| Oct 12, 2023 |

Concrete as CO2 trap - right at the plant

|

|

(Nanowerk News) After their production, which emits a lot of carbon dioxide, cement-based building materials such as concrete absorb the climate gas again – a process that takes decades and can hardly be controlled. What if it could be accelerated to protect the climate? Empa researchers are collaborating with numerous partners in an elaborate project to find a solution that already takes place in the concrete production plant. Initial results are encouraging.

|

Key Takeaways

|

|

Cement-based materials like concrete, after their initial high CO2 emitting production, reabsorb some of the emitted climate gas, a process named "Carbonation".

Empa researchers, in collaboration with partners, are working on the DemoUpCARMA project, aiming to accelerate carbonation in concrete plants.

Experiments in a specially installed plant utilized CO2 from a wastewater treatment plant and recycled concrete materials to test carbon uptake.

CO2-enriched recycled concrete demonstrated higher strength and absorbed up to 10% of emissions from the original cement production.

Initial life cycle analyses suggest CO2-enriched recycled concrete could decrease greenhouse gas effects by around 13% compared to traditional concrete.

|

The Research

|

|

Even the biggest sinners can improve: This is also the hope of experts when it comes to the "climate sinner "concrete. 6 to 8 percent of man-made CO2 emissions worldwide are attributable to cement, the indispensable binder for the hard and versatile building material – but at the same time it is able to chemically bind the climate gas emitted during cement production again after manufacture; at least partially: between 11 and 30 percent, depending on the recipe and conditions.

|

|

"Carbonation" is the name given to this process, in which limestone is formed from calcium hydroxide in concrete and CO2 – a leisurely reaction that takes years and whose pace depends on numerous factors. For a long time, experts have been thinking about using it to improve the carbon footprint of concrete – and now, in the DemoUpCARMA project, Empa experts are working with partners under the leadership of ETH Zurich to test whether and how the process can be used and, above all, accelerated in a real concrete plant.

|

Elaborate analyses in the Empa laboratories

|

|

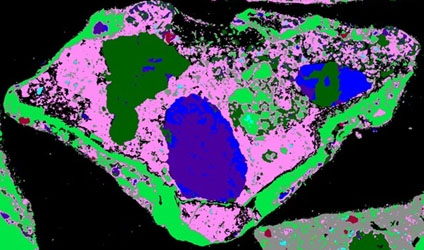

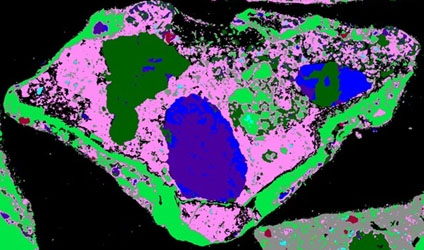

| Recycled granulate particles (Ø about 1.5 mm) after carbonation: The main products are CaCO3 (light green) and C-S-H (pink), which reacts with newly formed cement phases during the production of recycled concrete. (Image: Empa)

|

|

Specifically: in a specially installed plant of the company Kästli Bau AG in Rubigen in the canton of Bern – and with recycled material from deconstructed concrete structures. The carbon dioxide with which this material is "fed" comes from the nearby wastewater treatment plant and is delivered in a liquefied state. At the plant, it is then stored in a special silo from where the recycled granules are continuously "flooded" using a process developed by the Bern-based company neustark AG – in other words, exposed to pure CO2 gas and the uptake precisely measured. The team of experts researched the processes that take place in detail during the CO2 uptake of the recycling granulate. They also investigated how so-called "recycling water" from water, cement and sand, which is produced for example during the cleaning of concrete vehicles and mixing plants, can be used to bind carbon dioxide.

|

|

Andreas Leemann and Frank Winnefeld from Empa's Concrete & Asphalt lab conducted numerous tests to determine how well and efficiently the recycled granulate absorbs CO2 and under what conditions – with surprising results. Samples of the treated material showed clear changes under the microscope: Smaller particles had patches of dark and light portions on the surface, where the original cement stone had changed.

|

|

Analysis with a scanning electron microscope showed that the light portions were calcium carbonate, while the dark phases consisted mainly of calcium silicate hydrate – C-S-H for short – the main product of cement hydration that gives concrete its strength. This C-S-H has been deprived of part of its calcium by carbonation: It is thus lower in calcium and can in turn react with newly formed cement compounds in recycled concrete – with the result that its compressive strength increases.

|

|

Practical tests with various types of concrete frequently used in Switzerland confirmed these insights. The recycled products with carbonated concrete granules achieved higher strengths than comparative concretes with untreated recycled material. "So a reactive phase that is newly formed in the granules and produces higher strength in the recycled concrete," Leemann says, "that did surprise us indeed."

|

|

Moreover, the analyses showed that moisture plays an important role in CO2 accumulation: Drier recycled mixes showed significantly faster uptake of the greenhouse gas than material that was overly moist. And because the outdoor storage of recycling granulates in Switzerland does not exactly promote drying, the Empa experts ask whether this process should be technically optimized.

|

Significant improvement within reach

|

|

The positive results show that the process can make concrete more climate-friendly in two ways. Firstly, by absorbing CO2 to "relieve" the atmosphere: Up to 10 percent of the emissions that were released into the atmosphere during the production of the cement for the original concrete can be absorbed by the novel building materials.

|

|

Secondly, by reducing the cement content in recycled concrete – by 5 to 7 percent – thanks to its higher strength. The bottom line, according to the Empa experts, is that the potential for CO2 savings are a good 15 percent.

|

|

And: CO2 treatment of the "recycling water" showed further potential. Samples were able to bind a considerable amount of the gas in analyses: about 120 grams per kilogram of dried material. The use of this material also led to an increase, albeit small, in the strength of the concrete to which it was added.

|

|

The extent to which these results can be implemented in practice is, of course, still an open question. For example, the question of how well and at what technical and financial expense the process can be implemented in concrete plants. And how the carbonation of recycled granules will affect different concretes in the long term, i.e. over the entire service life of several decades.

|

Great potential over the entire life cycle

|

|

An initial assessment of this is provided by so-called life cycle analyses by Romain Sacchi and Christian Bauer of the Technology Assessment Group at the Paul Scherrer Institute (PSI) in Villigen, together with Empa expert Andreas Leemann. Taking into account all influences on CO2 emissions from production, use to disposal of "classic" concretes as well as variants with untreated and with CO2-enriched recycled granulate, the study shows that the carbonated material can reduce the net greenhouse gas effect by around 13 percent – compared to concrete with conventional cement and without recycled material. For concrete with recycled material, the effect is still 9 percent; a significant potential.

|