| Oct 14, 2020 |

First 3D-printed venilator could be available within months

|

|

(Nanowerk News) As many under-resourced parts of the world suffer from a lack of ventilators, Malmö University researchers have joined an international, network that hopes to enable the production of this life-saving equipment at a low cost.

|

|

The aim is to produce designs for some of the key components of the devices which can be used to manufacture the ventilator from 3D-printouts— the designs will be free to download. It is hoped that, after testing, this plan can be rolled out within two years.

|

|

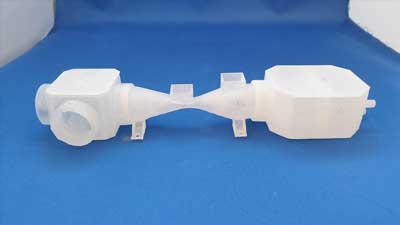

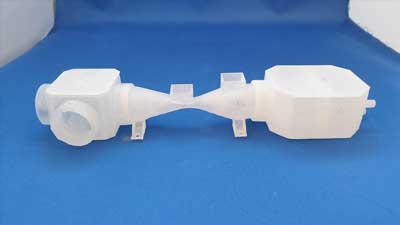

| A component of a life-saving ventilator. (Image: University of Malmö)

|

|

A group of volunteers in various specialist fields, including dentistry, medicine, and engineering, have formed the LibreLabs platform. The action was prompted after COVID-19 showed the need to be able to help patients through the development of new technology. The purpose of the collaboration is to make medical technology accessible to all.

|

|

“The pandemic has shown that the lack of ventilators could be a problem in many parts of the world, for example in my home country of Sri Lanka,” says Manjula Herath, an oral and maxillofacial doctoral student at the Faculty of Dentistry.

|

|

The aim is to make a sustainable and affordable solution that is made available for production in low and middle-income countries, where there is a significant shortage of ventilators.

|

|

“It will be a ventilator that lives up to the European medical technical standard, and that works for long-term use. We are not there yet, but that is our goal," says Herath.

|

|

Together with colleague Lisa Papia, senior lecturer and dental technician, he has developed a design for 3D-prints of some of the key components found in a respirator. Researchers at Trinity College Dublin have contributed with computer simulations.

|

|

In total, about 15 researchers are included in the project. “We produce the drawings and create files. Based on them, you should be able to make ventilators yourself,” says Papia.

|

|

A first prototype will undergo a quality assessment in Peradeniya, Sri Lanka by an independent party to see if the equipment works as intended. Herath and Papia believe that this will be ready within six months.

|

|

Changes will probably need to be made, and they consider it realistic that an approved ventilator can be in place within two years.

|

|

“To be able to get there, we need financing, which is something we are working with. A commercially manufactured ventilator today costs around 10,000 dollars or more, and we believe that ours can be manufactured for around a tenth of that cost," Herath explains.

|