| Mar 30, 2022 |

Artificial spider silk with a toughness equal to dragline silks can now be spun

|

|

(Nanowerk News) Using spiders to produce spider silk on an industrial scale is impossible, but it is possible to use bacteria for production of shorter versions of spider silk proteins that can be isolated and spun into fibres.

|

|

A team led by researchers at SLU and KI in Sweden has now designed artificial spider silk proteins with properties that not even spiders can achieve, and the fibres they have spun are equally tough as the spider’s silk. The yield is also in line with what is required for industrial production.

|

|

These results were recently published in the journal Advanced Functional Materials ("Engineered spider silk proteins for biomimetic spinning of fibers with toughness equal to dragline silks"), by an international research group led by professor Anna Rising from the Swedish University of Agricultural Sciences (SLU) and Karolinska Institutet (KI), and Jan Johansson from KI.

|

|

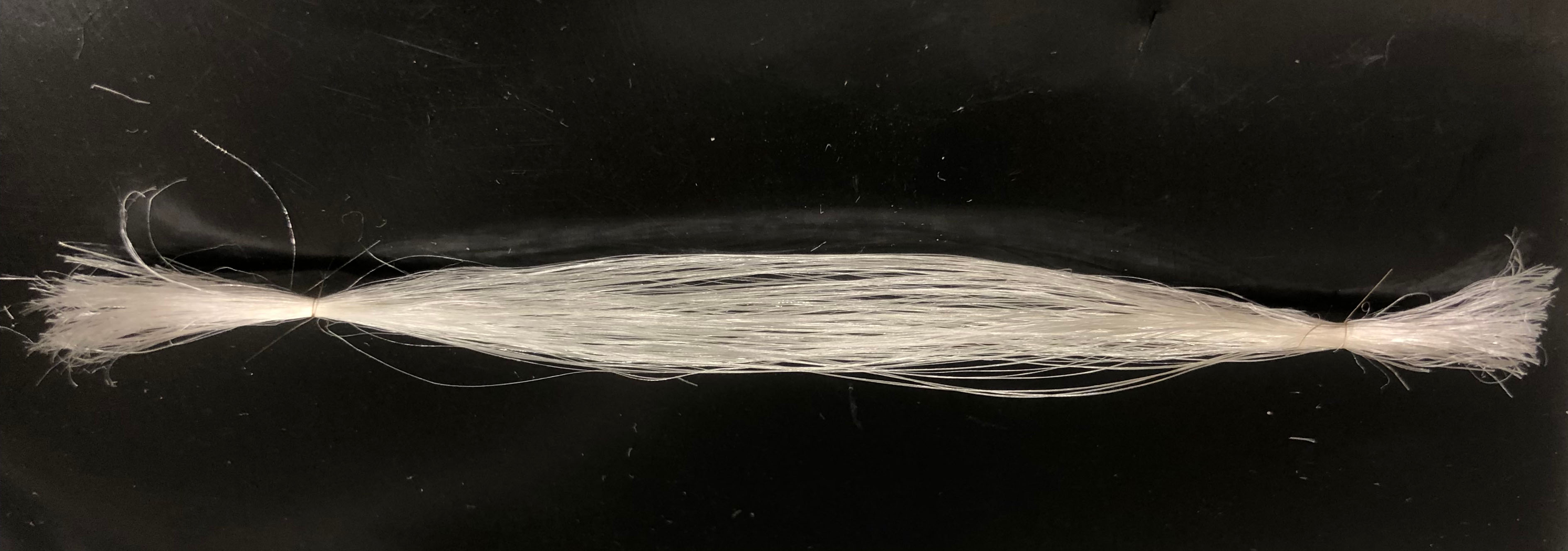

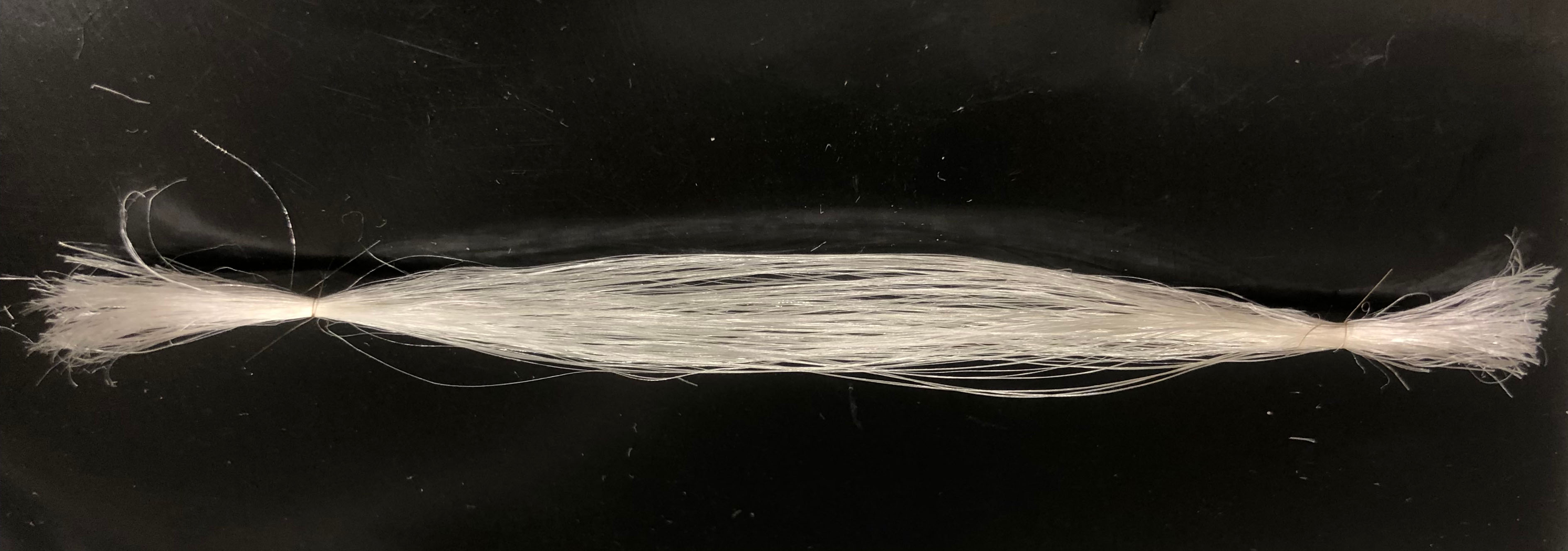

| A bundle of artificial spider silk spun by the research team. (Image: Marlene Andersson)

|

|

Spider silk is the toughest fibre found in nature, and bulk production of artificial spider silk that matches its mechanical properties remains elusive. The development of miniature spider silk proteins (mini-spidroins) has made large-scale fibre production economically feasible, but these fibres’ mechanical properties are inferior to native silk.

|

Properties that not even spiders can achieve

|

|

