| Posted: Mar 29, 2007 | |

Suspended nanowire webs for biosensing and catalysis |

|

| (Nanowerk Spotlight) Tremendous progress has been made over the past few years to control the aspects of fabricating simple nanostructures such as wires, tubes, spheres, cubes etc. However, in order to build functional nanodevices, for instance for nanoelectronics or nanobiotechnology, much more complex nanoarchitectures are needed. | |

| Initially, the most common, mostly top-down, fabrication methods used for this purpose have been based on nanolithographic techniques. Unfortunately, these methods are burdened with throughput restrictions and high cost and will be of limited use for commercial mass production of nanostructures. | |

| To overcome the limitations of nanolithography, a lot of attention has been focused on self-organized bottom-up approaches, which bear good prospects for large-scale fabrication of nanostructures with controlled morphology and dimensionality, and controlled synthesis of arrays. | |

| However, the fabrication of complex nanoarchitectures requires sophisticated transfer techniques, which are far from routine, time consuming, and with low reproducibility. | |

| To add to the arsenal of scaleable bottom-up fabrication processes, researchers in Germany have developed a method for the batch fabrication of 3D-nanostructures with tunable surface properties. Resembling suspended nanowire webs, these structures have a high potential for catalytic, sensing, or fluidic applications where a high surface to volume ratio is required. | |

| "We managed the lithography-free processing of a complex three-dimensional nanoarchitecture through a combination of 1) the formation of nanoneedles, 2) the droplet formation out of a thin metal film, and 3) the vapor-liquid-solid (VLS) growth of nanowires" Dr. Volker Cimalla explains to Nanowerk. "Although these self-organization mechanisms are routinely used for fabrication of single building blocks in large quantities and in massively parallel fashion, only a few techniques allow an assembly to organized two- and three-dimensional structures. Here, we combine them for a high-throughput fabrication of a nanoarchitecture with different dimensionality, i.e., a freestanding web (two dimensions) of nanowires (one dimension) suspended from a needle array (three dimensions)." | |

| Cimalla, a research assistant at the Institute of Micro- and Nanotechnologies at the Technical University Ilmenau in Germany, is first author of a recent paper in Applied Physics Letters that describes how to combine the benefits of three self-organization mechanisms to produce nanostructures ("Suspended nanowire web"). | |

| In contrast to previously described 'nanotrees' (see: "Synthesis of branched 'nanotrees' by controlled seeding of multiple branching events"), where on initially grown nanowires new catalysts are deposited to nucleate branching nanowires, the approach by the German scientists realizes a nanoweb with very high distance to the substrate of up to 20 µm, which enables the flow of liquids underneath the structure while keeping its high mechanical stability. | |

| What Cimalla and his collaborators did, in short, was to micropattern silicon wafers with needle structures using a self-masking process, and then use another self-organizing process to grow on these needles a nanowire net with tunable density. | |

| Cimalla points out that the key novelty of their process is the large distance of the nanowire net from the surface due to the high aspect ratio of the needles. Such distances cannot be achieved with common techniques such as branched nanowires. It enables a gas or even a liquid flow beneath the nanowire net. | |

| "These nanowire nets are quasi free-standing, which can be used for both fundamental research of the nanowire properties as well as for the interaction with other objects" says Cimalla. "For example, it enables new studies on the interaction with living cells. Such studies are not possible on flat surfaces, where the cells usually form a protein interlayer." | |

|

|

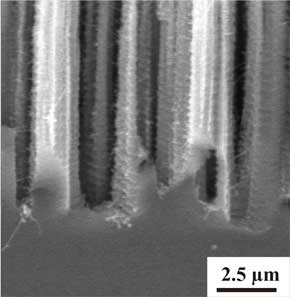

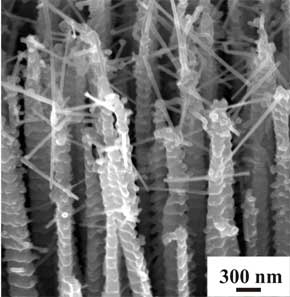

| 45° side view (left) on the bottom and (right) on the top of the silicon needles demonstrating that the wires are growing essentially out from the topmost 100 nm of the silicon needles. (Images: Dr. Cimalla, TU Ilmenau) | |

| The first step in the fabrication process requires the self-organized formation of so-called black silicon, an exotic material that consists of a densely packed silicon needle array (black silicon, discovered by accident in 1999, gets its name from the fact that it efficiently traps light and therefore holds amazing potential for efficiently converting sunlight to electricity, for instance). | |

| The second step uses the established VLS growth of silicon nanowires with gold used as catalyst material. As with step one, this process can also be performed with a variety of different materials. here, on the 3D silicon needle array, the required catalyst (in this case gold) is deposited at grazing incidence with a thickness of about 2?4 nm. The silicon needles are shading each other resulting in a coating of the topmost parts only. | |

| "Our proposed nanoarchitecture has a high potential for catalytic, sensing, or fluidic applications where a high surface to volume ratio is required" says Cimalla. "Increasing the sensor surface can lead to a higher signal level and provide a better signal to noise ratio, whereas microfluidic reactions can be enhanced by providing a large surface covered with catalytic elements. Preliminary experiments have shown that the 3D character of the silicon needle array enables the transport of gases and fluids even beneath the nanowire web." | |

| With ongoing research the researchers in Ilmenau want to use this particular feature for biosensing applications and as a catalytic microreactor. | |

| For the application in bio-MEMS the cells can find a suspended structure for adhesion and still be supplied with extra cellular matrix from underneath. It enables novel biosensing applications such as the direct measurement of the reaction (using the nanowires) of a cell on enzymes etc. | |

| A surface area directly in contact with a fluid flow is the main criterion for efficient catalytic reactions. Cimalla says that preliminary experiments using only the needle array already showed a dramatic increase of the reaction output as a direct result of the increased exposed catalyst surface. | |

| "In contrast to porous catalytic materials, the suspended nanowire web allows much higher fluxes of liquids and gases, which increases its efficiency" he says. "With the further increased effective catalyst surface by nanowires on top of the nanoneedles, where the fluidic resistance is expected to be the smallest, we expect a further improvement." | |

| This novel fabrication process allows for a lot of flexibility: the surface properties can be tuned with different parameter sets available through micro and nano-structuring; the surface can be 100% hydrophobic or 100% hydrophilic; the density of the wires as well as the needles can be adjusted independently; additional materials can be deposited on the nanoweb to widen the application field. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.