| Posted: Feb 09, 2010 | |

Spinning kilometers-long, multi-layered carbon nanotube yarns |

|

| (Nanowerk Spotlight) Materials engineers are keen to exploit the outstanding mechanical properties of carbon nanotubes (CNTs) for applications in fibers, composites, fabrics and other larger-scale structures and devices. The ability to fabricate continuous, multifunctional yarns represents an important step in this direction. The development of a continuous, weavable multilayered CNT yarn with superior mechanical, structural, surface, and electrical properties would open the way for a wide range of structural and functional applications, including composites, intelligent fabrics, catalyst supports, and sensors. | |

| So far, researchers have been working on several processes to make macroscale CNT fibers (see for instance: "Spinning carbon nanotube cotton"). | |

| "While the development of a continuous and weavable pure carbon nanotube yarn remains a major challenge in the fabrications, CNT yarns so far obtained from the different processes are monolithic in structure," Ya-Li Li, a professor in the Nanomaterials and PDCs Group at the Key Laboratory of Advanced Ceramics and Machining Technology at Tianjin University in PR China, explains to Nanowerk. "We have now been able to demonstrate the fabrication of a novel continuous yarn of CNTs with a multiple-layer structure by the chemical vapor deposition (CVD) spinning process. The yarn consists of multiple monolayers of CNTs concentrically assembled in seamless tubules along the yarn axis." | |

| According to Li, the fabrication of a CNT yarn by the CVD spinning process relies on the assembly of CNTs in the gas flow by van der Waals interactions. | |

| "The carbon nanotubes assemble in the gas flow when produced in a sufficiently high yield with a high purity such that interaction occurs. Their assembly is, therefore, greatly dependent on the chemistry of the carbon sources." | |

| The assembly of CNTs in the gas flow forms a continuous sock-like CNT integrate, which can be mechanically spun out into a CNT yarn. | |

|

|

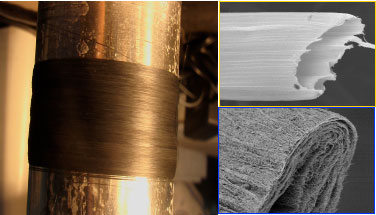

| Continuous carbon nanotube yarns spun directly from the catalytic chemical vapor reaction synthesis (right) and the micro hollow structure of the carbon nanotube yarns (right up) with the multiple layered carbon nanotubes walls (right lower) (images for demonstrations which are not exactly corresponding to the indicated regions) (Image: Dr. Li, Tianjin University) | |

| Li notes that the spinning of multilayered CNT yarns is based on his team's discovery that CNTs can self-assemble into a multilayered CNT 'sock' in the gas flow when a mixture of acetone and ethanol is used as the carbon source. | |

| "The core scientific finding is our discovery that carbon nanotubes can self assemble in the gas flow into multiple geometry of layered structures by controlling the reaction chemistry and synthesis conditions" he says. | |

| The Chinese team from the university's School of Material Science and Engineering reports their findings in a recent issue of Advanced Materials ("Continuous Multilayered Carbon Nanotube Yarns"). | |

| This novel technique makes it possible to fabricate CNT yarns and multiple functional yarns that can be spun over kilometers with controlled CNT structures at atomic levels and micro levels. This is made possible through the innovative spinning methodology including the development of densification method and control of spinning. | |

| The development of a continuous, weavable multilayered CNT yarn which opens the way for a wide range of structural and functional applications, including composites, intelligent fabrics, catalyst supports, and sensors. The yarns can be applied in composites, fabric, structural and functional components just like conventional fibers but – thanks to the carbon nanotubes – with multifunctional properties such as high electrical conductivity and superior mechanical properties. | |

| "Our carbon nanotube yarn can be made either dense or hollow or multiple layered structures to meet specific structural and functional applications" says Li. "The hollow and multiple layer structures allows mass transfer with enhanced contact which can be applied in many fields such as electrochemical system for the development of energy storage materials and in bio-system as tissues, vascular and nerves." | |

| The team is already working on several fronts to further develop their innovation by enlarging the production to provide quantity CNT yarns; fabricating woven fabrics; using the yarn to make composites; and exploring its potential in electrochemical systems and biomaterials including sensors and tissue materials. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|