| Posted: Oct 07, 2017 | |

Robocasting metal-organic framework materials into practical configuration(Nanowerk News) Metal-organic frameworks (MOFs) with tunable physical, structural, and chemical properties have shown outstanding performance as adsorbents, membranes, and catalysts. To enable their industrial gas separation use, they should be properly shaped into suitable contactors. |

|

| Using 3D-printing techniques, researchers have fabricated two types of 3D-printed MOF monoliths from MOF-74(Ni) and UTSA-16(Co). The obtained structures were physically and structurally characterized and compared with the MOF powders. | |

| In addition, we demonstrated their use in gas adsorption processes, in particular in the removal of CO2 from enclosed environments, by performing equilibrium and dynamic adsorption experiments. | |

| In a preliminary investigation, reported in ACS Applied Materials & Interfaces ("3D-Printed Metal–Organic Framework Monoliths for Gas Adsorption Processes"),researchers investigated the application of the 3D printing technique to formulate MOF adsorbents into monolithic contactors that could eventually be applied to large-scale applications. | |

|

|

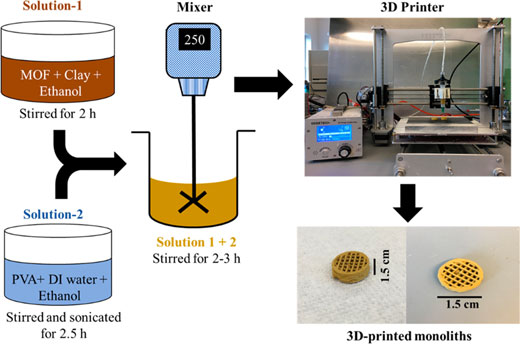

| Schematic of the 3D-printed MOF monolith preparation procedure. (© ACS) | |

| The team from Missouri University of Science and Technology 3D-printed MOF-74(Ni) and UTSA-16(Co) monoliths with MOF loadings as high as 80 and 85 wt %, respectively, and investigated for CO2 removal from air. | |

| They evaluated the physical, structural, and mechanical properties of 3D-printed monoliths and compared them to those of their powder counterparts. The obtained results reveal that the monoliths fabricated by the 3D printing technique retain their physical properties and mechanical integrity. | |

| In addition, the 3D-printed MOF-74(Ni) and UTSA-16(Co) monoliths exhibited CO2 capture capacities comparable to those of the MOF powders with stable performance and relatively faster adsorption kinetics. | |

| "Although more work needs to be done to optimize the formulation and fine-tune the characteristics of the monoliths, we believe this work provides a new proof-of-concept prospect for fabricating MOF monoliths that can be used for various adsorptive-based separation processes," the authors conclude their report. |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |