| Mar 21, 2013 |

Portable fuel cell system with nanostructured electrodes

|

|

(Nanowerk News) Researchers from the Functional Integration Group, the Advanced Manufacturing Research Institute of the National Institute of Advanced Industrial Science and Technology (AIST) in Japan, have developed a handy, portable fuel cell system.

|

|

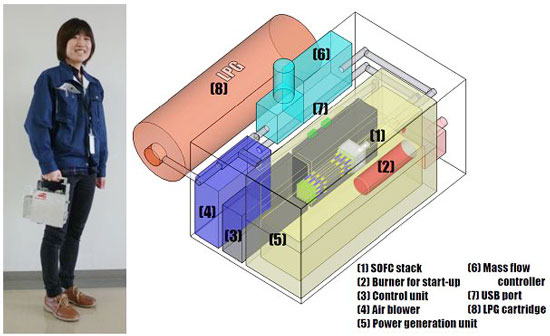

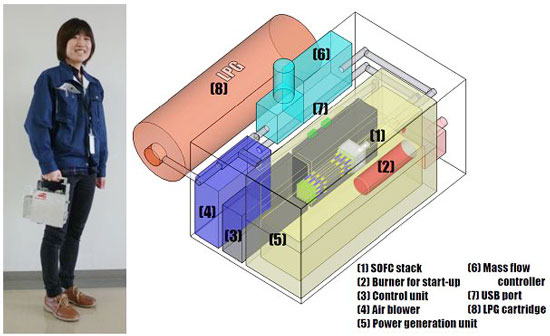

While the developed system employs microtubular solid oxide fuel cells (microtubular SOFCs), a nanostructure-controlled electrode has enabled the direct use of highly portable general-purpose hydrocarbon fuels, including liquefied petroleum gas (LPG). The rapid start-up and portability of the system mean that it is expected to find application as a power source in emergency and disaster situations and for outdoor use.

|

|

This technology was exhibited at the AIST booth at nano tech 2013, the 12th International Nanotechnology Exhibition and Conference, to be held from January 30 to February 1 at Tokyo Big Sight (Koto-ku, Tokyo).

|

|

| Photo and schematic diagram of the portable fuel cell system.

|

|

Social Background of Research

|

|

SOFC is expected to have the highest power generation efficiency among fuel cells, and at present efforts are being made to put SOFC to practical use as stationary power sources. SOFC is also expected to be applied to power sources for next-generation vehicles and to portable power sources, but the high operating temperature (700 - 1,000°C) of conventional SOFCs make the realization of such practical use difficult due to the impossibility of rapid start-up.

|

|

However, the recent proliferation of small electronic devices such as smartphones, One-Seg TVs, and video cameras, demands power sources of several watts to several tens of watts able to start up rapidly in disaster and emergency situations and for outdoor use, when it is difficult to access commercial power sources and quick chargers. In addition, it is difficult to obtain hydrogen at present, and therefore practical SOFCs able to generate power using general-purpose hydrocarbon fuels such as LPG cartridges are awaited.

|

|

History of Research

|

|

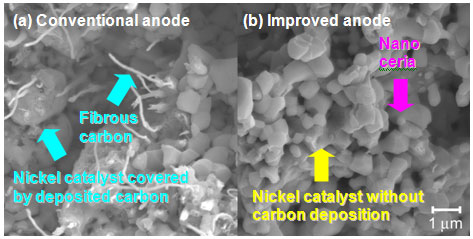

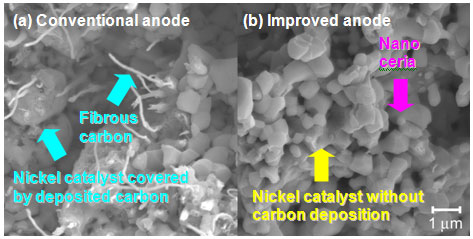

In the Advanced Ceramic Reactor Project (FY2005 - 2009) supported by the New Energy and Industrial Technology Development Organization, AIST developed a microtubular SOFC with a low operating temperature of around 600°C, and demonstrated 50 - 200-watt generator SOFC modules using hydrogen fuel can be started up within several minutes. AIST also demonstrated that the addition of a ceria (CeO2)-based catalyst layer (nano ceria) to an electrode made it possible to generate power by means of the internal reforming of methane fuel at the low temperature of 450°C.

|

|

The present development is a result of AIST’s efforts to develop a fuel cell system able to start up rapidly using hydrocarbon fuels such as LPG, which are more readily available and easily transportable than hydrogen or methane.

|

|

Details of Research

|

|

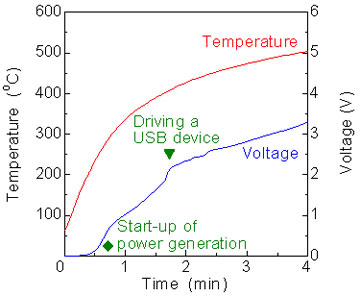

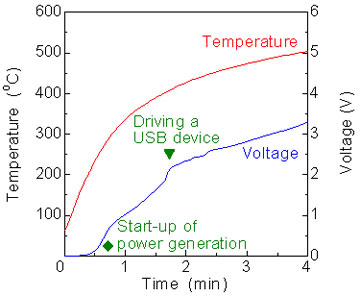

Butane, one of the main constituents of LPG, is more prone than methane to carbon deposition as a result of thermal decomposition, and rapidly accelerate the degradation of the fuel electrode (the anode), when supplied directly to fuel cells. Because of this, in conventional fuel cell systems, it is necessary to reform the butane fuel using external reformers, which employ expensive noble metal catalysts, before it is supplied to the fuel cells. In the present study, a nanostructure-controlled electrode with higher durability than that of conventional electrodes was developed by applying nano ceria, which possesses an internal reforming function, to the substrate material of the anode. The use of this anode in the newly developed microtubular SOFC system makes it possible to generate power stably even when butane fuel is directly supplied to the system. In addition, the increased durability enables rapid start-up using the exhaust gas from an LPG burner, which is used only at start-up. As a result, the developed fuel cell is able to reach 400°C and drive a USB device within two minutes, approximately half the time required by conventional microtubular SOFCs (Fig. 1). Since the nanostructure-controlled electrode has a sufficient internal reforming function, it will contribute to the reduction in the size and the cost of fuel cell systems by eliminating the use of an external reformer.

|

|

| Figure 1: Rapid start-up operation with direct butane utilization (when a USB device is connected).

|

|

Figure 2 shows scanning electron microscope (SEM) images of anodes after direct LPG power generation. In the case of the conventional anode, (a), which became incapable of power generation within a period of several hours, the nickel catalyst contained in the anode was covered by deposited carbon, and the growth of fibrous carbon was also observed. By contrast, even after power generation for 24 hours, no carbon deposition was observed in the case of the improved anode with nano ceria, (b), indicating a marked increase in durability against the direct butane utilization.

|

|

| Figure 2: SEM images of a conventional anode (a), and an improved anode (b) after direct butane power generation.

|

|

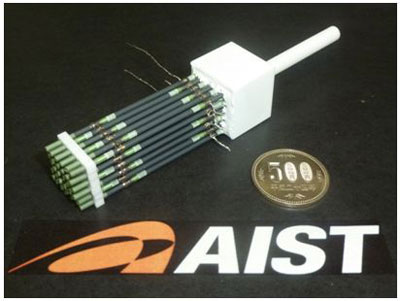

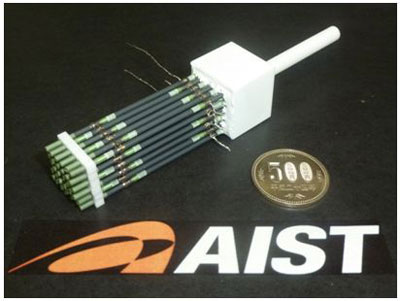

Using a DC 5 - 36 volt microtubular SOFC module employing the developed nanostructure-controlled anodes as substrates (Fig. 3), a prototype handy fuel cell system using LPG cartridges as fuel was manufactured. The system was able to drive a DC 5 volt USB device within two minutes (Fig. 4). In addition, because only an LPG burner is used for start-up, no external power source is necessary. This development has shown the potential of SOFC generation systems as power sources in disaster and emergency situations, for outdoor use, and for next-generation vehicles.

|

|

| Figure 3: Microtubular SOFC module (DC 5 - 36 volts).

|

|

| Figure 4: Driving test of USB device (LED light) using LPG cartridge fuel. In principle, 24-hour continuous operation per cartridge is possible.

|

|

Future Plans

|

|

In addition to improving the power generation performance and durability of the SOFC module, efforts will focus on the development of handy fuel cell systems incorporating fuel reforming and fuel supply control units, and their application as power sources in disaster and emergency situations, for outdoor use, and for next-generation vehicles.

|