| Apr 11, 2023 |

Bioprinting technology combined with artificial intelligence allows to obtain high quality in vitro models

|

|

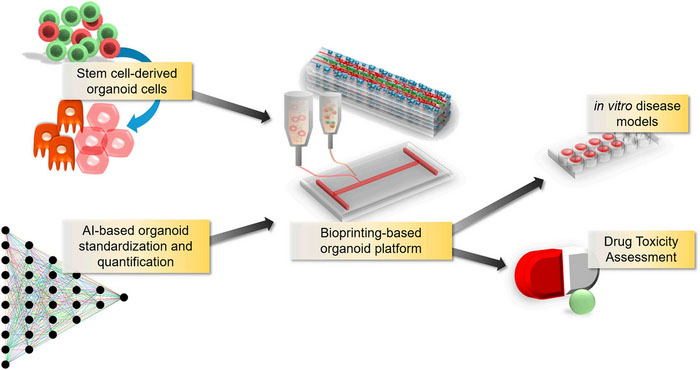

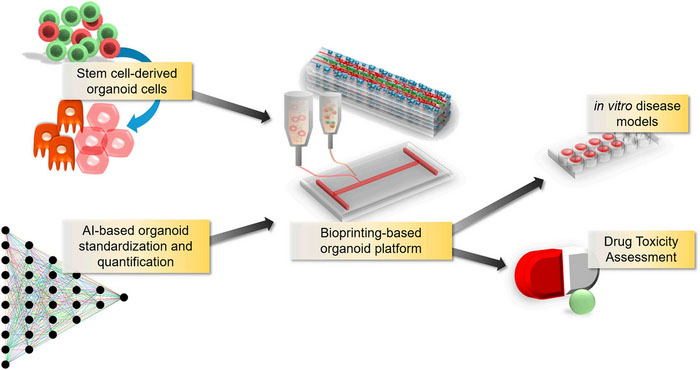

(Nanowerk News) In the realm of organoid production, bioprinting technology not only streamlines the creation and maintenance of intricate 3D biological shapes and structures but also enables standardization and quality control throughout the process. When combined with artificial intelligence, which can assess product potential during manufacturing, a more consistent source of viable, functional cells for organoids can be achieved.

|

|

In essence, the fusion of bioprinting and artificial intelligence is anticipated to enable real-time diagnostics of organoids, ultimately resulting in high-quality, uniform in vitro models.

|

|

Professor Hyungseok Lee of Kangwon National University's Department of Mechanical and Biomedical Engineering shared his insights on the future of organoid manufacturing in Cyborg and Bionic Systems ("Engineering In vitro Models: Bioprinting of Organoids with Artificial Intelligence").

|

|

| Standardized organoid produced by bioprinting combined with artificial intelligence promises to replace experimental animals as disease models and for drug screening. (Image: Dr. Hyungseok Lee)

|

|

Organoids, which possess the ability to self-organize and assemble, offer extensive research and application potential. Beyond simulating human organ development in a way that animal models cannot, organoids can also replicate human pathology for research purposes. Furthermore, the ease of customizing cell sources allows organoids to serve as personalized proxies for clinical patients, helping to predict the most effective therapeutic agents.

|

|

However, standardizing organoid production remains a challenge due to variations in researchers, culture conditions, and cellular environments. Though organoids enable disease modeling, they cannot consistently display the properties necessary for new drug screening, particularly during quantification. Maintaining a constant equilibrium of nutrients, growth factors, and metabolites during organoid growth is another technical hurdle, potentially leading to discrepancies with the intended target tissue.

|

|

Bioprinting, specifically extrusion bioprinting, permits standardized production of organoids with complex cellular compositions and structures while minimizing human intervention and ensuring quality control. Additionally, bioprinting technology can facilitate the automation of manufacturing processes. High resolution is crucial for bioprinting organoids, paving the way for the development of vascularized organoids with perfusion networks that overcome the limitations of passive substance transport.

|

|

Artificial intelligence, which is currently gaining recognition for its capacity to monitor and regulate the quality of final products, can be integrated into the bioprinting process to create organoids. By monitoring cell status and printed structures in real time, AI provides feedback for precise printing, ensuring high resolution. This innovative approach to organ manufacturing holds promise for modeling complex diseases and conducting combinatorial testing of new drugs.

|