| Posted: Dec 11, 2006 | |

Algae shells: one example how nanotechnology is trying to copy Mother Nature |

|

| (Nanowerk Spotlight) A large portion of nanoscience and nanomaterial engineering is about trying to copy what has evolved in Nature. Take diatoms; a major group of hard-shelled algae and one of the most common types of phytoplankton. A characteristic feature of diatom cells is that they are encased within a unique cell wall made of silica. Silicate materials are very important in nature and they are closely related to the evolution of living organisms. Diatom walls show a wide diversity in form, some quite beautiful and ornate, but usually consist of two symmetrical sides with a split between them, hence the group name. Diatomaceous earth consists of fossilized remains of diatoms and, as an environmentally friendly material, finds wide use especially in filter applications. It is also used as a mild abrasive, as a mechanical insecticide, as an absorbent for liquids, as an activator in blood clotting studies, and as a component of dynamite. As it is also heat-resistant, it can be used as a thermal insulator. Artificial synthesis of hollow cell walls of diatoms, as generally re-creating the silicate chemistry of Nature by chemical methods, is a key target of nanomaterial science. Researchers in Japan have now reported a method to produce artificial diatomaceous earth-like materials. | |

| Diatoms synthesize their cell walls (also known as frustules or valves) from silicic acid (specifically orthosilicic acid, H4SiO4). The acid is polymerized intra-cellularly, then the wall is extruded to protect the cell. Significantly, relative to the organic cell walls produced by other groups, silica frustules require less energy to synthesize (approximately 8%), potentially a major saving on the overall cell energy budget. | |

| Frustules are intricate species-specific siliceous microstructures and share certain characteristics such as macro-holes ("stria") often arranged regularly (as "areola"). Artificial fabrications of diatom-like silica and analogous materials are a challenging field of material science. For the preparations of artificial diatom-like materials, biological and biomimetic silicification processes have been applied. | |

| On the other hand, as Dr. Masahiro Fujiwara from the National Institute of Advanced Industrial Science and Technology (AIST) in Japan, points out, silica hollow particles are readily prepared by chemical methods. "We developed a simple chemical method that produces silica hollow particles with macroholes in their shell walls, the morphologies of which are analogous to those of diatom earths. The key technology of this preparation was the addition of suitable water-soluble polymers to the inner water phase (IWP) of the water/oil/water (W/O/W) emulsion." | |

|

|

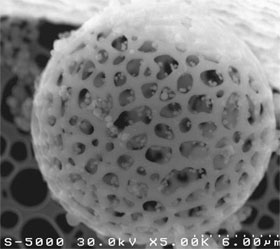

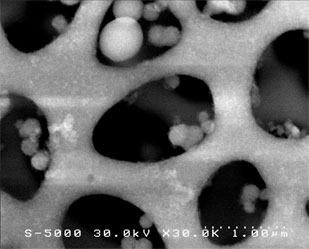

| FE-SEM images of silica hollow particles prepared by W/O/W interfacial reaction method in the presence of sodium polymethacrylate (Image copyright: Dr. Masahiro Fujiwara ) | |

| This result has grown out of research that Fujiwara and his colleagues conducted on interfacial reaction methods for preparing inorganic materials. Previously, they reported the details of the silica microcapsule fabrication by interfacial reaction method using W/O/W emulsion system ("Preparation and Formation Mechanism of Silica Microcapsules (Hollow Sphere) by Water/Oil/Water Interfacial Reaction"). | |

| "The unique character of this method is that the hollow structure is automatically produced in the synthesis" says Fujiwara. "In most other preparation methods of inorganic hollow particles, at first core-shell materials are produced and the core parts (organic components, generally) is removed. The specific feature of our interfacial reaction method enables the direct inclusion of various compounds and does not require additional processes." | |

|

|

| An expected diagram of the formation process of silica hollow particles with macroholes. W/O emulsion with water soluble polymer in inner water phase (IWP) is added to the aqueous solution of NH4HCO3 as outer water phase (OWP), forming W/O/W emulsion. During the silica formation, polymers in IWP pass through the silica matrix to create the macroholes in the shell wall. (Image copyright: Dr. Masahiro Fujiwara ) | |

| And, the preparation period was only several hours – quite short compared to the biological and biomimetic syntheses time of diatom-like materials of Mother Nature. | |

| In their recent research ("Silica hollow spheres with nano-macroholes like diatom earth") the scientists added water soluble polymers such as sodium polymethacrylates in the inner water phase of a sodium silicate solution. | |

| The process provides an entirely artificial method to produce diatomaceous earth-like materials. The macrohole structures depend on the added polymers, so this process is "additive polymer specific" diatomaceous earth synthesis, while real diatomaceous earth materials are "species-specific". | |

| Fujiwara points out that this kind of application can only be achieved through our interfacial reaction method, not in the process via core-shell materials. Although this preparation process is quite simple, the strict control of the shapes of the macroholes still proves to be a challenge. | |

| "In all our experiments, the macroholes were formed but their size and shape always differed" says Fujiwara. "So our process did not quite yet reach the stage of the biomineralization of diatoms." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.