| Jan 18, 2024 | |

Self-assembling robotic structures with mechanical metamaterials for autonomous construction (w/video) |

|

| (Nanowerk News) Imagine intelligent infrastructure that automatically self-assembles, reshapes and repairs itself on demand. Buildings that organically grow new rooms when needed, self-optimizing their layout forever. Bridges that strengthen or elongate past obstacles without human intervention. And colonies on Mars constructed from local materials without astronaut extravehicular activity. | |

| For a long time, this tantalizing vision of robotic programmable matter has seduced researchers, yet tangible progress toward these goals has remained perpetually just over the horizon despite intense interest. Technical barriers spanning fields from nanoscale manufacturing to autonomous robot coordination have denied would-be architects of future intelligent structures. Until now. | |

| Scientists from NASA’s Ames Research Center have demonstrated a modular robotic system that autonomously constructs meter-scale lattices with unprecedented strength and stiffness for self-assembling matter. By separating structure and actuation, the breakthrough design points toward robotic programmable matter finally transitioning from fanciful what-if concept to promising emerging reality. | |

| The findings have been published in Science Robotics ("Ultralight, strong, and self-reprogrammable mechanical metamaterials"). | |

|

|

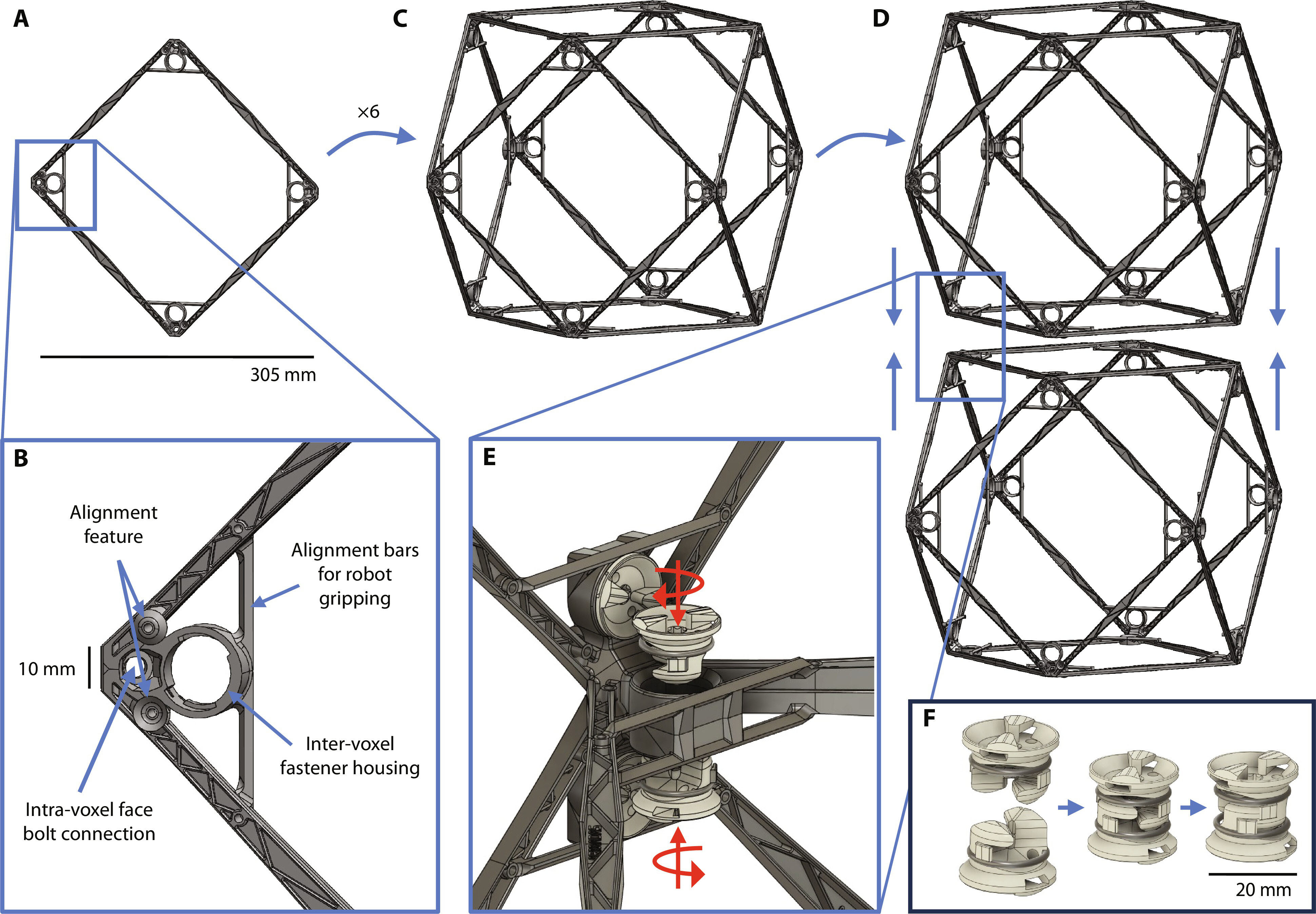

| Overview of the structural system. (A) Individual injection-molded faces have alignment features for inter-voxel connections and robotic gripping (B). Six faces are assembled into the cuboctahedron unit (C). These units are connected face to face (D) using four captive and reversible genderless fasteners (E and F). The bounding box of the resulting voxel building block is a cube with 304.8 mm side lengths. | |

