| Jun 20, 2012 |

Graphene? From any lab!

|

|

(Nanowerk News) Considered by many as the most promising material of the future, graphene still remains an expensive and hard-to-fabricate substance. Researchers from the Institute of Physical Chemistry of the Polish Academy of Sciences in Warsaw, and the Interdisciplinary Research Institute in Lille developed a low cost method for manufacturing multilayered graphene sheets. The new method does not require any specialized equipment and can be implemented in any laboratory.

|

|

A low cost method for producing graphene sheets has been developed in cooperation within research project by teams from the Institute of Physical Chemistry of the Polish Academy of Sciences (IPC PAS) in Warsaw and the Interdisciplinary Research Institute (IRI) in Lille, France. The method is simple enough to be provided in almost any laboratory throughout the world.

|

|

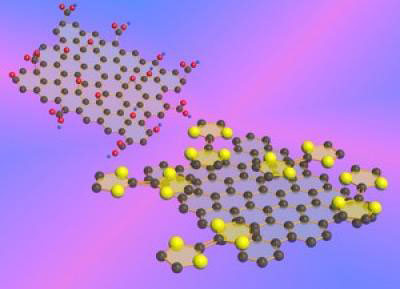

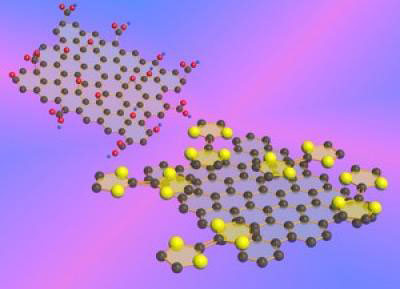

| This is a visualization of a graphene oxide sheet (left top) and a graphene surface with attached tertathiafulvalene (TTF) molecules (right bottom). Graphene rings are composed of six carbon atoms, TTF rings – of three carbon and two sulphur atoms. (Image: IPC PAS, Piotr Gdziorowski)

|

|

Graphene was discovered in 2004, by peeling off carbon layers from graphite using an ordinary scotch tape. "In what had been peeled off the researchers were able to find one-atom-thick sheets. And that was graphene. If we are thinking about industrial applications of graphene, we have to find better controlled methods for producing this material in a large scale, without using an expensive, specialized equipment", says Izabela Kaminska, a PhD student from the IPC PAS, a scholarship holder of the Foundation for Polish Science within the International PhD Projects Programme. Kaminska has carried out her experiments at the International Research Institute.

|

|

Considering the structure, graphene is a two dimensional system composed of six-membered carbon rings. The hexagonal graphene lattice resembles a honeycomb, with the difference that the graphene sheet has the lowest possible thickness: of one atom only.

|

|

Unusual properties of graphene are closely related to the unique structure. Graphene is almost entirely transparent, more than hundred times stronger than steel and very flexible. At the same time it shows excellent thermal and electric conductivity, which makes it a good material for applications in electronics, e.g. for manufacturing thin, flexible and strong displays or fast processing circuits. It is also suitable as a material for various sensors.

|

|

The existing methods for fabricating graphene – including deposition of epitaxial layer on a metallic substrate or silicon carbide, or chemical or physical vapour deposition – require expensive, specialized equipment and complex manufacturing procedures. Meanwhile, the only more complex apparatus used in the method for producing graphene sheets developed at the IPC PAS and the IRI is an ultrasonic cleaner, an equipment common in many laboratories.

|

|

The new process for producing graphene sheets starts with graphite, one of carbon allotrope, on the molecular level resembling a sandwich composed of many graphene planes. These sheets are hardly separable. To weaken interactions between them, graphite must be oxidized, which is usually accomplished with the Hummers method. A powder obtained in that way – graphite oxide – is subsequently suspended in water and placed in an ultrasonic cleaner. The ultrasounds exfoliate oxidized graphene sheets from each other and the resulting colloid contains single graphene oxide flakes with diameter of about 300 nanometers.

|

|

The researchers from the IPC PAS and the IRI used graphene oxide manufactured at Materials Science Division in North East Institute of Science and Technology (NEIST) in Dispur, India. "One-atom-thick graphene oxide colloids were a good starting material, but numerous oxygen-containing functional groups became a real difficulty. The problem was that they changed dramatically the physico-chemical properties of the material. Instead of an excellent conductor we had... an insulator", explains Kaminska.

|

|

To remove oxygen from graphene flakes, the researchers from the IPC PAS and the IRI decided to use non-covalent pi-pi stacking interactions between the carbon rings of graphene oxide and the aromatic rings of a compound called tertathiafulvalene (TTF). A TTF molecule is composed of two rings containing three carbon and two sulphur atoms each. "Practically, it was sufficient to mix graphene oxide with tertathiafulvalene, and then put the whole in an ultrasonic cleaner. The interactions between the TTF rings and the graphene oxide rings resulted in a reduction of graphene oxide to graphene with a simultaneous oxidation of the TTF molecules", describes Kaminska.

|

|

As a result, the obtained composite contained graphene flakes with TTF molecules intercalated into them. A droplet of the composite solution was subsequently deposited onto an electrode and dried. Graphene flakes formed on the surface a smooth coating with controllable thickness from 100 to 500 nm that was composed of a few dozen to a few hundreds alternate graphene sheets and TTF molecules.

|

|

The final stage in the production of graphene coating was to expel tertathiafulvalene molecules, which was attained by a simple chemical reaction with an appropriately selected compound.

|

|

"One of our motivations for the research was to look for new methods for detecting biological substances. That's why after expelling TTF from the graphene coating we checked immediately if we could reincorporate the chemical into the matrix. It turned out that yes. Therefore it is possible to develop a process allowing one to bind a selected compound to a TTF molecule, and then to incorporate the entire complex into a graphene sheet on an electrode and monitor the electric current flow", sums up Prof. Marcin Opallo (IPC PAS).

|

|

A publication describing the new method appeared early this year in the prestigious journal Chemical Communications, with the cover showing computer visualisation of the graphene sheets with TTF ("Preparation of graphene/tetrathiafulvalene nanocomposite switchable surfaces"). At present, the researchers from the IPC PAS and the IRI continue their work on further decrease of graphene matrix thickness. The final stage reached also the experiments which show that it is possible to incorporate into the graphene sheet TTF molecules with attached mannose (one of the monosaccharides).

|