| Jan 22, 2021 |

3D printing to pave the way for Moon colonization

|

|

(Nanowerk News) A research team from the Skoltech Center for Design, Manufacturing, and Materials (CDMM) comprising 2nd year Ph.D. student Maxim Isachenkov, Senior Research Scientist Svyatoslav Chugunov, Professor Iskander Akhatov, and Professor Igor Shishkovsky has prepared an extensive review on the use of Additive Manufacturing (AM) technologies (also known as 3-D-printing) in crewed lunar exploration.

|

|

Their paper published in the journal Acta Astronautica ("Regolith-based additive manufacturing for sustainable development of lunar infrastructure – An overview") contains a comprehensive description of the geological composition of the lunar surface and the properties of lunar soil (lunar regolith) and its simulants, detailing their mineralogy, morphology, and chemical composition in the light of their future use as feedstock for 3-D-printing on the moon surface.

|

|

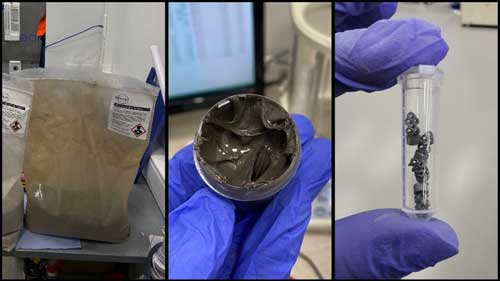

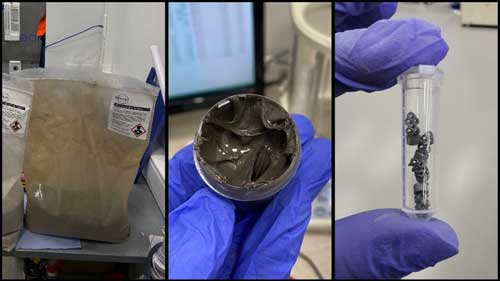

| Figure 1. From left to right: lunar regolith simulants, resulting paste, and stereolithographic printed samples. (Image: Skoltech)

|

|

The authors evaluated different 3-D-printing techniques presented in the literature in terms of their suitability for in-situ manufacturing and maintainability, with a focus on the adaptation of AM methods to low gravity, limited energy consumption, dimension and weight constraints of AM components delivered to the moon, scalability of AM technologies, the low-gravity performance of 3-D-printing methods, and autonomy of AM applications.

|

|

According to Maxim Isachenkov, "3-D-printing technologies will be one of the cornerstones of lunar exploration, providing future astronauts with a required infrastructure, spare parts, and tools via local resources utilization." He believes that "There is no universal 3-D-printing approach capable of dealing with all these tasks. Each approach will have a niche of its own, depending on multiple factors. It would be worthwhile to develop a strategy on how to use a set of AM methods individually or in combination and select a technique best suited for a specific purpose."

|

|

The team hopes that their review will help researchers worldwide find the most promising AM techniques for further research and development and involve more teams in these studies, which could eventually contribute to the sustainable development of the future lunar infrastructure and the expansion of human presence in space.

|

|

The Skoltech scientists led by Prof. Shishkovsky have moved on from analyzing the art's global state in the field and launched their own research. The CDMM Additive Manufacturing Lab has initiated studies on the applicability of various 3-D printing technologies for lunar regolith, emphasizing stereolithography that helps manufacture high-strength precision ceramic parts. The Lab's first samples obtained from a lunar soil simulant developed by NASA's Center for Lunar and Asteroid Surface Science (CLASS) demonstrated that this approach is possible in principle (Fig. 1).

|

|

The Skoltech team plans to manufacture more complex functional products, such as living modules, conduct mechanical tests, and tailor the technology for autonomous operation in lunar gravity.

|