| The new system combines lightweight polymer composite building blocks with simple autonomous robots to create large lattice structures with competitive strength and stiffness. This represents meaningful progress toward the demanding performance, throughput and scalability requirements of infrastructure and aerospace. | |

| Self-assembling structures have remained stuck at the small prototype scale despite intense R&D interest from academia, the military and companies like Ikea. Biology routinely constructs complex functional structures from discrete molecular building blocks, yet engineered self-assembly has proven enormously difficult. Early visionary proposals imagined future nano-scale systems constructing atomically precise products but faced intractable coordination and manufacturing barriers. | |

| Later pioneering work developed centimeter-scale magnetic robot modules that could locomote and connect to build arbitrary shapes. However, the weak magnetic forces limited strength and scalability. An alternative approach used small robotic arms to grasp and join larger blocks with stronger mechanical connectors. But the complex robots added substantial mass that diluted strength-to-weight ratio. These and other self-assembling platforms demonstrated key capabilities like autonomous construction, self-repair and reconfiguration after assembly. Yet until now, all fell short of realizing programmable matter’s full disruptive potential due to deficiencies in strength, stiffness, scale, cost or build rate. | |

| The new system achieves record structural performance for self-assembling matter by innovatively separating the structure and actuation components. Lego-like composite polymer voxels form the lightweight high-strength truss structure. Two types of simple robots then assemble and later reconfigure the voxels using the lattice geometry itself for precise positioning without external sensors. This clean division between chassis and locomotion reduces mass and increases reliability. | |

| Structurally, the voxels connect face-to-face in repeating diamond patterns to create an extremely lightweight cuboctahedron lattice material. Reversible genderless fasteners at each face interface allow the robots to securely link voxels with consistent precision and a 797N holding force. | |

| In compression tests, 3x3x3 voxel assemblies failed at loads over 9,000 Newtons. This equates to a very promising specific strength over 11 kPa at ultra-low densities around 0.01 g/cm3 – competitive with high-performance aerospace lattices. The researchers also measured stiffness between 1-2 MPa, which rivals commercial carbon fiber trusses on a strength/weight basis. Quantitative characterization confirms the assembled lattice metamaterial achieves mechanical properties applicable for demanding infrastructure, aerospace vehicles and space structures rather than just small demonstrations. And the discrete reversible connections enable future autonomous error correction impossible with conventional materials. | |

| This performance eclipses previous self-assembling smart material platforms by orders of magnitude. The best prior modular matter demonstrations managed under 100 kPa strength at far higher densities. Even conceptually similar but manually reconfigured lattice robots achieved only ~1/10th the strength at 5x the density of the new system. Quantitative comparisons confirm the current robotic lattices more conclusively escape the “toy problem” domain into useful macroscale performance. Yet unlike workshop-assembled architectures, in situ automated reconstruction enables applications tolerating no human presence while maximizing sustainability. | |

| On the robotics side, the team built two types of autonomous transport robots that collaborate to precisely place voxels. A larger four-legged “cargo” robot ferries new voxels from the supply depot to the construction site using a gripper arm. There, a simpler two-legged “crane” robot removes cubes from the cargo robot and positions them into the growing lattice structure using alignment guides. | |

| The crane robot can also disassemble voxels, enabling later reconfiguration for self-repair or properties changes. Once the crane positions new voxels, a small internal “fastening” robot squeezes through the lattice cavities to align and bolt the new and existing voxels together using genderless reversible mechanical fasteners. The simple wireless robots coordinate via relative positioning and dead reckoning rather than complex computer vision, reducing sensing requirements. | |

| The time-lapse video shows a simulated 256-voxel build of a large tower by three teams of robots, implementing the autonomous path planning algorithm. The three robots started the build on a seed structure consisting of five seed voxels. The robots started from their designated base positions, built the tower, and returned to their bases afterward. For clarity, each team is shown in a different color. (© Science Robotics) | |

| In one demonstration (see video above), the system autonomously assembled a meter-wide 256-voxel shelter structure with sloping walls highlighting overhang construction capability. The two transport robots traveled over 3km while completing 14,600+ manipulations with 99% success. The fastening robot successfully joined 596 voxels with 95.8% reliability. Total assembly spanned 4 days, for a very promising 20,000 cubic mm/sec build rate thanks to concurrent voxel transport. | |

| Demonstrated performance already meets requirements for aerospace applications like antenna dishes, towers and orbital truss structures. And unlike monolithic forms, the system’s discrete nature enables future autonomous error correction and repair. | |

| With further development, the researchers say this discrete lattice construction paradigm could form literal building blocks for affordable, resilient and sustainable next-generation infrastructure. Installation, maintenance, upgrades and recycling would become automated, flexible and waste-free. NASA aims to mature the technology for constructing extra-terrestrial outposts without astronaut EVA using local regolith resources. Terrestrial applications range from temporary shelters and expeditionary structures to adaptable architecture that fluidly evolves alongside human needs. More speculatively, self-assembling programmable matter promises a revolution in materials science if strengths and manufacturing scale continue improving. |

| Source: Nanowerk (Note: Content may be edited for style and length) |

We curated a list with the (what we think) 10 best robotics and AI podcasts – check them out!

Also check out our Smartworlder section with articles on smart tech, AI and more.