| Feb 04, 2021 |

Dynamic 3D printing process features a light-driven twist

|

|

(Nanowerk News) The speed of light has come to 3D printing. Northwestern University engineers have developed a new method that uses light to improve 3D printing speed and precision while also, in combination with a high-precision robot arm, providing the freedom to move, rotate or dilate each layer as the structure is being built.

|

|

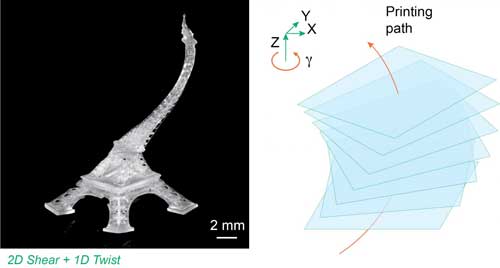

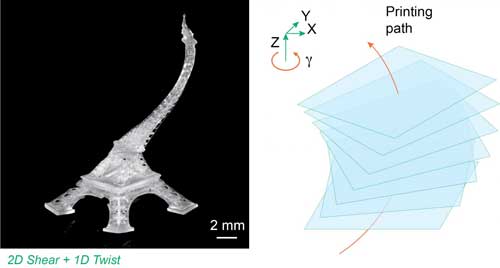

| This tiny Eiffel Tower was produced using a new dynamic 3D printing method that has the ability to change printing direction on the fly. The printing path is shown on the right. (Image: Northwestern University)

|

|

Most conventional 3D printing processes rely on replicating a digital design model that is sliced into layers with the layers printed and assembled upwards like a cake. The Northwestern method introduces the ability to manipulate the original design layer by layer and pivot the printing direction without recreating the model. This "on-the-fly" feature enables the printing of more complicated structures and significantly improves manufacturing flexibility.

|

|

"The 3D printing process is no longer a way to merely make a replica of the designed model," said Cheng Sun, associate professor of mechanical engineering at Northwestern's McCormick School of Engineering. "Now we have a dynamic process that uses light to assemble all the layers but with a high degree of freedom to move each layer along the way."

|

|

Sun led the research, which lies at the intersection of two of his main areas of focus: nanofabrication and optics. The study was published by the journal Advanced Materials ("Conformal Geometry and Multimaterial Additive Manufacturing through Freeform Transformation of Building Layers").

|

|

In the paper, the researchers demonstrate several applications, including 3D printing a customized vascular stent and printing a soft pneumatic gripper made of two different materials, one hard and one soft. A double helix and a tiny Eiffel Tower are two other printed examples in the study.

|

|

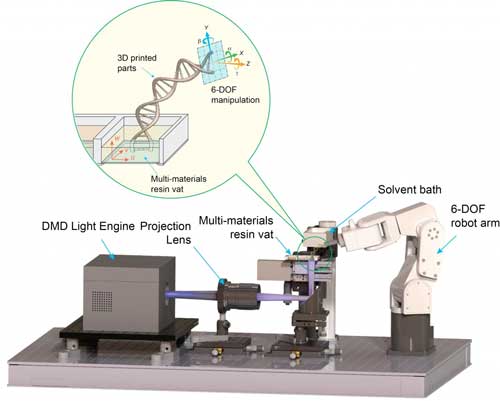

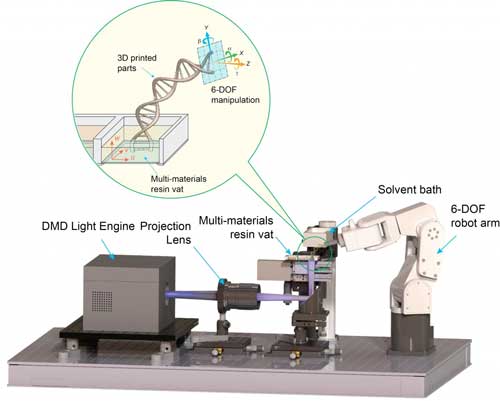

The Northwestern process uses a robotic arm and a liquid photopolymer that is activated by light. Sophisticated 3D structures are pulled out from a bath of liquid resin by a high-precision robot with enhanced geometric complexity, efficiency and quality compared to the traditional printing process. The arm is used to change the printing direction dynamically.

|

|

| The new dynamic 3D printing method developed at Northwestern University uses light and a high-precision robot arm to print a variety of structures. (A double helix is shown). (Image: Northwestern University) (click on image to enlarge)

|

|

"We are using light to do the manufacturing," Sun said. "Shining light on the liquid polymer causes it to crosslink, or polymerize, converting the liquid to a solid. This contributes to the speed and precision of our 3D printing process -- two major challenges that conventional 3D printing is facing."

|

|

The continuous printing process can print 4,000 layers in approximately two minutes.

|

|

"This is a very fast process, and there is no interruption between layers," Sun said. "We hope the manufacturing industry will find benefit in it. The general printing method is compatible with a wide range of materials."

|

|

Looking to the future, Sun said this printing process could be applied to other additive as well as traditional subtractive manufacturing processes, providing a bridge toward a truly hybrid process.

|