| Posted: May 22, 2018 | |

Nanotechnology food packaging releases preservatives on demand(Nanowerk News) FAO, the Food and Agriculture Organization of the United Nations, estimates the yearly global post-harvest food loss and waste by quantity at roughly 30 percent of cereals, 40 –50 percent of root crops, fruits and vegetables, 20 percent of oilseeds, meat and dairy products, and 35 percent of fish. |

|

| At the same time, there are an increasing number of reports that indicate that the consumption of some food preservatives could cause health problems. | |

| Therefore, an ideal preservative should meet three main criteria: to control ripening; to have antimicrobial activity; and finally, the preservative should not be directly in touch with the fruit but should be made available on demand. | |

| Addressing this issue, nanotechnology researchers in India have developed a packaging material that meets the above three criteria. They report their findings in ACS Applied Materials & Interfaces ("Ecofriendly Fruit Switches: Graphene Oxide-Based Wrapper for Programmed Fruit Preservative Delivery To Extend Shelf Life"). | |

|

|

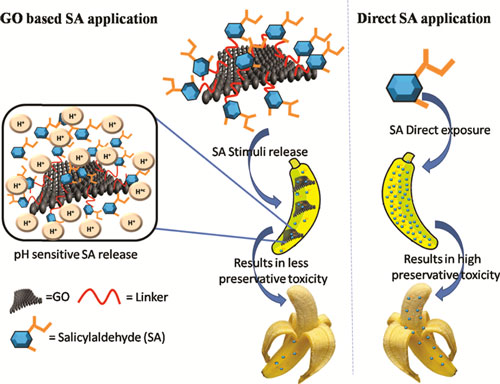

| In this study, acid synthesized in the overripe fruits was envisaged to cleave acid labile hydrazone to release preservative salicylaldehyde from graphene oxide (GO). To maximize loading and to overcome the challenge of GO reduction by hydrazine, two-step activation with ethylenediamine and 4-nitrophenyl chloroformate respectively, are followed. The final composite shows efficient preservative release with the stimuli of the overripe fruit juice and improves the fruit shelf life. (Reprinted with permission from American Chemical Society) (click on image to enlarge) | |

| In their work, the team demonstrates fruit preservative delivery from the nanopacking in response to the signal from the fruit stimuli. They chose graphene oxide (GO) as an inert platform with a very high surface area to accommodate maximum preservative. | |

| They loaded this platform with the model preservative salicylaldehyde. In addition, the surface area of GO can complement in ethylene sequestration, which has been the primary signal from the ripening fruits and in cold stress, to induce oxidation. | |

| Further, the scientists demonstrated the ability of their GO composite material to serve as a fruit preservative carrier for multiple times. | |

| To avoid the environmental risk of the GO-based composite through direct fruit application, they prepared a stable membrane of the composite through vacuum filtration with porous filter paper support. | |

| The researchers caution, thoug, that this composite material may have limitation in the very later stage of overripening, as the acid content will reduce and the late polymerization will form a lignin. They plan to address this issue in their next steps. |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |