| Jul 08, 2020 |

Shock-dissipating 3D-printed fractal cubes could forge high-tech armor

|

|

(Nanowerk News) Tiny, 3D printed cubes of plastic, with intricate fractal voids built into them, have proven to be effective at dissipating shockwaves, potentially leading to new types of lightweight armor and structural materials effective against explosions and impacts.

|

|

“The goal of the work is to manipulate the wave interactions resulting from a shockwave,” said Dana Dattelbaum, a scientist at Los Alamos National Laboratory and lead author on a paper to appear in the journal AIP Advances ("Shockwave dissipation by interface-dominated porous structures"). “The guiding principles for how to do so have not been well defined, certainly less so compared to mechanical deformation of additively manufactured materials. We’re defining those principles, due to advanced, mesoscale manufacturing and design.”

|

|

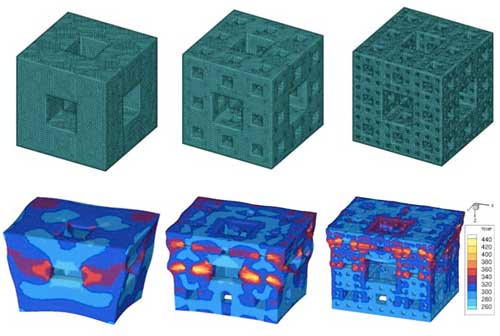

| Simulations show how fractal structures of increasing complexity dissipate energy from shockwaves. (click on image to enlarge)

|

|

Shockwave dispersing materials that take advantage of voids have been developed in the past, but they typically involved random distributions discovered through trial and error. Others have used layers to reverberate shock and release waves. Precisely controlling the location of holes in a material allows the researchers to design, model and test structures that perform as designed, in a reproducible way.

|

|

The researchers tested their fractal structures by firing an impactor into them at approximately 670 miles per hour. The structured cubes dissipated the shocks five times better than solid cubes of the same material.

|

|

Although effective, it’s not clear that the fractal structure is the best shock-dissipating design. The researchers are investigating other void- or interface-based patterns in search of ideal structures to dissipate shocks. New optimization algorithms will guide their work to structures outside of those that consist of regular, repeating structures.

|

|

Potential applications might include structural supports and protective layers for vehicles, helmets, or other human-wearable protection.

|