| Sep 17, 2020 | |

What happens between the sheets (of graphene)?(Nanowerk News) Adding calcium to graphene creates an extremely-promising superconductor, but where does the calcium go? |

|

| Adding calcium to a composite graphene-substrate structure creates a high transition-temperature (Tc) superconductor. | |

| In a new study (Chemistry of Materials, "Freestanding n-Doped Graphene via Intercalation of Calcium and Magnesium into the Buffer Layer-SiC(0001) Interface"), an Australian-led team has for the first time confirmed what actually happens to those calcium atoms: surprising everyone, the calcium goes underneath both the upper graphene sheet and a lower ‘buffer’ sheet, ‘floating’ the graphene on a bed of calcium atoms. | |

| Superconducting calcium-injected graphene holds great promise for energy-efficient electronics and transparent electronics. | |

|

|

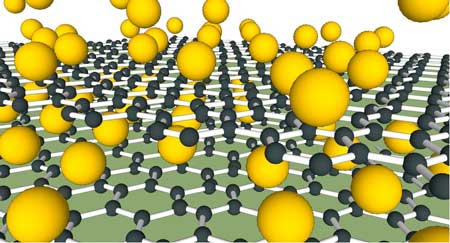

| Injecting calcium into graphene creates a superconductor, but where does the calcium actually end up? (Image: FLEET) | |

Studying calcium-doped graphene: Throwing off the duvet |

|

| Graphene’s properties can be fine-tuned by injection of another material (a process known as ‘intercalation’) either underneath the graphene, or between two graphene sheets. | |

| This injection of foreign atoms or molecules alters the electronic properties of the graphene by either increasing its conductance, decreasing interactions with the substrate, or both. | |

| Injecting calcium into graphite creates a composite material (calcium-intercalated graphite, CaC6) with a relatively ‘high’ superconducting transition temperature. In this case, the calcium atoms ultimately reside between graphene sheets. | |

| Injecting calcium into graphene on a silicon-carbide substrate also creates a high-Tc superconductor, and we always thought we knew where the calcium went in this case too... | |

| Graphene on silicon-carbide has two layers of carbon atoms: one graphene layer on top of another ‘buffer layer’: a carbon layer (graphene-like in structure) that forms between the graphene and the silicon-carbide substrate during synthesis, and is non-conducting due to being partially bonded to the substrate surface. | |

| “Imagine the silicon carbide is like a mattress with a fitted sheet (the buffer layer bonded to it) and a flat sheet (the graphene),” explains lead author Jimmy Kotsakidis. | |

| Conventional wisdom held that calcium should inject between the two carbon layers (between two sheets), similar to injection between the graphene layers in graphite. Surprisingly, the Monash University-led team found that when injected, the calcium atoms’ final destination location instead lies between buffer layer and the underlying silicon-carbide substrate (between the fitted sheet and the mattress!). | |

| “It was quite a surprise to us when we realised that the calcium was bonding to the silicon surface of the substrate, it really went against what we thought would happen”, explains Kotsakidis. | |

| Upon injection, the calcium breaks the bonds between the buffer layer and substrate surface, thus, causing the buffer layer to ‘float’ above the substrate, creating a new, quasi-freestanding bilayer graphene structure (Ca-QFSBLG). | |

| This result was unanticipated, with extensive previous studies not considering calcium intercalation underneath the buffer layer. The study thus resolves long-standing confusion and controversy regarding the position of the intercalated calcium. | |

|

|

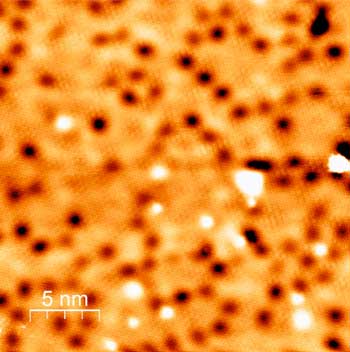

| Measurements by STM (shown), XPS and LEED pinpointed the location of the calcium near the SiC surface. (Image: FLEET) | |

| X-ray photoelectron spectroscopy (XPS) measurements at the Australian Synchrotron were able to pinpoint the location of the calcium near to the silicon carbide surface | |

| Results were also supported by low-energy electron diffraction (LEED), and scanning tunnelling microscopy (STM) measurements, and by modelling using density functional theory (DFT). | |

And magnesium too... |

|

| With this information at hand, the Australian team also decided to investigate if magnesium – which is notoriously difficult to inject into the graphite structure – could be inserted (intercalated) into graphene on a silicon-carbide substrate. | |

| To the researchers’ surprise, magnesium behaved remarkably similarly to calcium, and also injected between the graphene and substrate, again ‘floating’ the graphene. | |

| Both magnesium- and calcium-intercalated graphene n-type doped the graphene, and resulted in a low workfunction graphene, an attractive aspect when using graphene as a conducting electrical contact for other materials. | |

| But unlike calcium, magnesium-intercalated graphene remained stable in ambient atmosphere for at least 6 hours, overcoming a major technical hurdle for alkali and alkaline earth intercalated graphene. | |

| “The fact that Mg-QFSBLG is a low workfunction material and n-type dopes the graphene while remaining quite stable in ambient atmosphere is a huge step in the right direction for implementing these novel intercalated materials in technological applications,” explains co-author Prof Michael Fuhrer. | |

| “Magnesium-intercalated graphene could be a stepping stone towards discovery of other similarly stable intercalants.” |

| Source: ARC Centre of Excellence in Future Low-Energy Electronics Technologies (FLEET) | |

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |