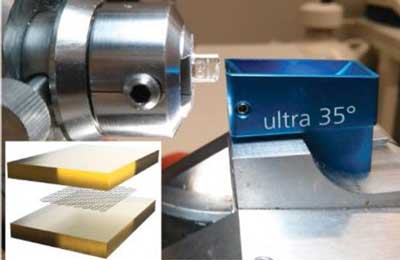

| The microtome that cuts exceptionally precise strips of of graphene. The sandwich with the graphene (inset) is the transparent block to the left, the diamond knife can be seen at the edge of the blue container. | |

| Inspired by earlier experiments, Bellunato decided to take a different approach, namely to take a sandwich of plastic and metal with a layer of graphene in the middle, and to literally cut it into fragments. He does this using a microtome, a diamond knife that can cut fragments with nanometre precision. | |

| In the cutting edge of the sandwich, a perfectly clean, one-atom-thick edge of graphene is exposed, to which other atoms or molecules can be connected by chemical means. The graphene slicecan also be connected to an electrical current, turning it into an electrochemical cell. This can be compared with the electrochemical coating of a metal, but then at nanoscale, since only the edge of the graphene is coated. | |

| Bellunato was also able to build a sandwich of nanopores and nanogapsof graphene using microscopically thin strips. | |

| It also proved possible to make a so-called tunnel junction. This occurs between two electrical conductors, when they are within a few nanometres of one another at a particular point. A minuscule current can then flow between the two conductors. As the flow of energy is very sensitive to the distance between the conductors, this tunnel effect forms the basis for all kinds of extremely sensitive sensors. | |

| Bellunato: 'This tunnel junction is not new. It is a matter of refining the technique, and then it should have practical applications within five years or so.' The unconventional technique that he developed will not primarily be used in consumer products, he expects, but rather in advanced research instruments. |

| Source: UCLA | |

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |