| Posted: Jun 21, 2018 | |

Adaptive 3D printing for the fabrication of multifunctional devices on moving freeform surfaces(Nanowerk News) Researchers at the University of Minnesota report a new method for, termed adaptive 3D printing, for the fabrication of multifunctional devices on moving freeform surfaces (Advanced Materials, "3D Printed Functional and Biological Materials on Moving Freeform Surfaces"). |

|

| The motivation is to establish a workflow for on-body devices that is autonomous, requires minimal human intervention, and is ambient-processable without the requirement of being tethered to a microfabrication facility. | |

| Specifically, this method integrates a closed-loop feedback control system onto a compact and portable extrusion-based 3D printer. | |

|

|

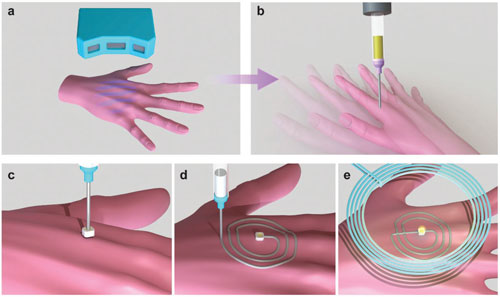

| Figure 1: Adaptive 3D printing of multifunctional devices. Schematic images of: a) 3D scanning of the target surface to be printed on, and b) real-time tracking of the rigid-body motion of the target surface. Schematic images of c) pick-and-place of discrete electronic components on the target surface using a vacuum nozzle, d) direct writing of conductive ink, and e) demonstration of powering the LED via a wireless power transmission system. (Reprinted with permission by Wiley-VCH Verlag) (click on image to enlarge) | |

| The figure above illustrates the fabrication process: The geometric information of the target surface is first acquired in the form of a dense point cloud via a structured light scanner (Figure 1a). | |

| The sampled geometric information is then combined with a real-time estimation of the rigid-body motion of the target surface (Figure 1b), and as a whole fed back to the motion controller for adaptive 3D printing. | |

| During printing, a discrete electronic component, such as a surface-mounted LED, is first pick-and-placed onto the target surface automatically (Figure 1c). | |

| Functional inks, such as conductive and insulator inks, are directly printed onto the moving target surface to create electronic circuits (Figure 1d). The printed devices are finally dried at room temperature and powered by a wireless transmission system (Figure 1e). | |

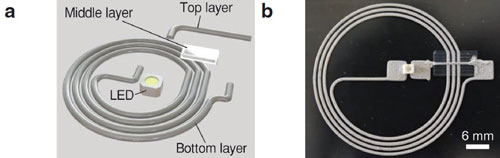

| To demonstrate the performance of the conductive ink in wireless electronic devices, the researchers fabricated inductive coils to power automatically pick-and-placed LEDs (Figure 2a), with the image of a final device shown in Figure 2b. The wireless device was fabricated layer-by-layer, consisting of an inductive coil at the bottom, an insulator layer in the middle, a crossover conductive trace at the top, and a surface-mounted LED as the electrical load of the circuit. | |

|

|

| Figure 2. Characterization of the wireless devices and the adaptive printing system. a) Layout of the layered design of the 3D printed wireless device that powers a surface-mounted LED. b) Photograph of the printed wireless device. (Reprinted with permission by Wiley-VCH Verlag) | |

| The team also demonstrated the fabrication of wirelessly powered devices and wireless moisture sensors on human hands, via 3D printing a novel functional, fast drying ink that is highly conductive, room-temperature processable, and flexible. | |

| Future studies by the team will focus on the following: 1) Optimizing the adaptive printing system to reduce printing time and improve printing fidelity for fine and more sophisticated electronics; 2) integrating multifunctional electronic components in the wirelessly powered devices for active biomachine interfacing; 3) optimizing the moisture sensor as a sweat sensor for wireless monitoring of physical exertion or stress levels; 4) printing layered structures of gene-corrected cells as skin substitutes, for in vivo studies on improved wound healing; 5) applying adaptive printing to insects and animals for large-scale production of cyborgs as self-distributed data collectors in ecosystems. | |

| "Overall, by incorporating a diverse palette of high quality electrical and biological materials with the adaptive 3D printing platform, new possibilities will be created in the wearable device industry, in biological and biomedical research, and in the study and treatment of health conditions," the researchers conclude their report. |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |