| Mar 06, 2019 | |

Nanoparticle performance - solving a sticky problem(Nanowerk News) Although far thinner than a human hair, metal nanoparticles play an important role in advanced industries and technologies from electronics and pharmaceuticals to catalysts and sensors. Nanoparticles can be as small as ten atoms in diameter, and their small size makes them especially susceptible to coarsening with continued use, which reduces functionality and degrades performance. |

|

| To advance the understanding of micro- and nano-surfaces and to engineer more stable nanoparticles, the National Science Foundation has awarded the University of Pittsburgh’s Tevis Jacobs a $500,000 CAREER Award ("Understanding Nanoparticle Adhesion to Guide the Surface Engineering of Supporting Structures"), which supports early-career faculty who have the potential to serve as academic role models in research and education and to lead advances in the mission of their department or organization. | |

|

|

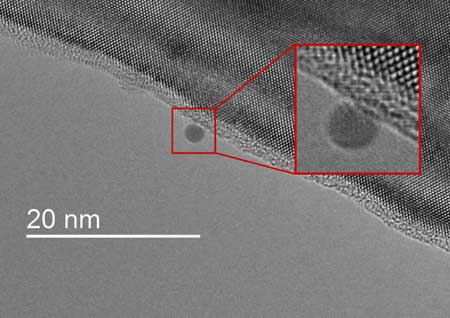

| Electron microscopy is used to observe and test individual nanoparticles on flat surfaces. The adhesion of these nanoparticles can be correlated to the their size, shape, and materials structure. (Image: Tevis Jacobs) | |

| Dr. Jacobs, assistant professor of mechanical engineering and materials science at Pitt’s Swanson School of Engineering, will utilize electron microscopy to directly study and measure adhesion properties of nanoparticles and their supporting substrates. | |

| “Research has already shown that nanoparticle coarsening is related to nanoparticle adhesion; however, those prior studies measured the aggregate behavior of billions of particles simultaneously. The large number of particles prevented systematic investigation of the key factors governing adhesion. To gain a better understanding, we need to be able to study individual nanoparticles in action, in real time,” Dr. Jacobs explains. “Our suite of tools for performing mechanical and materials testing inside of a transmission electron microscope allows for direct measurements of adhesion under different circumstances. These measurements will enable greater understanding of the atomic-scale relationships between nanoparticle adhesion and coarsening.” | |

| Dr. Jacobs noted that current processes to counter nanoparticle coarsening utilize stabilizing materials, but matching the most effective stabilizer to a nanoparticle is a time-consuming and costly trial-and-error process. The CAREER award will enable Dr. Jacobs and his lab group to develop new methods to measure the attachment and stability of nanoparticles on surfaces under various conditions, allowing researchers to enhance both surfaces and nanoparticles in tandem to work more effectively together. | |

| Additionally, the CAREER award allows Dr. Jacobs and his Surfaces and Small-Scale Structures Laboratory to engage with the University of Pittsburgh School of Education and a local elementary school to create and nationally disseminate surface engineering-focused curricular units for sixth- to eighth-grade students and professional development training modules for teachers. | |

| “Incorporating engineering projects in early grades has the potential to inspire more students of all backgrounds to become interested in STEM, and can have particularly strong effects on groups that are underrepresented in STEM careers today,” Dr. Jacobs said. “And on the research side, the improvements in nanoparticle performance will have direct benefit in applications such as manufacturing, solar energy, and sensors for the detection of pollutants in the environment and diseases in the body.” |

| Source: University of Pittsburgh | |

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |