| Posted: Jul 12, 2017 | |

Biodegradable temperature sensors for the Internet of Things(Nanowerk News) Materials that undergo degradation by biological and/or chemical processes are used for food packaging, drug delivery, tissue engineering, microfluidics, medical tools, and implantable devices. |

|

| Degradable forms of electronics, i.e., devices that work for a prescribed time and then disappear via hydrolysis or biochemical reactions, could add intelligence and increase the functionalities of these systems. | |

| In a new paper in Advanced Functional Materials ("Biodegradable and Highly Deformable Temperature Sensors for the Internet of Things"), researchers in Switzerland describe the design and fabrication of fully biodegradable temperature sensors whose layout and ultrathin format confer a dynamic response of 10 ms and high mechanical stability, which is preserved even upon application of high strain load. | |

|

|

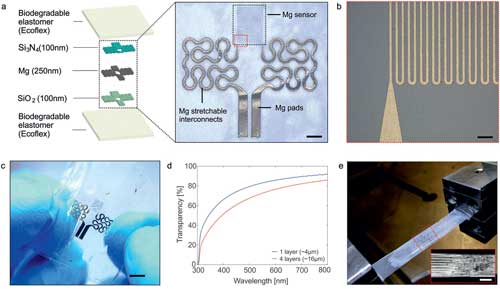

| a) The resistive sensor consists of three main parts: the sensing element which is formed by 10 µm wide serpentine traces, Peano-like interconnects, and the pads for contacting and wiring. The active layer is constituted by 250 nm thick Mg deposited by Radio Frequency sputtering. Thin layers of SiNx, SiOx, and Ecoflex encapsulate the device and place it in the zero strain plane (scale bar 1 mm). The total weight of the device is less than 10 mg. b) Optical image of the junction area between the serpentine traces forming the sensing element and the interconnects (scale bar 50 µm). c) Optical image of the fully biodegradable sensors during bending experiments (scale bar 1 mm). d) Ecoflex thin films possess an optical transparency higher than 50% in the visible spectrum and show a pronounced absorption in the UV region. e) Stretching tests performed on 1 × 6 cm2 stripes of Ecoflex permit to estimate a Young’s modulus of about 500 MPa (scale bar 5 mm). The inset shows a zoom view of the Ecoflex film under test and highlights the buckling effect for large loads. (© Wiley-VCH Verlag) (click on image to enlarge) | |

| The team used magnesium as an active layer while a commercially available polymer acted as encapsulation, given its easy processing, biocompatibility, small swelling rate, and Young’s modulus of 500 MPa. | |

| They integrated an array of sensors onto a fluidic device made of the same polymer to yield a smart biodegradable system for flow mapping. | |

| The assembly scheme proposed by the team is scalable as demonstrated by the integration of an array of nine sensors onto an Ecoflex-based fluidic device that provides an example of monolithic, fully biodegradable device for liquid flow mapping. | |

| Proper encapsulation extended stable electrical operation to 1 day while the connection to a Bluetooth module enables wireless functionalities with 200 mK resolution prospecting application in food tracking and in medical postsurgery monitoring. |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |