| Apr 26, 2019 | |

3D printing micro-electromechanical switches(Nanowerk News) Researchers have demonstrated the facile fabrication of two-terminal micro-electromechanical (MEM) switches using a commercially available fused deposition modeling (FDM)-based 3D printer. |

|

| As the team from South Korea reports in ACS Applied Materials & Interfaces ("Three-Dimensionally Printed Micro-electromechanical Switches"), they fabricated MEM switches in a single printing step using 3D-printable thermoplastic materials. | |

|

|

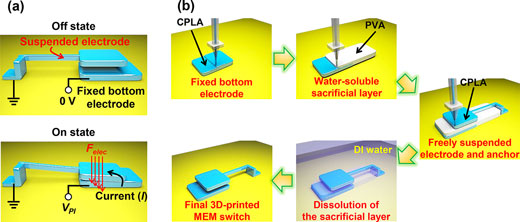

| (a) Schematic illustrations of a 3D-printed two-terminal MEM switch in the nonconducting off state and in the conducting on state. The MEM switch exhibits a pull-in phenomenon because of the electrostatic force acting on the suspended electrode when voltage is applied to the fixed bottom electrode. (b) Process flow for the fabrication of a 3D-printed two-terminal MEM switch. First, a CPLA layer was printed to form a fixed bottom electrode. A PVA layer was then printed on the CPLA as a water-soluble sacrificial layer. Then, another layer of CPLA was printed to form a freely suspended electrode with a hammerhead structure. Finally, the PVA layer was dissolved in DI water to achieve the mechanical separation of the electrodes, yielding the final 3D-printed two-terminal MEM switch. (Reprinted with permission by American Chemical Society) (click on image to enlarge) | |

| FDM is commonly used as the printing method in 3D printers, allows for the fabrication of parts using a range of materials, including elastomers and polymers. | |

| FDM is an additive manufacturing technology through which thermoplastic materials are melted by a heating coil in an extruder, are laminated layer by layer, and are hardened by a fan operating on each side of the work area to produce tangible objects. | |

| The team's 3D-printed MEM switch design has a two-terminal structure with a freely suspended upper electrode and a fixed lower electrode printed from CPLA. In addition, to achieve the physical separation of the two electrodes, a layer of water-soluble PVA was printed between the electrodes. | |

|

|

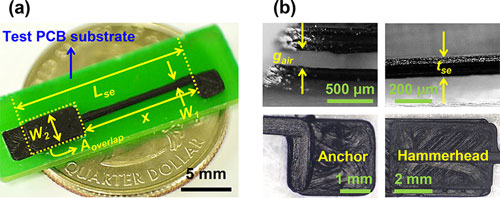

| (a) A 3D-printed two-terminal MEM switch with a freely suspended electrode fabricated on a PCB substrate. (b) Magnified views of key components of the 3D-printed MEM switch: the gair after the removal of the sacrificial PVA layer, the thickness tse of the suspended electrode, the anchor supporting the suspended electrode, and the hammerhead structure of the suspended electrode. (Reprinted with permission by American Chemical Society) (click on image to enlarge) | |

| The authors point out that this 3D-printed MEM switches exhibit excellent electromechanical properties in both the on and off states, showing promise for the applicability of 3D-printed electronic devices. Consequently, 3D-printed MEM switches are intriguing candidates for the implementation of high-throughput and low-cost MEM devices. |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |