| Sep 02, 2019 |

Fabricating thermally controlled 3D-printed metal/polymer components

|

|

(Nanowerk News) One of the main technological challenges when trying to combine metal particles with polymers for the fabrication of functional composites is the possibility of achieving a high metal concentration dispersed in a suitable polymer.

|

|

Not every polymer is valid for the synthesis of metal-based composites since issues such as solubility are crucial. Challenges extend after the synthesis of the composite to the fabrication of a continuous wire or filament to achieve a high metal content and not just a polymeric product with dispersed metallic particles.

|

|

This is of extreme importance to end with 3D-printed metal/polymer components providing high thermal conductivity (when needed) and mechanical stability in view of practical applications.

|

|

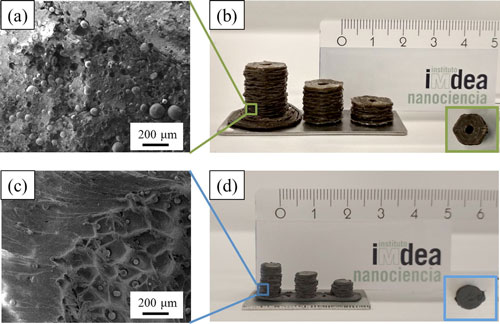

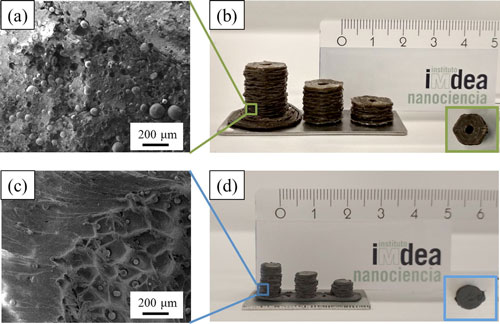

The technological novelty of the work (Composites Part A: Applied Science and Manufacturing, "omposites based on metallic particles and tuned filling factor for 3D-printing by Fused Deposition Modeling") developed by IMDEA Nanociencia and RAMEM comprises: 1) identification of polymers (acrylonitrile butadiene styrene, ABS) adequate to be combined with metallic particles (aluminum and stainless steel) for the synthesis of composites through a scalable method; 2) fabrication of continuous filaments (above 15 m long as proof-of-concept) with high flexibility and a high metal content of 80%; and 3) thermally controlled printing of components using metal/polymer filament, with no need of going to laser assisted methods.

|

|

| 3D printed aluminum- and stainless steel-based columns. (Image: Ester Palmero) (click on image to enlarge)

|

|

This 3D-printing method allows a personalized manufacturing and creation of complex and light geometries.

|

|

The fabrication method proposed by Dr. Palmero and coworkers eliminates manufacturing and postprocessing equipment and tooling, and minimizes material waste, saving in this way significant manufacturing cost.

|

|

Moreover, this thermally controlled 3D-printing method might be combined with standard additive manufacturing technologies for the fabrication of multimaterial and multifunctional metallic components.

|

|

In view of potential technological applications in sectors such as aeronautics and aerospace, this work could open a new path (from the composite synthesis to the 3D-printing process) for the fabrication of pieces with controlled and tuned amount of metallic particles, arbitrary designs, and in consequence, tuned physical properties.

|