| Apr 18, 2019 | |

3D printing complete energy storage architectures(Nanowerk News) Many of the current 3D-printed energy storage systems, such as 3D-printed lithium-ion batteries, utilize a direct-write technology, where the print is formed of a fluidic compound, printed layer-by- layer, before requiring curing, by either heat, UV exposure or nitrogen freezing. This curing/freezing is required to solidify the printed model, resulting in a system that is highly restricted in the vertical z-direction, and experience significant warping and shrinkage. |

|

| Reporting their findings in Advanced Energy Materials ("Next-Generation Additive Manufacturing of Complete Standalone Sodium-Ion Energy Storage Architectures"), researcher have demonstrated the first freestanding sodium-ion (full cell) battery formed entirely of components that have been fabricated via 3D printing. | |

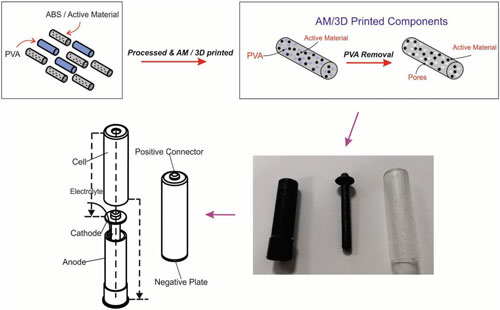

| This approach is a novel and contemporary solution for the development of the next generation of energy storage systems integrating the active materials NaMnO2 and TiO2 within a highly novel porous supporting material, designed to maximize electrode surface area, before being AM/3D printed into a proof-of-concept model based upon the basic geometry of a commercially available AA battery. | |

|

|

| Schematic illustration and photographs of the fabrication procedure of the complete freestanding fully 3D printed sodium-ion battery. (Reprinted with permission by Wiley-VCH Verlag) (click on image to enlarge) | |

| The team's energy storage architecture is developed entirely using 3D printed components. In order to do this, the active battery materials have to be integrated into a porous polymer matrix; without this, the electrolyte cannot penetrate the active components and the lack of a triple-phase boundary means that an 3D printed structure without porosity, is a poor/completely useless battery. | |

| Therefore, the researchers developed a porous polymer matrix by integrating an immiscible water-soluble polymer into an 3D printable polymer matrix. In this case, PVA is mixed into an ABS polymer matrix along with the active materials, NaMnO2 for the cathode, and a TiO2 nanopowder for the anode, along with the inclusion of Super P nanocarbon in order to enhance the electrochemical conductivity. | |

| The resulting composites are extruded into 3D printable filaments and manufactured via FDM 3D printing an appropriate electrode design/energy storage architectures. | |

| The 3D printed electrodes are then sonicated in water for 4 hours to remove the micropockets of PVA (as PVA is easily dissolvable within water), leaving microporous electrochemically active 3D printed electrodes/energy storage architectures. The resulting electrode/structure is dried at 60°C and stored under vacuum. | |

| The 3D printed devices demonstrate a respectable performance of 84.3 mAh g-1. |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |