| Jun 25, 2020 | |

Trapping the sun: New thin-film technology uses sustainable components for solar panels(Nanowerk News) Commercialized thin-film solar panels on the market consist of rare-earth elements like indium and gallium, or highly toxic metals like cadmium. Both of these thin-film solar panel types have their own problems, such as high-cost and problems in use in living places. |

|

| A team of scientists from DGIST, led by Dr Jin-Kyu Kang and Dr Dae-Hwan Kim, has been experimenting with solar panels made from cheaper and more abundant elements. Now, they have published the findings of their latest study in Advanced Energy Materials ("Effect of Cu-Sn-Se Liquid Phase on Grain Growth and Efficiency of CZTSSe Solar Cells"). | |

|

|

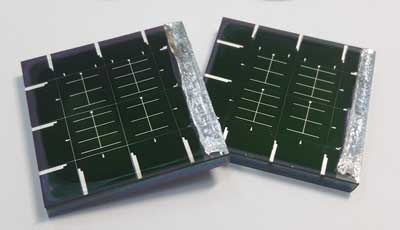

| In close proximity to our homes and lives, solar panels are the most efficient when they are inexpensive and non-toxic. The DGIST team prepared lab-scale CZTSSe solar cells, and one of them showed a tie world record of 12.6% conversion efficiency. (Image: DGIST) | |

| Dr Kang elaborates on the reasons based on which they chose their materials for the study: “Thin-film solar cells using bronze (Cu-Sn) and brass (Cu-Zn) as base materials are composed of non-toxic earth-abundant materials, and have been studied worldwide because of their low cost, high durability, and sustainability.” | |

| However, using these alloys in thin film technology has its own drawbacks. While the theoretical efficiency of these panels matches the efficiencies of top market products, in practice, they tend to underperform drastically. This is because of the formation of various defects in the materials, such as “point” defect, “surface” defect, and “volume” defect, during “annealing” (or the process of heating and cooling to make a CZTSSe film). These defects undermine the current flow, resulting in loss of electricity generated. | |

| Therefore, the scientists wanted to find a way to synthesize the best quality CZTSSe (copper, zinc, tin, sulfur, and selenium) thin films. They played around with the annealing profile, which has a strong effect on the grain size of CZTSSe thin film: the longer the annealing time and higher annealing temperature, the larger the grains, and the lesser the electricity loss. | |

| However, as the annealing temperature and time increase, there is a change in the properties of the CZTSSe thin film due to decomposition. To bypass this issue, the team used a special “liquid-assisted method,” which allowed the grains of CZTSSe to grow at a faster rate. This meant that the grains could grow large even at low temperatures, preventing the change in the properties of the CZTSSe thin film. | |

| With this new observation, a significant hurdle has been overcome in the search for low-cost environment-friendly solar energy. Dr Kim concludes, “Our technology has diverse applications, including in electronic devices, household goods, buildings, and vehicles. The best part is that CZTS solar cells are free of the current drawbacks of toxic and rare metals. We can install everywhere we want!” |

| Source: DGIST | |

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |