| Posted: Feb 03, 2010 | |

Electricity-generating silicone implants to power electronic devices |

|

| (Nanowerk Spotlight) Materials that can produce electricity are at the core of piezoelectric research and the vision of self-powering machines and devices. Nanotechnology researchers are even pursuing nanopiezotronics devices that have the potential of converting biological mechanical energy, acoustic/ultrasonic vibration energy, and biofluid hydraulic energy into electricity, demonstrating a new pathway for self-powering of wireless nanodevices and nanosystems (read: "Nanopiezotronics - a pathway to self-powering nanodevices"). | |

| In addition to miniaturizing piezoelectric devices down to the nanoscale, nanotechnology is also contributing to making next-generation devices more effective. Piezoelectric ceramics for instance generate electrical charge or voltage when they experience stress/strain, and thus are highly efficient at converting mechanical energy into electrical energy. For example, PZT (lead zirconate titanate) is able to convert 80% of the mechanical energy applied to it into electrical energy. However, ceramics are rigid, which greatly limits the applicability of the energy harvesting. | |

| Researchers have now demonstrated that high performance piezoelectric ceramics can be transferred in a scalable process onto rubber or plastic, rendering them flexible without any sacrifice in energy conversion efficiency. | |

| "The motivation of our work mainly was to find a reliable power source for portable electronics and medical devices," Michael McAlpine, an assistant professor of mechanical and aerospace engineering at Princeton University, tells Nanowerk. "Compared to electronic components like memory, cpu, or hard drives, the power source or battery has been the slowest in growth when we talk about mobile computing. On the other hand, the human body is a ideal source of power if we can harness our body motion such as walking, finger typing, or breathing. This would be especially convenient for implantable medical devices such as pacemakers, since surgeries are now required to replace dead batteries. If we could replace those batteries with power directly harvested from the continual motion of the lungs, it could significantly improve the quality of life for patients." | |

|

|

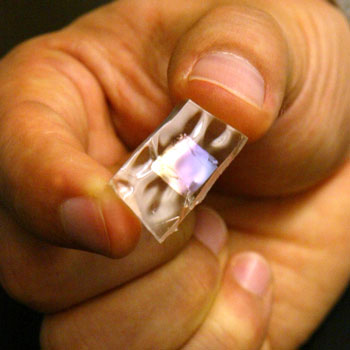

| Photograph of a piece of silicone rubber with PZT ribbons covering the top surface. (Image: Dr. McAlpine, Princeton University) | |

| What McAlpine and his team have fabricated are, in essence, biocompatible power-generating rubber films. By successfully combining the flexibility and biocompatibility of silicone with nanoribbons of high performance inorganic piezoelectric ceramics (PZT), the researchers have created an implantable 'piezo-rubber' that could harness natural body movements such as breathing and walking to power pacemakers, mobile phones and other electronic devices. | |

| The FDA-approved silicone rubber is lightweight and biocompatible, and already used for cosmetic implants and medical devices. | |

| "Power-harvesting devices made of our piezo-rubber could be implanted in the body to perpetually power medical devices, and the body won't reject them" says McAlpine. "Furthermore, the efficiency of energy conversion using these new materials has been shown to be significantly highly than other flexible piezoelectric materials, including the piezoelectric polymer PVDF, and PZT-polymer composites." | |

| A major result from this work is the scalability of the fabrication technique: the team has shown that it can transfer highly crystalline piezoelectric ceramic ribbons in high yields and over large areas onto rubber substrates. | |

| Growth conditions for ceramic crystals are critical for achieving high piezoelectric performance – high temperatures and a carefully chosen growth substrate are required – both incompatible with flexible rubbers or plastics. The way McAlpine's team solved the problem was to first fabricate PZT nanoribbons and then, in a separate process under ambient conditions, print the nanoribbons onto silicone rubber. | |

| McAlpine explains: "First, PZT films were grown on a cleaved magnesium oxide crystal substrate and postannealed to form a perovskite crystal structure. Second, the structure, composition, and piezoelectric response of the films were characterized to ensure optimal performance. Next, the films were patterned into nanothick ribbons and printed onto clear sheets of silicone rubber (PDMS) via dry transfer. Finally, the fundamental piezoelectric properties were characterized on the rubber substrate using a nanoscale characterization method, piezoresponse force microscopy." | |

| According to the researchers, there are a number of key challenges they need to overcome. "In particular" says McAlpine, "future work will help us understand in more detail 1) the mechanics of the piezoelectric on a stretchable platform, 2) the hard inorganic/soft polymeric interface and its longevity under mechano-electrical cycling, and 3) the cointegration of power rectification and regulation electronics on the flexible support." | |

| Another issue is the connectivity between the energy-harvesting piezoelectric device and the device it is supposed to power. | |

| "Specially made smart electrodes are needed to access the electrical energy harnessed by these unique materials" says McAlpine. "We are close to finish a fully functional device and scaling up the performance to a level that can actually power handheld portable electronics. A wide variety of exciting future directions can also be envisioned. For example, in addition to generating electricity when the piezo-rubber is flexed, the opposite is true: the material flexes when electrical current is applied to it. This opens the door to other kinds of applications, such as use for microsurgical devices." | |

| The researchers reported their findings in the January 26, 2010 online issue of Nano Letters ("Piezoelectric Ribbons Printed onto Rubber for Flexible Energy Conversion"). | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|