| Sep 22, 2023 |

Engineers develop 3D-printed material with potential for more lifelike wearables

|

|

(Nanowerk News) Engineers and chemists at Lawrence Livermore National Laboratory (LLNL) and Meta have developed a new kind of 3D-printed material capable of replicating characteristics of biological tissue, an advancement that could impact the future of “augmented humanity.”

|

|

In a paper published in the journal Matter ("One-pot ternary sequential reactions for photopatterned gradient multimaterials"), LLNL and Meta researchers describe a framework for creating a “one-pot” 3D-printable resin in which light is used to pattern smooth gradients in stiffness to approximate gradients found in biology, such as where bone meets muscle. The framework addresses a key challenge in developing more lifelike wearables: “mechanical mismatch.” Whereas natural tissues are soft, electronic devices are usually made of rigid materials and it can be difficult and time-consuming to assemble such devices using traditional means.

|

|

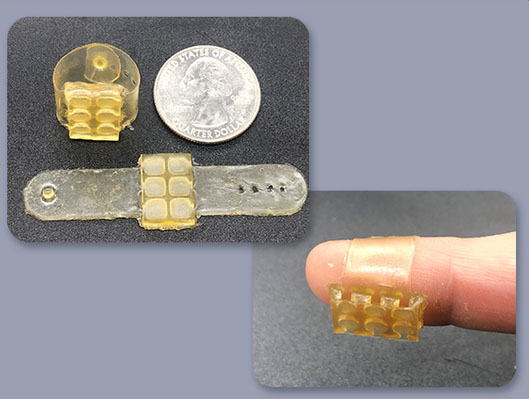

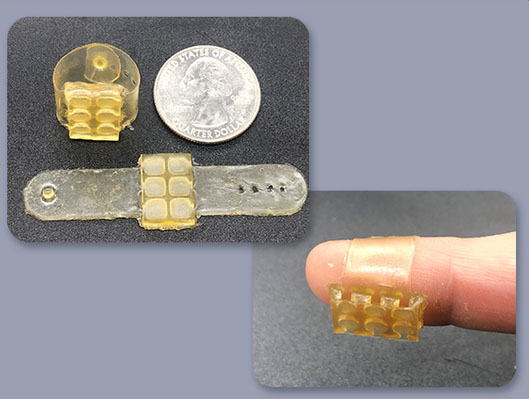

| The team demonstrated the material by developing a 3D-printed wearable braille device worn on the finger that can “translate” text messages to braille on-the-fly by filling the device with air at strategic points. (Image: Lawrence Livermore National Laboratory)

|

|

“For engineers, it’s very hard to get a softer material combined with a stiffer material such as is common in nature,” explained lead author and LLNL engineer Sijia Huang. “Engineers make a part that is stiff and another part that is soft, and then manually assemble them together, so we have a very sharp interface that compromises the mechanical property. This work has been looking into whether we can design continuous mechanical gradients from soft to stiff in a single resin system. Here, we're printing everything we're seeing, just using the light dosage to control the modulus.”

|

|

Huang said the technique works by manipulating the intensity of light applied to a photopolymer resin though the Digital Light Processing 3D printing process — a layer-by-layer technique that can rapidly produce parts by projecting light into a liquid resin — to modulate the deposited plastic material. A lower light intensity results in a softer material, while a higher light intensity results in a stiffer material.

|

|

To demonstrate the potential, engineers at Meta used the material to 3D-print an inexpensive braille display that could be worn on a single finger and connected to a smartphone and an air pump. When text is transmitted via the phone, sections of the wearable fill with air, causing it to deform and create braille letters, enabling a sightless person to “read” the text through the device. To allow the device to function, researchers needed to vary the stiffness in a single device so it would deform differently when air is pumped into the device, Huang said.

|

|

Huang, a Lawrence Postdoctoral Fellow in LLNL’s Materials Engineering Division, began the project as an intern at Meta’s Reality Labs in 2019, with a goal of creating wearable devices from a material that could vary in modulus but could be created in a single part. She worked on it prior to attending graduate school, and after getting a job at LLNL through the Lawrence fellowship, she discovered her old manager at Meta, paper co-author Thomas Wallin, had started a collaboration with LLNL. Serendipitously, Huang was able to finish the project at the Lab.

|

|

“A beautiful feature of additive manufacturing is that we can create these impossible structures, but also we are somewhat limited in terms of the material properties — we only have a certain amount of material that we can pick from,” Huang said. “One of the initial motivations was, ‘what if we could have the same resin system and replicate the engineered plastic systems effortlessly by merely adjusting the light intensity?’ That would save a significant amount of time and effort for engineers, particularly when incorporating new properties of materials.”

|

|

The material is stretchable to around 200 times its original properties, and as its gradient transitions from soft to stiffer material, its toughness increases by 10 times. Huang said the material could be tailored for energy-absorbing materials, soft robotics and wearable electronic devices.

|

|

“One of the requirements that we want to look at for wearable devices is the necessity for a consistently stable material over the long term,” Huang said. “What sets this work apart is our demonstration of the material’s stability under light and ambient conditions; we actually expose our materials under the ultraviolet (UV) light to observe their behavior over extended exposure periods. Using UV curing techniques tends to decrease the mechanical gradients over time, so this shows how stable our material is.”

|

|

“This development is important because plastics generally struggle to maintain performance over long periods of years to decades, compared to some other materials like metals. For 3D-printed plastics, this is even more of a challenge, even when impossible exquisite geometries can be printed,” said co-author Maxim Shusteff, a group leader in the Materials Engineering Division. “This paper describes a significant advance for variable-stiffness polymer materials with long-term stability. These results advance LLNL’s mission focus of discovering and developing new paths forward in both manufacturing methods and their associated materials.”

|