| Posted: Aug 24, 2010 | |

Virus-enabled fabrication of stable silicon anodes for lithium-ion batteries |

|

| (Nanowerk Spotlight) Most of today's lithium-ion batteries rely on anodes made from graphite, a form of carbon. There are several candidate electrodes to replace graphite as the anode for lithium-ion batteries. Such electrodes like silicon or tin have very high capacities but suffer from poor efficiency and cyclic stability as they experience large volume change and particle pulverization during repeated cycling. | |

| Silicon-based anodes, for instance, theoretically offer as much as a ten-fold capacity improvement over graphite, but silicon-based anodes have so far not been stable enough for practical use. | |

| Although silicon has been recognized as a favorable anode material – it can hold a larger amount of lithium than carbon – applications of silicon were limited by its inability to sustain physical stress, namely, the fourfold volume increase that silicon undergoes when lithium ions attach themselves to a silicon anode in the process of charging a battery, as well as the shrinkage that occurs when lithium ions are drawn out as it discharges. | |

| Planar silicon thin film anodes suffer from low foot-print capacity, poor rate performance and unsatisfied cycle life but, as Chunsheng Wang explains to Nanowerk, "changing the geometric structure of the current collector from 1D to 3D can overcome these challenges of normal silicon thin film anodes." | |

| Wang, an assistant professor in the Department of Chemical & Biomolecular Engineering at the University of Maryland, notes that silicon nanowires and nanotubes have been used to produce stable silicon anodes. The architecture of these nanowires and tubes allows for a greater level of expansion to accommodate the volume changes that accompany silicon charge and discharge cycles. | |

| In recent work ("Virus-Enabled Silicon Anode for Lithium-Ion Batteries"), Wang, together with two other principal investigators James Culver and Reza Ghodssi) and their teams (with PhD students Konstantions Gerasopoulos in Ghodssi's group and Xilin Chen in Wang's group) have used the macromolecular structure of self-assembled Tobacco mosaic virus (TMV) as templates to fabricate three-dimensional current collectors for high power and high energy density Li-ion batteries. | |

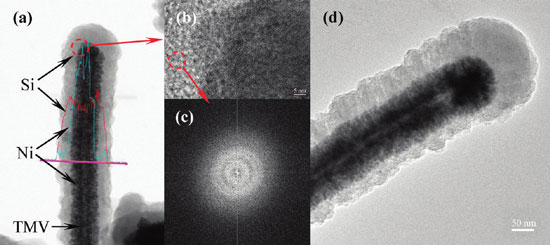

| "The silicon anodes prepared by physical vapor deposition of a silicon layer on a nickel/TMV current collector demonstrated outstanding rate performance, cycling stability and rate capability due to the high electrical conductivity of the inner metal layer within each silicon nanowire and large interface area between silicon and electrolyte compared to conventional silicon thin film anodes" says Wang. "Unlike current methodologies that have utilized biological templates for the synthesis of nanomaterials and relied on powder mixing and ink-casting for the electrode fabrication, our method involves the direct fabrication of a nanostructured silicon electrode." | |

|

|

| TEM image of a vertical TMV1cys/Ni/Si nanowire after 45 min of silicon PVD, including EDS profiles of nickel and silicon. (b) HRTEM image of circled area in (a). (c) FFT image of silicon layer and (d) nonvertical TMV1cys/Ni/Si nanowires after 45 min of silicon PVD. (Reprinted with permission from American Chemical Society) | |

| Testing the abilities of their silicon anodes at room temperature, the researchers found that it produced high capacities (3300 mAh/g), excellent charge–discharge cycling stability (0.20% loss per cycle at 1C), and consistent rate capabilities (46.4% at 4C) between 0 and 1.5 V. | |

| "The biological templated nanocomposite electrode architecture displays a nearly 10-fold increase in capacity over currently available graphite anodes with remarkable cycling stability," says Wang. | |

| The main novelty of work by the University of Maryland team is the direct assembly of the viral molecules on the current collectors as well as the existence of the nickel core inside the silicon shell. This eliminates the need for binders and other conductive additives and increases the efficiency and energy density of the electrode. | |

| The simplicity in fabricating electrodes combined with the bio-renewable nature of the TMV template as well as the potential to integrate this technique into large-scale batch manufacturing processes makes this approach a promising alternative for the realization of next-generation anodes for lithium ion batteries. | |

| "Genetically modifying the TMV enables patterning of the TMV onto metal surfaces as well as enhanced metal coating in electroless plating bath, which can be used to fabricate a 3-D current collector" explains Wang. "Our research team consisting of three groups in battery, biology and device has collaborated on this unique concept since 2008. These electrodes can be scaled for use in both commercial batteries as well as micro and nano power sources, which has been an increasing requirement for autonomous Microsystems." | |

| He also notes that the primary applications his team's work aims towards is the development of power supply for micro-systems. Devices such as wireless distributed sensor networks are gaining significant attention as they can be small in size and deployed in large amounts in various environments for homeland security, environmental and structural monitoring applications, etc. | |

| "These systems require on-chip power supply for autonomous operation and due to their small size the battery has to be small as well while providing the adequate power for proper operation. The self-assembly of the virus combined with its easy integration with batch micro-fabrication that we have demonstrated previously make it a very attractive candidate material for miniature batteries." | |

| The team's research focuses on high power/energy density, long cycle life Li-ion batteries with power ranging from on-chip power supply, electric vehicle power sources, to renewable energy storage. Future research in the field is moving towards the development of technologies to decrease the cost while increasing safety and cycle life at the same time. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|