| Jun 11, 2021 |

New way to 3D-print custom medical devices to boost performance and bacterial resistance

|

|

(Nanowerk News) Using a new 3D printing process, University of Nottingham researchers have discovered how to tailor-make artificial body parts and other medical devices with built-in functionality that offers better shape and durability, while cutting the risk of bacterial infection at the same time.

|

|

Study lead, Dr Yinfeng He, from the Centre for Additive Manufacturing, said: "Most mass-produced medical devices fail to completely meet the unique and complex needs of their users. Similarly, single-material 3D printing methods have design limitations that cannot produce a bespoke device with multiple biological or mechanical functions.

|

|

"But for the first time, using a computer-aided, multi-material 3D-print technique, we demonstrate it is possible to combine complex functions within one customised healthcare device to enhance patient wellbeing."

|

|

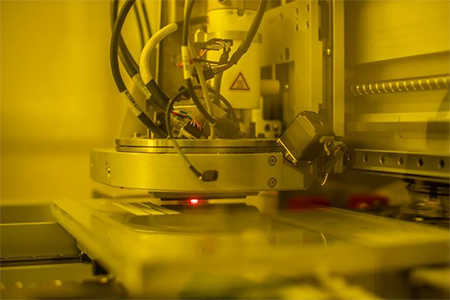

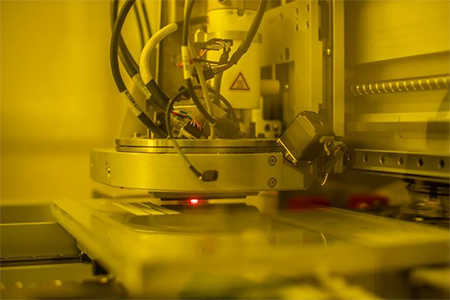

| Multi-Material 3D Printing Process. (Image: Centre for Additive Manufacturing (CfAM), University of Nottingham)

|

|

The hope is that the innovative design process can be applied to 3D-print any medical device that needs customisable shapes and functions. For example, the method could be adapted to create a highly-bespoke one-piece prosthetic limb or joint to replace a lost finger or leg that can fit the patient perfectly to improve their comfort and the prosthetic's durability; or to print customised pills containing multiple drugs - known as polypills - optimised to release into the body in a pre-designed therapeutic sequence.

|

|

Meanwhile, the aging population is increasing in the world, leading to a higher demand for medical devices in the future. Using this technique could improve the health and wellbeing of older people and ease the financial burden on the government.

|

How it works

|

|

For this study, the researchers applied a computer algorithm to design and manufacture - pixel by pixel - 3D-printed objects made up of two polymer materials of differing stiffness that also prevent the build-up of bacterial biofilm. By optimising the stiffness in this way, they successfully achieved custom-shaped and -sized parts that offer the required flexibility and strength.

|

|

Current artificial finger joint replacements, for example, use both silicone and metal parts that offer the wearer a standardised level of dexterity, while still being rigid enough to implant into bone. However, as a demonstrator for the study, the team were able to 3D-print a finger joint offering these dual requirements in one device, while also being able to customise its size and strength to meet individual patient requirements.

|

|

Excitingly, with an added level of design control, the team were able to perform their new style of 3D-printing with multi-materials that are intrinsically bacteria-resistant and bio-functional, allowing them to be implanted and combat infection (which can occur during and after surgery) without the use of added antibiotic drugs.

|

|

The team also used a new high-resolution characterisation technique (3D orbitSIMS) to 3D-map the chemistry of the print structures and to test the bonding between them throughout the part. This identified that - at very small scales - the two materials were intermingling at their interfaces; a sign of good bonding which means better device is less likely to break.

|

|

The study was carried out by the Centre for Additive Manufacturing (CfAM) and funded by the Engineering and Physical Sciences Research Council. The complete findings are published in Advanced Science ("Exploiting generative design for 3D printing of bacterial biofilm resistant composite devices").

|

|

Prior to commercialising the technique, the researchers plan to broaden its potential uses by testing it on more advanced materials with extra functionalities such as controlling immune responses and promoting stem cell attachment.

|