| Posted: Nov 16, 2006 | |

Antibacterial wallpaper through nanotechnology |

|

| (Nanowerk Spotlight) Zinc oxide (ZnO) is considered a workhorse of technological development exhibiting excellent electrical, optical, and chemical properties with a broad range of applications as semiconductors, in optical devices, piezoelectric devices, surface acoustic wave devices, sensors, transparent electrodes, solar cells, antibacterial activity etc. Thin films or nanoscale coating of ZnO nanoparticles on suitable substrates are viewed with great interest for their potential applications as substrates for functional coating, printing, UV inks, e-print, optical communication (security-papers), protection, barriers, portable energy, sensors, photocatalytic wallpaper with antibacterial activity etc. Various methods like chemical, thermal, spin coating, spray pyrolysis, pulsed laser deposition have been used for thin film formation but they are limited to solid supports such as metal, metal oxides, glass or other thermally stable substrates. Coating of ZnO nanoparticles on thermolabile surfaces is scarce and coating on paper was yet to be reported. Paper as a substrate is an economic alternative for technological applications having desired portability and flexibility. Researchers from the National Tsing Hua University in Taiwan found a way of coating paper with ZnO nanoparticles using ultrasound. | |

| Professor Yong-Chien Ling, who led the research team, explained the recent findings to Nanowerk: "Our work presents for the first time a simple, green, and cost-effective way of coating ZnO nanoparticles on a paper surface (thermolabile substrate) without the use of binders." | |

|

|

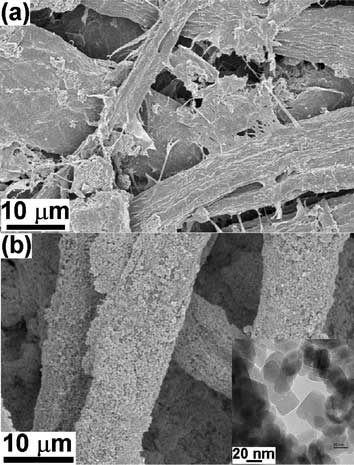

| SEM images of (a) blank paper and (b) ZnO nanoparticles coated paper obtained after 10 min of sonication. Inset is the TEM image of the ZnO nanoparticles used in this work. (Reproduced by permission of The Royal Society of Chemistry) | |

| Existing coating techniques for paper, especially the contact mechanical ones, can cause surface defects, variable layer thickness and composition, consume more material by filling fiber interstices and need excess solvent and energy. Therefore non-impact, spray-based techniques are generally preferred but they are costly, require more maintenance and consume even more solvent medium. | |

| Coating on the nanoscale would enable improved techniques that consume less material. Furthermore, with increased emphasis on green chemistry, interest has been developed towards adoption and implementation of sustainable processes by minimizing the use of toxic chemicals, solvents, and energy. | |

| "This led us to conclude that development of a nonimpact coating technique on the verge of green chemistry and nanoscience is crucial for revitalizing coating progress through nanostructuring" says Ling. | |

| Using ultrasound as a coating method is simpler than mechanical methods. It is also cheaper, uses less material, avoids waste and uses water as the solvent. Unlike dip coating, ultrasound coating enables coating of ZnO nanoparticles only on one side of the paper, thereby reducing the amount of ZnO nanoparticles required. It also prevents the ZnO nanoparticles being filled in the interstitial voids unlike mechanical blades, bench coaters or spray techniques. | |

| It is well known that purity of ZnO is important for its application, demanding extreme thermal treatment after its synthesis or coating. This is with the intension of reducing or eliminating the organic species adsorbed on the surface of ZnO, which are inevitable irrespective of the physical or chemical method used for the synthesis of ZnO nanoparticles. | |

| "Therefore we used preformed heat-treated ZnO nanoparticles for coating a thermolabile substrate, considering the infeasibility of extreme thermal treatment after coating" Ling says. | |

| The researchers found that the ZnO nanoparticles coated paper possesses antibacterial activity against E. coli. The best antibacterial activity could be obtained on illumination with 543 nm, 1000 Lux light, i.e. household fluorescent tube light, for 24 h. Antibacterial activity was also noted in absence of light, but on treatment for 24 h. This supports the fact that antibacterial activity is induced by the hydrogen peroxide (H2O2) generated from ZnO. It is well known that H2O2 is harmful to the cells of living organisms and is the major contributor of antibacterial activity. Thus, the natural tendency of cellulose fibers absorbing moisture and the ZnO nanoparticles generating H2O2 can be taken to the advantage of forming antibacterial wall papers. | |

| The photocatalytic antibacterial wall papers could be used to cover the interiors of residential complexes, hospital walls &nd in particular operation theaters – which would reduce the possibility of infections. This coating approach could possibly be extended to textiles to make suits with antibacterial properties to combat bioterrorism. Bandages coated with ZnO nanoparticles could also help in preventing bacterial infections. | |

| Ling points out that his coating approach can be scaled up for industrial production. | |

| "The possible challenge in this area is the longterm stability of the coated paper used as substrate" he cautions. "There is also a possibility of photocatalytically reduced volatile organic compounds producing stains on the antibacterial wall paper." | |

| Further studies are required to determine the correlation between the size and shape of ZnO nanoparticles coated on paper and their effect on antibacterial activity. | |

| This coating approach can be extended to coat other nanoparticles to suitable substrates to harness their unique properties in specific applications. For example, coating of Al2O3 and SiO2 nanoparticles on a paper surface would provide an economic alternative for thin layer chromatography (TLC) plates in separation science. | |

| Ling's findings were published in a recent paper, titled "Preparation and characterization of ZnO nanoparticles coated paper and its antibacterial activity study", in the September 15, 2006 web edition of Green Chemistry. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.