| Jun 09, 2021 |

Control over water friction with 2D materials towards 'smart' membranes

(Nanowerk News) Speed of water flow is a limiting factor in many membrane-based industrial processes, including desalination, molecular separation and osmotic power generation.

|

|

Researchers at The University of Manchester’s National Graphene Institute (NGI) have published a study in Nature Communications ("Water friction in nanofluidic channels made from two-dimensional crystals") showing a dramatic decrease in friction when water is passed through nanoscale capillaries made of graphene, whereas those with hexagonal boron nitride (hBN) - which has a similar surface topography and crystal structure as graphene - display high friction.

|

|

The team also demonstrated that water velocity could be selectively controlled by covering the high friction hBN channels with graphene, opening the door to greatly increased permeation and efficiency in so-called ‘smart membranes’.

|

|

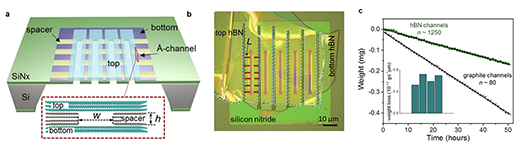

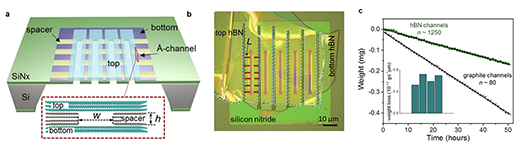

| a Schematics of the capillary devices. b Optical image of a hBN capillary device on a silicon nitride membrane (seen in light green). The top hBN layer is contoured with the dotted curve for visibility. Five parallel rectangular holes (light purple color) open to the other side of the wafer. The direction of the channels underneath the top hBN layer is indicated by the red dotted lines with a defined length L. c Weight loss due to water evaporation through four-layer (h ≈ 1.4 nm) capillaries. The hBN device (green circles) has ∼1250 (±40) parallel channels and the flow is normalized for channel length of L ∼ 1 µm. The graphite device (grey triangles) has ∼15 times fewer channels (n ≈ 80 (±4), average L ≈ 6 µm). The bottom inset shows the weight loss from four different hBN devices normalized per µm channel length. (© Nature Communications) (click on image to enlarge)

|

|

Fast and selective fluid-flows are common in nature – for example in protein structures called aquaporins that transport water between cells in animals and plants. However, the precise mechanisms of fast water-flows across atomically flat surfaces are not fully understood.

|

|

The investigations of the Manchester team, led by Professor Radha Boya, have shown that - in contrast to the widespread belief that all atomically flat surfaces that are hydrophobic should provide little friction for water flow - in fact the friction is mainly governed by electrostatic interactions between flowing molecules and their confining surfaces.

|

|

Dr Ashok Keerthi, first author of the study, said: “Though hBN has a similar water wettability as graphene and MoS2, it surprised us that the flow of water is totally different! Interestingly, roughened graphene surface with few angstroms deep dents/terraces, or atomically corrugated MoS2 surface, did not hinder water flows in nanochannels”.

|

|

Therefore, an atomically smooth surface is not the only reason for frictionless water flow on graphene. Rather the interactions between flowing water molecules and confining 2D materials play a crucial role in imparting the friction to the fluid transport inside nanochannels.

|

Useful in evaporation processes

|

|

Professor Boya said: “We have shown that nanochannels covered with graphene at the exits display enhance water flows. This can be very useful to increase the water flux from membranes, especially in those processes where evaporation is involved, such as distillation or thermal desalination.”

|

|

Understanding of liquid friction and interactions with pore materials is vital to the development of efficient membranes for applications such as energy storage and desalination. This latest study adds to an increasingly influential body of work from the researchers at the NGI, as Manchester reinforces its position at the forefront of nanofluidic research towards improved industrial applications for sectors including wastewater treatment, pharmaceutical production and food and beverages.

|