| Apr 22, 2019 | |

Printing self-powered sensor systems on plastic(Nanowerk News) Printable electronics has emerged as a new class of devices complementing those manufactured by conventional technologies, such as lithographic technique based silicon electronics, mainly due to its relatively facile and low cost fabrication procedures, as well as desirable scalability and versatility in device designs. |

|

| In recent work, researchers in China have demonstrated the concept of a printable and wearable self-powered sensor system for ethanol/acetone detection. | |

| This is the first report (Advanced Materials, "Printable Fabrication of a Fully Integrated and Self-Powered Sensor System on Plastic Substrates") on a monolithically and fully integrated system that was successfully constructed on flexible plastic substrate in ambient environment by utilizing additive inkjet printing. | |

|

|

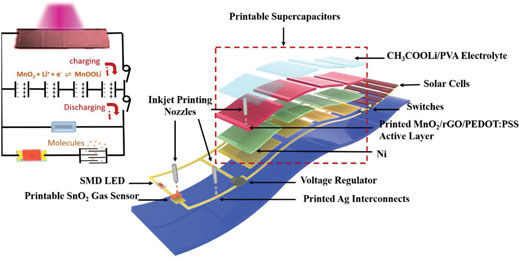

| Schematic images of printable fabrication procedures and system operational mechanism (inset) of the flexible and wearable monolithically integrated self-powered smart sensor system on plastic substrate. (Reprinted with permission by Wiley-VCH Verlag) (click on image to enlarge) | |

| The team's wearable wristband mainly consists of inkjet-printed electrical interconnects, silicon solar cells for energy harvesting/conversion, printable MnO2-based planar supercapacitors for energy storage, and fully printable SnO2 gas sensor for ethanol/acetone detection. | |

| With the supercapacitors serving as photovoltaic energy storage units and providing power for the functional devices during intermittent light illumination, simultaneous functionality without external charging modules can be realized, which is highly desirable for wearable and portable electronics. | |

|

|

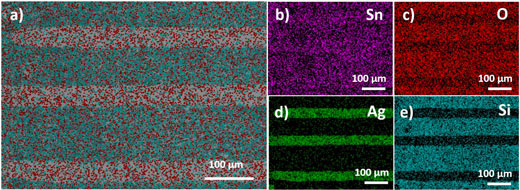

| EDS images a-e) of fully printable SnO2 gas sensor with interdigitated electrodes. Reprinted with permission by Wiley-VCH Verlag) | |

| The team synthesized and prepared different functional nanoparticles into printable inks for the fabrication of supercapacitors and gas sensors. | |

| The printable fabrication methodology developed in this work demonstrates its facileness and scalability for both device fabrication and system integration. The authors conclude thatsuch a concept demonstration of a printable integrated self-powered sensor system can inspire future additive fabrication of a wide variety of wearable and portable devices, especially for personalized healthcare, biomedical monitor applications. |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |