| Nov 09, 2023 |

The secret to longer lasting batteries might be in how soap works

|

|

(Nanowerk News) When it comes to making batteries that last longer, a team of researchers including engineers at Brown University and Idaho National Laboratory believes the key might be in how things get clean — specifically how soap works in this process.

|

|

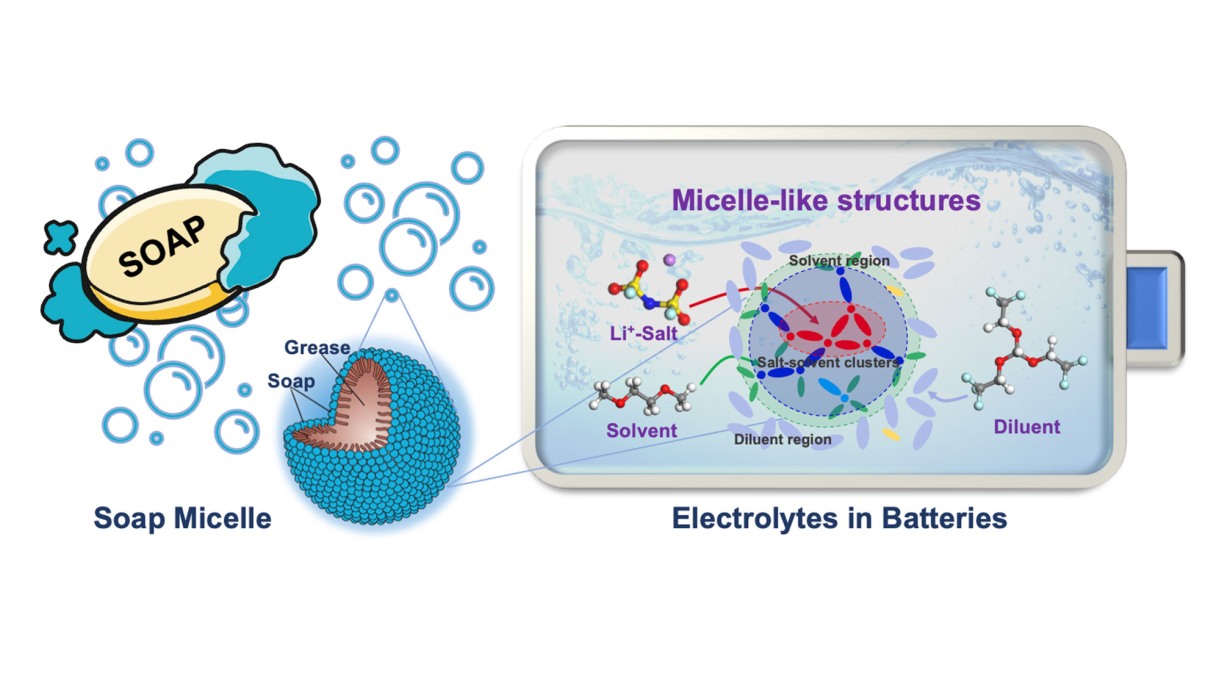

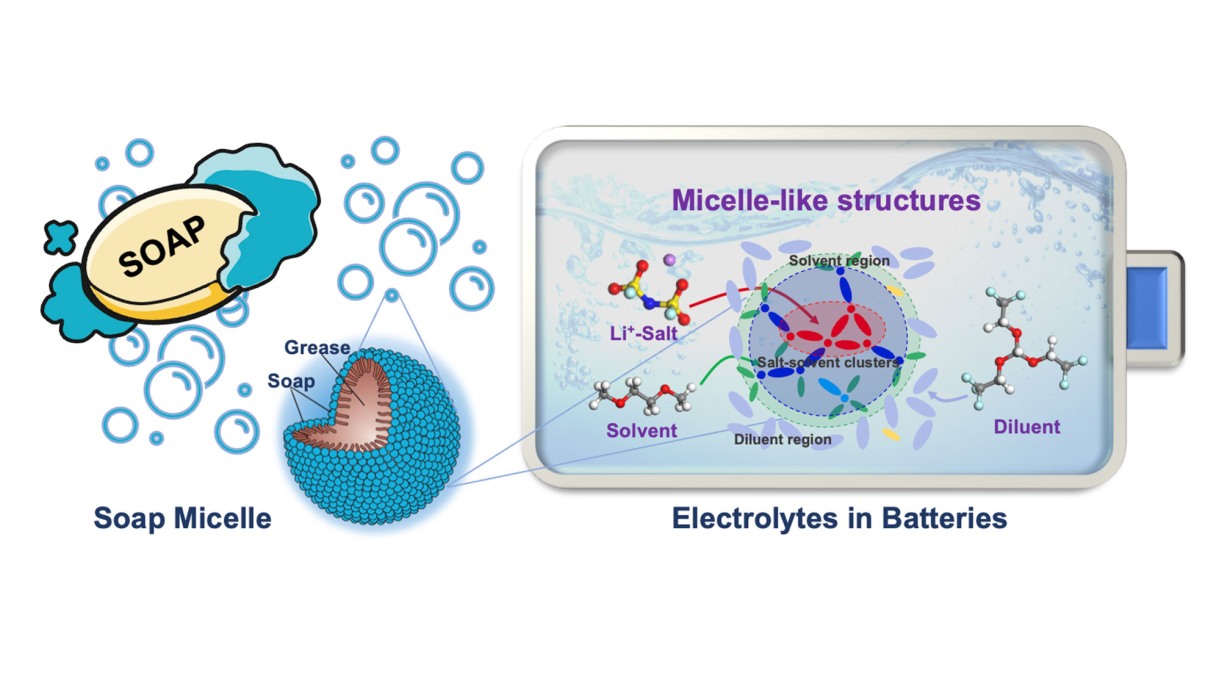

Take handwashing, for instance. When someone washes their hands with soap, the soap forms structures called micelles that trap and remove grease, dirt and germs when flushed with water. The soap does this because it acts as bridge between the water and what is being cleaned away, by binding them and wrapping them into those micelle structures.

|

Key Takeaways |

|

Research indicates that soap-like structures within new electrolytes could enhance battery life and energy storage.

Localized high-concentration electrolytes show promise for better performance in lithium metal batteries compared to traditional ones.

Understanding micelle formation in electrolytes offers a new approach to optimizing the balance of ingredients for improved battery design.

Idaho National Laboratory's implementation of the new theory demonstrates potential for extending lithium metal battery life.

The research provides a unified theory that could resolve the electrolyte design bottleneck in creating high-density batteries.

|

|

| Researchers show that one of the most promising substances for designing longer lasting lithium batteries form micelle-like structures like they do in soap. (Image: Yue Qi)

|

The Research |

|

In conducting a new study published in Nature Materials ("Localized high-concentration electrolytes get more localized through micelle-like structures"), researchers noticed that a similar process plays out in what has become one of the most promising substances for designing longer lasting lithium batteries — a new type of electrolyte called a localized high-concentration electrolyte. This new understanding of how this process works, they posit in the paper, might be the missing piece to fully kicking the door open in this emerging sector of technology.

|

|

“The big picture is that we want to improve and increase the energy density for batteries, meaning how much energy they store per cycle and how many cycles the battery lasts,” said Yue Qi, a professor at Brown’s School of Engineering. “To do this, materials inside of traditional batteries need to be replaced to make long-life batteries that store more energy a reality — think batteries that can power a phone for a week or more, or electric vehicles that go for 500 miles.”

|

|

Scientists have been actively working to transition to batteries made from lithium metal because they have a much higher energy storage capacity than today’s lithium-ion batteries. The holdup is traditional electrolytes, which are integral because they allow an electrical charge to pass between a battery’s two terminals, sparking the electrochemical reaction needed to convert stored chemical energy to electric energy. Traditional electrolytes for lithium-ion batteries, which are essentially made of low-concentration salt dissolved in a liquid solvent, don’t do this effectively in metal-based batteries.

|

|

Localized high-concentration electrolytes were engineered by scientists at Idaho National Laboratory and Pacific Northwest National Laboratory to address this challenge. They are made by mixing high concentrations of salt in solvent with another liquid called a diluent, which makes the electrolyte flow better so that the power of the battery can be maintained.

|

|

So far, in lab tests, this new type of electrolyte has shown promising results, but how it works and why has never been fully understood — putting a cap on how effective it can be and how it can be better developed. This is what the new study helps to address.

|

|

“The paper provides a unified theory to why this electrolyte works better and the key understanding of it came by finding that micelle-like structures form within this electrolyte — like they do with soap,” said Bin Li, a senior scientist at Oak Ridge National Laboratory who worked on the study. “Here we see that the role of the soap or surfactant is played by the solvent that binds both the diluent and the salt, wrapping itself around the higher concentration salt in the center of the micelle.”

|

|

By understanding this, the researchers were able to break down the ratios and concentrations needed to bring about the optimal reactions for the batteries. This should help solve one of the main trouble points in engineering this electrolyte, which is finding the proper balance for the three ingredients. In fact, the work not only provides better guidelines for making localized high-concentration electrolytes that function, but for making ones that work even more effectively.

|

|

Researchers at Idaho National Laboratory put the theory into action. Doing so, they found the theory, so far, holds up and helps to extend the life of lithium metal batteries. The team is excited to see what designs for localized high-concentration electrolytes come from their work but know significant progress remains to overcome the electrolyte design bottleneck for high-density batteries. Right now, they are amused that the secret may have been in something as mundane and everyday as soap.

|

|

“The concept of the micelle may be new for the electrolyte, but it’s actually very common for our daily life,” Qi said. “Now we have a theory, and we have guidelines to get interactions we want from the salt, the solvent and the diluent in the electrolyte, and what concentration they have to be at and how you mix them.”

|