To increase the artificial silk fibres’ mechanical properties, Anna Rising and her colleagues did what nature itself cannot do, by using insights into basic biological principles and protein engineering. The spider silk fibre’s tensile strength is conferred by protein segments that are tightly packed and zipped together.

|

|

Spider silk proteins are secreted from the cells of the silk gland and they must be void of long stretches of hydrophobic residues, since such segments get stuck in membranes inside the cell. At the same time, the researchers realised that such hydrophobic residues could mediate tighter interactions in the protein zippers, features that are attractive for the generation of strong artificial silks.

|

|

Producing these designed proteins in bacteria is a way to circumvent the biological laws that spiders must obey, since bacteria lack the membranes that can trap the proteins in the cell. Building on these insights the research team designed spider silk proteins that were predicted to form stronger zippers and successfully produced a panel of these in bacteria.

|

As tough as natural spider silk

|

|

Using a simple but very effective and nature-mimicking (biomimetic) spinning device, the team managed to produce fibres with increased tensile strength and two fibre types displayed toughness equal to native dragline silks.

|

|

“When growing the bacteria in a bioreactor, we were able to produce about 9 grams of protein per litre, which is in line with requirements for an economically viable industrial bulk scale production”, says Anna Rising. “The proteins we get from one litre of bacterial culture would be enough to spin an 18 km long fibre”.

|