| Posted: Jun 07, 2017 | |

Carbon nanotube electronic skins for motion detection(Nanowerk News) Researchers in China have developed piezoresistive electronic skins (E-skins) based on a composite of polymer and arrays of aligned few-walled carbon nanotubes (AFWCNTs, with diameter of 3-5 nm) that, enabled by the aligned carbon nanotubes, exhibited multiple advantages, such as simple device structure, high precision, fast response, excellent stability, and low power consumption. |

|

| The team has reported their findings in Advanced Functional Materials ("Versatile Electronic Skins for Motion Detection of Joints Enabled by Aligned Few-Walled Carbon Nanotubes in Flexible Polymer Composites"). | |

|

|

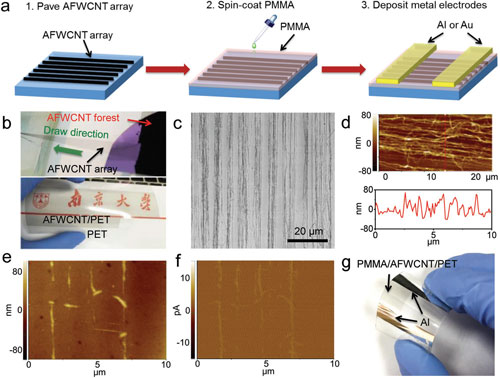

| Fabrication process and morphology of flexion-sensitive E-skins based on PMMA/AFWCNT composite. a) Schematic illustration of the fabrication process. b) Optical images of an AFWCNT array drawn from a FWCNT forest (top) and a bended PET substrate with AFWCNT array attached on the surface (bottom). c) SEM image of AFWCNT array paved on PET after alcohol treatment. d) Topographic AFM image of the surface features of AFWCNT array paved on PET. e) Topographic AFM image of PMMA/AFWCNT composite and f) corresponding conductive AFM image at the bias voltage of 3.0 V. g) Optical image of a bended flexion-sensitive E-skin based on PMMA/AFWCNT composite. (© Wiley-VCH Verlag) (click on image to enlarge) | |

| Piezoresistive E-skins consisting of composite elastomers have received a great amount of attention due to their inherent flexibility, precision, chemical stability, and their simple, scalable, and cost-effective fabrication processes | |

| It is expected that these novel devices with anisotropic sensing capabilities could be a promising candidate for applications in future bionic robots and wearable smart detectors. | |

| What the researchers demonstrated in this work is that the AFWCNTs can serve as efficient anisotropic conductive fillers better than randomly dispersed CNTs in flexible composites for the fabrication of high-performance E-skins. | |

| In their paper, the authors point out that the as-prepared semitransparent flexion-sensitive E-skin possesses many advantages, including high fatigue durability, high precision, low power consumption (<10 µW), and simple fabrication process. | |

| In addition to flexion-sensitive E-skin, the polymer/AFWCNT composites can also be applied for constructing tensile-sensitive E-skins for the detection of stretching with large extension ratios. |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |