| Mar 18, 2020 | |

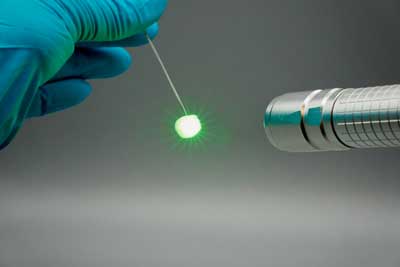

'White graphene' aerogel material creates pleasant laser light(Nanowerk News) With a porosity of 99.99 %, it consists practically only of air, making it one of the lightest materials in the world: Aerobornitride is the name of the material developed by an international research team led by Kiel University. The scientists assume that they have thereby created a central basis for bringing laser light into a broad application range. |

|

| Based on a boron-nitrogen compound, they developed a special three-dimensional nanostructure that scatters light very strongly and hardly absorbs it. Irradiated with a laser, the material emits uniform lighting, which, depending on the type of laser, is much more efficient and powerful than LED light. Thus, lamps for car headlights, projectors or room lighting with laser light could become smaller and brighter in the future. | |

|

|

| Aerobornitride scatters the light of a laser beam homogeneously in all directions. (Image: Florian Rasch) | |

The research team presents their results in Nature Communications ("Conversionless efficient and broadband laser light diffusers for high brightness illumination applications").

More light in the smallest space |

|

| In research and industry, laser light has long been considered the “next generation” of light sources that could even exceed the efficiency of LEDs (light-emitting diode). | |

| “For very bright or a lot of light, you need a large number of LEDs and thus space. But the same amount of light could also be obtained with a single laser diode that is one-thousandth smaller,” Dr. Fabian Schütt emphasizes the potential. | |

| The materials scientist from the working group "Functional Nanomaterials" at Kiel University is the first author of the study, which involves other researchers from Germany, England, Italy, Denmark and South Korea. | |

| Powerful small light sources allow numerous applications. The first test applications, such as in car headlights, are already available, but laser lamps have not yet become widely accepted. On the one hand, this is due to the intense, directed light of the laser diodes. On the other hand, the light consists of only one wavelength, so it is monochromatic. This leads to an unpleasant flickering when a laser beam hits a surface and is reflected there. | |

Porous structure scatters the light extremely strongly |

|

| “Previous developments to laser light normally work with phosphors. However, they produce a relatively cold light, are not stable in the long term and are not very efficient,” says Professor Rainer Adelung, head of the working group. | |

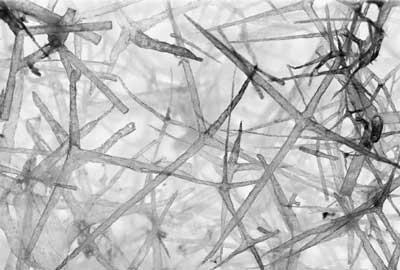

| The research team in Kiel is taking a different approach: They developed a highly scattering nanostructure of hexagonal boron nitride, also known as "white graphene", which absorbs almost no light. The structure consists of a filigree network of countless fine hollow microtubes. When a laser beam hits these, it is extremely scattered inside the network structure, creating a homogeneous light source. | |

| "Our material acts more or less like an artificial fog that produces a uniform, pleasant light output," explains Schütt. The strong scattering also contributes to the fact that the disturbing flickering is no longer visible to the human eye. | |

|

|

| Within the fine network of hollow tubes measuring only a few micrometers in size incident laser beams are so strongly scattered that a homogeneous white light is produced. (Image: Fabian Schütt) | |

| The nanostructure not only ensures that the material withstands the intense laser light, but can also scatter different wavelengths. Red, green and blue laser light can be mixed in order to create specific color effects in addition to normal white - for example, for use in innovative room lighting. Here, extremely lightweight laser diodes could lead to completely new design concepts in the future. | |

| "However, in order to compete with LEDs in the future, the efficiency of laser diodes must be improved as well," says Schütt. The research team is now looking for industrial partners to take the step from the laboratory to application. | |

Wide range of applications for aeromaterials |

|

| Meanwhile the researchers from Kiel can use their method to develop highly porous nanostructures for different materials, besides boron nitride also graphene or graphite. In this way, more and more new, lightweight materials, so-called “aeromaterials”, are created, which allow particularly innovative applications. For example, the scientists are currently doing research in collaboration with companies and other universities to develop self-cleaning air filters for aircraft. |

| Source: Christian-Albrechts-Universität zu Kiel | |

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |