| Mar 27, 2023 |

New 3D metal printing technology using welding techniques

|

|

(Nanowerk News) A research team led by Dr. Sang-woo Song, Dr. Chan-kyu Kim, and Dr. Kang-myung Seo at the Department of Joining Technology of the Korea Institute of Materials Science (KIMS), a government-funded research institute under the Ministry of Science and ICT, has developed a foundational technology to control the volume of molten metal in the 3D metal printing process using welding techniques. They collaborated with research teams led by Professor Young-tae Cho and Professor Seok Kim of the Department of Mechanical Engineering at Changwon National University, and Dr. Dae-won Cho of the Busan Machinery Research Center at the Korea Institute of Machinery & Materials. Consequently, they successfully developed a metal 3D printing pen technology that enables continuous printing of metal in three-dimensional space with flexibility.

|

|

The team reported their findings in Advanced Science ("High-Throughput Metal 3D Printing Pen Enabled by a Continuous Molten Droplet Transfer").

|

|

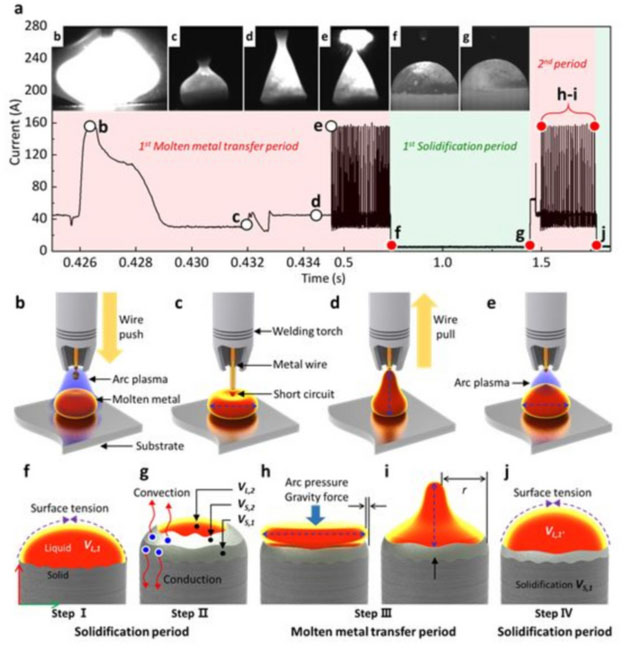

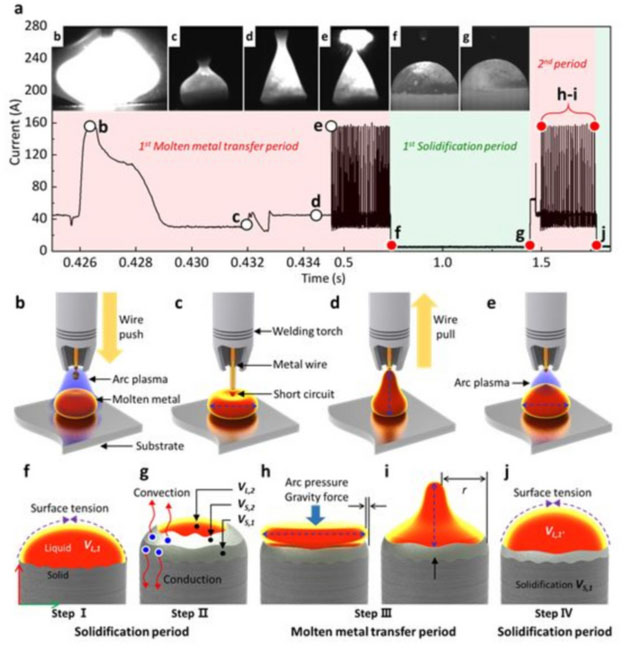

| Conceptual diagram of 3D printing mechanism. (Image: Korea Institute of Materials Science)

|

|

The metal 3D printing pen technology developed by the research team has the advantage of allowing free and continuous metal printing in any direction in 3D space, following the movement of the welding torch. Compared to conventional metal 3D printing using lasers, the equipment construction cost is lower, and additive manufacturing can be performed more quickly using commercially available welding materials, making it more economical.

|

|

Metal additive manufacturing using welding techniques has limitations in creating complex structures because it is a restricted process of building one layer at a time. Subsequent layers are laminated only after complete solidification, preventing the molten metal from flowing down. This results in a disadvantage in which cooling time is required and the conditions for lamination are limited to specific instances.

|

|

To address this issue, the research team conducted computer analysis to calculate and precisely control the surface tension of the molten metal and the solidified volume according to convection/conduction. They also developed a technology that enables metal additive manufacturing in all conditions, including horizontal, vertical, inclined, and overhead positions. By continuously laminating metal in the liquid phase before it fully solidifies, the manufacturing time is reduced, there are no boundaries between layers, and a dense microstructure with excellent mechanical properties is formed.

|

|

In terms of ductility, there is a 24.5% improvement compared to the existing Wire Arc Additive Manufacturing (WAAM) process, based on Inconel 625.

|

|

As of 2021, the domestic and global 3D printer markets are valued at KRW 82.1 billion and USD 2.1 billion, respectively, with annual average growth rates of 10.5% and 20%. This research achievement is expected to invigorate the manufacturing industry by establishing technological superiority in the field of metal additive manufacturing and producing high-value-added machines and components using it.

|

|

Dr. Sang-woo Song, the principal researcher at KIMS who led the research, said, "We added 3D free-form additive manufacturing to the continuous additive manufacturing process, which was considered impossible in the existing metal additive manufacturing process." He continued, "Like the existing 3D printing technology using polymers, it is now possible to easily manufacture complex structures using existing metal welding materials, suggesting a new paradigm for the manufacturing industry."

|

|

Currently, the research team is continuing follow-up research for additive manufacturing of high-value-added machinery and components in the nuclear power plant and defense industries.

|