| Posted: Mar 12, 2018 | |

3D-printing ink highly loaded with iron oxide nanoparticles(Nanowerk News) Researchers in Turkey report the preparation and 3D printing of highly loaded iron oxide (Fe3O4) inks through the minimum use of a single additive that is specifically designed for iron oxide (ACS Applied Materials & Interfaces, "Single Additive Enables 3D Printing of Highly Loaded Iron Oxide Suspensions"). |

|

| Iron oxide is a soft magnetic material with relatively high saturation magnetization, low electrical conductivity, high permeability, and easy magnetization/demagnetization properties which make it a material of choice for applications such as the cores of inductive coils, drug delivery systems, and wastewater treatment. | |

| A particular sub-branch of 3D printing is extrusion-based printing of metallic and ceramic colloidal materials, where highly concentrated suspensions of particles are deposited to construct near-net shaped parts with complex geometries. | |

| Highly loaded suspensions that are to be used as inks for 3D printing can only be achieved through careful tailoring of additives that can cater the properties of each type of particle. | |

| The level of loading that is attained in this work (∼81 wt% of iron oxise nanoparticles), eliminates the need for material removal steps and offers, for the first time in literature, a magnetic ink that contains the highest loadings of particles with a minimum amount of a single additive (1.15 wt%). | |

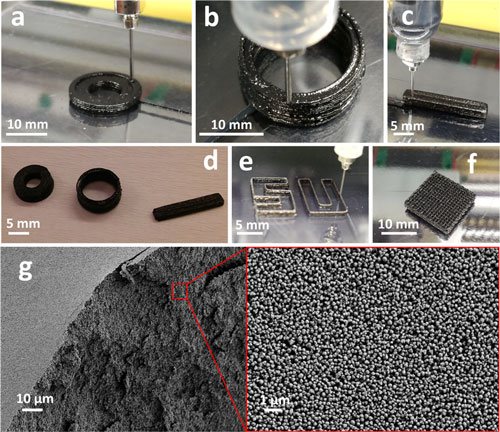

| To demonstrate the printability of various geometries, the researchers printed three different shapes of magnetic cores (rectangular, thick-walled toroidal, and thin-walled toroidal) and a porous lattice structure. | |

|

|

| 3D printing of the magnetic cores: (a) thick-walled toroidal, (b) thin-walled toroidal, and (c) rectangular shapes; (d) dried cores after printing, (e) one-layer thick pattern of “SU” letters, (f) porous structure, and (g) SEM of the fractured surface of the porous structure that is shown in (f). (© ACS) (click on image to enlarge) | |

| They then The electrical and magnetic properties of the magnetic cores are characterized through impedance spectroscopy (IS) and vibrating sample magnetometry (VSM), respectively. The IS indicates the possibility of utilizing wire-wound 3D printed cores as the inductive coils. The VSM verifies that the magnetic properties of IOPs before and after the ink formulation are kept almost unchanged because of the low dosage of the additive. | |

| They point out that this fully aqueous system has the potential to pave the way for domestic printing of ceramics. | |

| "The particle-specific approach that is described for iron oxide provides a solid route to expand the limited portfolio of 3D printing inks," the authors conclude. |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |