| Posted: May 13, 2011 | |

What's the environmental footprint of your nanosilver T-shirt? |

|

| (Nanowerk Spotlight) The use of silver nanoparticles in all kinds of consumer goods in daily use, such as personal hygiene articles, cosmetics, food, refrigerators, protective plant sprays and, above all, textiles, has considerable commercial potential and is increasing all the time. Although over 1000 kilograms of nanosilver is already being used each year in environmentally sensitive areas, extremely little is yet known about its effects on the environment. | |

|

|

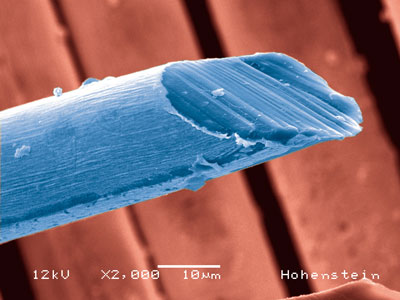

| SEM image of a textile fiber to which silver nanoparticles have been applied. (Source: Hohenstein Institute) | |

| Several manufacturers are incorporating nano-sized particles of silver into, among other things, garments like socks and shirts to kill bacteria that cause odor. But does the silver stay in the socks or T-shirts? And what happens to it if it washes out? Also, what is the climate footprint of producing the required nanosilver? | |

| To answer these questions, a group of researchers from Switzerland, the UK and Germany, led by Stefanie Hellweg, a professor at the Institute of Environmental Engineering at ETH Zurich, have performed a cradle-to-grave life cycle assessment (LCA) to compare nanosilver T-shirts with conventional T-shirts with and without biocidal treatment. For their assessment, the team used conventional T-shirts treated with triclosan, a commonly applied biocide to prevent textiles from emitting undesirable odors. | |

| Reporting their findings in the April 20, 2011 online edition of Environmental Science & Technology ("Prospective Environmental Life Cycle Assessment of Nanosilver T-Shirts"), the team examined two manufacturing processes for nanosilver production and textile incorporation: flame spray pyrolysis (FSP) with melt-spun incorporation of silver nanoparticles and plasma polymerization with silver co-sputtering (PlaSpu). The environmental impacts of conventional, nanosilver, and triclosan T-shirts were compared, with respect to the production, use, and disposal phase. | |

| According to the researchers, "the results show significant differences in environmental burdens between nanoparticle production technologies: The "cradle-to-gate" climate footprint of the production of a nanosilver T-shirt is 2.70 kg of CO2-equiv (FSP) and 7.67 - 166 kg of CO2-equiv (PlaSpu, varying maturity stages). Production of conventional T-shirts with and without the biocide triclosan has emissions of 2.55 kg of CO2-equiv. | |

|

|

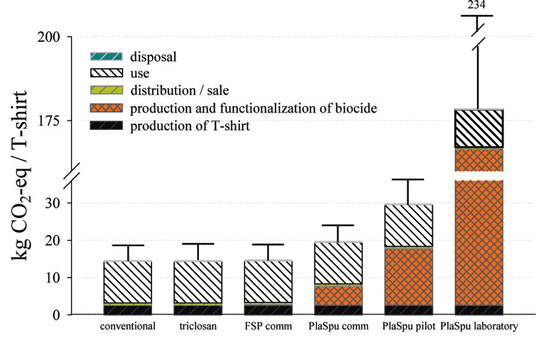

| Cradle-to-grave climate footprint of biocidal T-shirts and a regular T-shirt (100 washings). Error bars show the upper bound of the 95% confidence interval for the results (Monte Carlo analysis of the inventory; Commercialized = Comm.). (Reprinted with permission from American Chemical Society) | |

| The researchers find that FSP and triclosan T-shirts are produced with a much smaller climate footprint than are PlaSpu T-shirts. "Distribution/sale and the disposal phase are of minor importance in the life cycle of the T-shirt and could be further lowered by reducing transport distances, avoiding air transport, and increasing energy efficiency in retail outlets," they write. | |

| The use phase (various cycles of washing and drying the T-shirt) pollutes the environment most if commercial technologies are used (assuming that users would wash their nanosilver T-shirts less). "On the contrary, nanosilver T-shirts produced with the non-commercialized PlaSpu technology have higher climate change impacts during production than in use. Greenhouse gas emissions show high sensitivities to washing load and frequency and lower sensitivities to T-shirt lifetime and washing temperature. Of all tested parameters, a reduction or abandonment of tumbling would reduce the climate footprint the most." | |

| With regard to the toxic impacts of nanosilver versus triclosan, the jury is still out on if and how nanosilver's toxicity impacts the environment. In this study, the researchers believe that toxic releases from washing and disposal in the life cycle of T-shirts appear to be of minor relevance. But: "By contrast, the production phase may be rather significant due to toxic silver emissions at the mining site if high silver quantities are required." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|