| Posted: Jan 15, 2010 | |

Nanotechnology wool fabric combines multifunctionality with comfort |

|

| (Nanowerk Spotlight) Nanotechnology has brought a new area of finishing applications to the textile industry. Coating the surface of textiles and clothing with nanoparticles has become a common approach for the production of highly active surfaces to have UV blocking, antimicrobial, flame retardant, water repellant or self-cleaning properties. While antimicrobial properties are exerted by nanosilver, UV blocking, self-cleaning and flame-retardant properties are imparted by coatings containing zinc oxide or titanium oxide nanoparticles (see for instance "Nanotechnology finishing in textiles"). Going even further, future smart textiles could actually have fully integrated electronic capabilities that will open a whole new range of applications (see "Nanotechnology e-textiles for biomonitoring and wearable electronics"). | |

| Besides the exciting functionalities that smart textiles will offer its wearer, comfort is also a fundamental and universal need. Clothing comfort not only has an impact on the performances of the people wearing it but ultimately will have a decisive impact on the commercial success or failure of these textiles. | |

| One important aspect of clothing comfort is thermo-physiological comfort. By adjusting the transport of heat and moisture through a fabric, thermo-physiological comfort can keep people comfortable with regard to temperature and moisture. | |

| Some hydrophobic fabrics have deficiencies in this area. Take wool. Wool is one of the best insulating fibers known to man – while at the same time being light and soft. The quality that distinguishes wool fibers is the presence of a fatty, water-repellent outer layer that surrounds each fiber. Therefore, the water absorption and sweat venting properties of wool fiber are not very good, which affects the wearing comfort of wool textiles. The wool hydrophobic surface layer is also a barrier to anticrease finishing, dyeing, and grafting of hydrophilic agents, which is an issue in trying to add smart functionalities to wool fabrics. | |

| Researchers in China have now developed a simple method for fabricating environmentally stable superhydrophilic wool fabrics. They applied silica sols to natural wool fibers to form an ultrathin layer on the surface of the fibers, increasing both the surface roughness and surface energy of the wool fabrics. That way, functionalized fabrics can be obtained by further modification of the surface of the wool fibers with bioactive agents or stimuli-responsive molecules. | |

| "A lot of research has been conducted to improve the hydrophilic properties of wool fabrics, for instance by nonthermal plasma or enzyme treatment of wool fibers," Dong Chen explains to Nanowerk. "However, the hydrophilicity of fabrics treated with nonthermal plasma is not stable during storage in air; and enzyme treatments destroy the scale layer of the wool fiber and lead to irreversible damage to the surface structure of wool fiber." | |

| Chen is a scientists at the Chinese Academy of Sciences (CAS) in Beijing, who is conducting this research while he pursues his PhD degree at The Institute of Textiles and Clothing at Hong Kong Polytechnic University. The project has been led by professors Fangqiong Tang from the Technical Institute of Physics and Chemistry at CAS and Yi Li from The Institute of Textiles and Clothing. | |

| "We adopted a new and simple method, similar to dyeing, for fabricating environmentally stable superhydrophilic wool fabrics" explains Chen. "A transparent and thin layer of silica nanoparticles changes both the surface energy and surface roughness of the wool fibers. Thanks to the silica layer's optical transparence and chemical stability, we obtained functionalized fabrics without changing the color and fabric morphology." | |

|

|

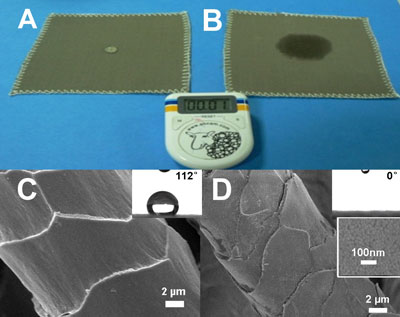

| A and B are photographs of the absorption of water droplets on pristine wool fabric and superhydrophilic wool fabric, respectively; C and D are SEM images of pristine wool fiber and superhydrophilic wool fiber. The inset in C is water contact angle on pristine wool fabric; the insets in D are water contact angle on superhydrophilic wool fabric and a high-magnification SEM image of silica coating layer on superhydrophilic wool fiber. (Image: Dr. CHEN Dong) | |

| The researchers have reported their findings in a recent online issue of Langmuir ("Fabricating Superhydrophilic Wool Fabrics"). | |

| Chen explains the possible mechanism for their relatively simple coating technique: "Coating an ultrathin silica layer onto wool fibers could be dependent on electrostatic interactions between wool fibers and silica sols. Silica sols behave in a similar manner to dye molecules during wet chemical processing. Wool fiber has been known to have free amino and carboxyl groups in the wool backbone as important reactive sites. At pH 3 to 4, a considerable number of internal amino groups are protonated but the carboxyl groups are not substantially protonated until the pH approaches 2, leading to the wool fiber having a positive surface charge. Therefore, acid solution swells wool and will benefit silica sols coating the wool surface." | |

| With fast moisture absorption, diffusion and dry qualities, this breathable wool fabric can keep your skin dry while not clinging to it. Not surprisingly, the researchers see a great potential in applying this novel coated wool fiber to all kinds of sportswear, travel wear, underwear, bedroom fabrics and summer garments for humid climates. | |

| There could also be quite a substantial environmental benefit from these coated wool fibers. Today, the biggest problem of washing wool clothing lies in the shrinkage of the textiles. Consequently, wool garments are often dry cleaned, bringing with it all the environmentally harmful consequences of dry cleaning processes. By developing nanotechnology wool textiles that can absorb a large amount of moisture, dry quickly and are machine-washable without shrinking, household washing machines could largely replace dry cleaners for cleaning wool textiles. | |

| Right now, the stability of the modified wool fibers during washing does not yet meet the expectations of the researchers. "To fully realize the everyday application of functional textiles modified by nanoparticles, the coalescing force between the fiber and the nanoparticles must be enhanced" notes Chen. "In theory, this problem can be resolved by surface modification of the fiber to enhance the chemical bonding between particles and fiber. Right now, this is something we are working on in our lab." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|