| Posted: Sep 05, 2017 | |

Detection of counterfeit food products(Nanowerk News) Globally traded food and pharmaceutical products must fulfill strict quality criteria. However, potentially harmful products still appear on the market, raising serious public health concerns. Such products are either manufactured in substandard quality – a typical feature of counterfeit products – or undesired properties develop during inappropriate storage. |

|

| In a new paper in Small ("Biodegradable Microparticles for Simultaneous Detection of Counterfeit and Deteriorated Edible Products"), researchers report multifunctional hydrogel microparticles bearing a spatially patterned binary authenticity code capable of tagging 4.3 × 109 distinct products and two integrated sensors reporting the product safety. | |

| The research team in The Netherlands developed a flow lithography process for manufacturing microparticles integrating authenticity and sensory functions, with nonharmful biodegradable chemicals. | |

| By careful choice of implemented chemistry, they avoided the commonly used UV irradiation in the lithographic process and replaced it with visible light. Synthesis of the microparticles with visible light brings about flexibility in experimental design (choice of microscope objectives, light source) and facilitates loading the hydrogels with a UV sensitive cargo, such as living cells or UV-cleavable drugs. | |

| The ratiometric fluorescent pH sensor detects pH changes in tagged liquid products attributed to bacterial contamination – a common procedure in microbiology. The storage temperature sensor identifies products stored outside recommended storage temperature. | |

|

|

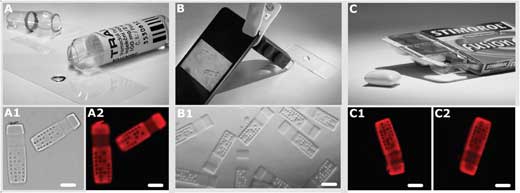

| Model food and pharmaceutical products tagged with postsynthesis UV treated microparticles. A) Labeled intravenous solution of Tramadol painkiller, transmission (A1) and fluorescence (A2) images of microparticles dispersed inside the solution. B) Particles in solution are visualized using a low-cost microscope attached to a smartphone (B1). C) Labeled chewing gum and fluorescence microphotographs of particles on its surface (C1, C2). Scale bars correspond to 50 µm in (B1), and to 20 µm in all other images. (© Wiley-VCH Verlag) (click on image to enlarge) | |

| The team points out that their sensor can even detect short time (approximately several hours) exposure of the tagged product to elevated temperature and reports this information by permanent change of the particle shape. | |

| Owing to the biocompatible and biodegradable substrates used in the microfluidic synthesis, the microparticles can be placed directly on/into the edible products, providing orthogonal and more difficult to bypass security over current technologies placed on the package. | |

| The team demonstrated that the developed microparticles are suitable for labeling solid and liquid formulations of model food and pharmaceutical products. | |

| The microparticles were visualized using a standard fluorescent microscope and a smartphone equipped with a low-cost lens attachment. | |

| "The detection of microparticles with a common portable microscope enables rapid authenticity and product safety verification directly prior to consumption by consumers," the authors conclude their report. "We believe that the developed proof-of-concept multifunctional microparticles may bring about a new integrated solution in addressing the global challenge of protecting customers from consuming counterfeit and deteriorated products." |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |