| Jul 16, 2018 |

First rare earth-free MnAlC permanent magnet filaments for 3D printing

|

|

(Nanowerk News) The first fabrication of rare-earth-free MnAl-based continuous filaments with permanent magnet properties has been achieved. The research by Dr. Alberto Bollero’s group at IMDEA Nanociencia (Spain) and the company Höganäs (Sweden) holds promise for its implementation in advanced 3D printing of high-performance magnets for energy, automotive and aerospace applications.

|

|

Magnets are key elements of the present and future technology: mobile phones, household appliances, cars, planes, engines. These technological applications require of magnets capable of generating an elevated magnetic field in a small volume, optimizing the space for reduced and light devices.

|

|

A limited number of permanent magnets, which nowadays are based on rare-earth elements, comply with this requirement.

|

|

The obstacles for finding resources of rare-earths together with the environmental impact of their extraction and posterior refining have triggered new routes for finding rare-earth-free solutions.

|

|

The Group of Permanent Magnets and Applications at IMDEA Nanociencia led by Dr. Alberto Bollero, is currently investigating the possibilities that rare earth-free magnets may offer, by covering novel materials development and recycling issues (Acta Materialia, "Severe tuning of permanent magnet properties in gas-atomized MnAl powder by controlled nanostructuring and phase transformation" and ACS Sustainable Chemistry & Engineering, "Recycling of Strontium Ferrite Waste in a Permanent Magnet Manufacturing Plant").

|

|

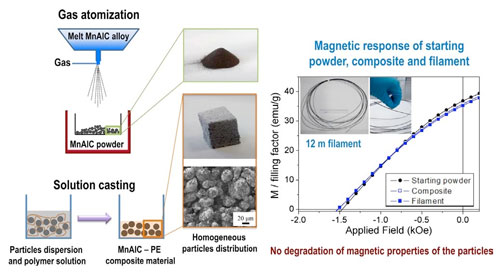

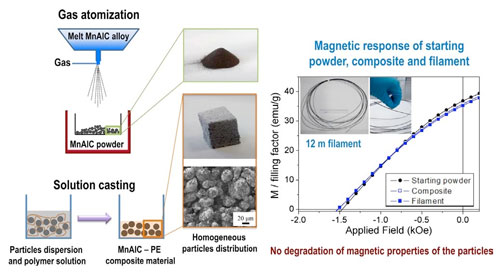

| Scheme of the synthesis of composites made of gas-atomized MnAl-based particles together with images of the powder and composite morphology. The magnetic response of the composites and filaments shows no deterioration of the magnetic properties of the starting particles. (click on image to enlarge)

|

|

In addition to the need of searching new rare earth-free alternatives, the group aims to change the actual technological paradigm, based on a design of devices and final products according to components (particularly magnets) with a pre-defined size and shape (in-catalogue availability). With this aim the group at IMDEA has designed an advanced 3D-printing route of composite materials to achieve functional structures avoiding the limitations of traditional manufacturing.

|

|

In the study, MnAlC (Manganese-Aluminum-Carbon alloy) particles –excellent permanent magnet candidate– combined with polymer have been used for fabricating scalable permanent magnet composites and extruded flexible filaments with continuous length exceeding 10 meters (Science and Technology of Advanced Materials, "Development of permanent magnet MnAlC/polymer composites and flexible filament for bonding and 3D-printing technologies").

|

|

With this study, in collaboration with the company Höganäs (Sweden), the group at IMDEA has reported for the first time the synthesis and fabrication of a continuous rare earth-free MnAlC permanent magnet filament with application in bonding and advanced 3D printing technologies. These results open a new path for designing and fabricating devices without restrictions in shape and dimensions and according to efficiency from the point of view of performance, materials usage and diminished environmental impact.

|

|

This research has been done in the frame of the on-going project “NEXMAG”, coordinated by Dr. A. Bollero, which has been designated Success Project Case by the M-era.Net network.

|

|

The work here presented was supported through the projects “NEXMAG” (M-era.Net Programme) and “3D-MAGNETOH” of the Spanish Ministry of Economy, Industry and Competitiveness, and the “NANOFRONTMAG” project by Regional Government of Madrid. IMDEA Nanociencia has received the support of the ‘Severo Ochoa’ Programme for Centres of Excellence in R&D. The research has been conceived under the industrial project GAMMA (Höganäs AB – IMDEA Nanociencia), and will continue its direction with a new industrial collaboration.

|

|

The Group of Permanent Magnets and Applications at IMDEA Nanociencia has begun recently collaborating with the US-based company Urban Mining with the aim of recycling permanent magnet residues. "Closing the loop to guarantee sustainability" is the premise of this collaboration, which will contribute to mitigate the dependency that USA and Europe have on critical raw materials needed for the fabrication of technological permanent magnets.

|

|

This collaboration sums up to the existing industrial projects with national and international companies (IMA S.L.-Barcelona, RAMEM S.A.-Madrid, Höganäs AB-Sweden…) from different technological sectors, thus proving the successful combination of basic and applied research carried out by the Group of Permanent Magnets and Applications at IMDEA Nanociencia.

|