| Posted: Aug 08, 2011 | |||

Designer molecules open new manufacturing route for materials scientists |

|||

| (Nanowerk Spotlight) Super-tough materials with exceptional mechanical properties are in critical need for applications under extreme conditions such as jet engines, power turbines, catalytic heat exchangers, military armors, airplanes, and spacecraft. Researchers involved in improving man-made composite materials are trying to understand how some of the amazing high-performance materials found in nature can be copied or even improved upon (see: "Nanotechnology inspired by mussels and seashells"). | |||

| Nature has evolved complex bottom-up methods for fabricating ordered nanostructured materials that often have extraordinary mechanical strength and toughness. One of the best examples is nacre (mother-of-pearl), the pearly internal layer of many mollusc shells. It has evolved through millions of years to a level of optimization currently achieved in very few engineered composites. | |||

| "The main problem in making nanocomposite materials is how the separate components can be interfaced without losing the good properties of each component" Dr. Päivi Laaksonen, a researcher in the Nanobiotechnology group at the VTT Technical Research Centre of Finland, tells Nanowerk. "Often chemical incompatibility prevents efficient transfer of impacts between the materials, which leads to easy fracturing." | |||

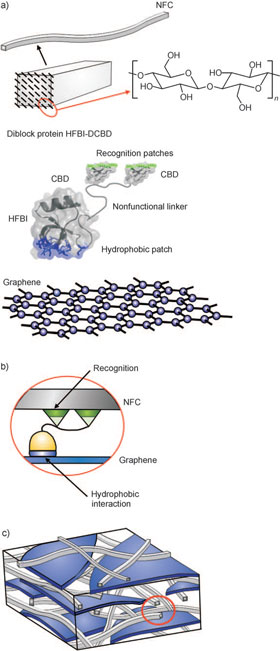

| Laaksonen is first author of a paper in the July 22, 2011 online edition of Angewandte Chemie International Edition ("Genetic Engineering of Biomimetic Nanocomposites: Diblock Proteins, Graphene, and Nanofibrillated Cellulose"), where she and a team of scientist from VTT, Aalto University and the RWTH Aachen describe how they were able to significantly strengthen a nanocellulose paper by gluing flakes of graphene to it. | |||

The team was also able to show that biomolecules that may seem soft and fragile can actually strengthen a composite material by creating cohesion between two materials that differ much from each other. "It appears that a thin layer of biomolecules, only a few nanometers in thickness, can be essential for effective mechanical interlinkage between the components of a composite" says Laaksonen. She explains that, in recent years, there have been different approaches to making biomimetic nanocomposites: "One particularly simple approach has been to self-assemble synthetic polymeric or colloid-like objects, which leads to some success. At the other extreme, designed peptide synthesis allows mimicking of biological nanocomposites in more detail, but the rational design can become challenging." In their recent work, the team suggests a fundamentally new approach where they select high-performance components, relevant for the functionalities pursued, and then genetically engineer biomolecular components that allow tuning of the interconnectivity and properties. The researchers were inspired by recent findings on the structures and functions proteins found in mollusc shells ("An Acidic Matrix Protein, Pif, Is a Key Macromolecule for Nacre Formation"): It was found out that there is a protein that is able to bind both to the mineral platelets and the organic matrix of nacre, although the exact role of this protein in the mechanical properties of nacre has not been verified. "Since we had the possibility to create analogous proteins, we could choose the materials we wanted to combine and simply glued these together with the proteins" says Laaksonen. "This design resulted in our nanocomposite with enhanced mechanical properties." In this work, genetic engineering was employed in creating biomolecules that could glue together materials with different properties. Specifically, a genetically engineered protein showed the ability to connect graphene (stiff) and cellulose (strong) so that it self-assembles at the interfaces. "The idea of interfacing such components comes from biological composites such as nacre and bone where hard and soft materials are effective bound together" explains Laaksonen. "By using genetic engineering we can get rid of the limitation to biological materials and can expand to other materials with more desirable properties, for instance to graphene. We don't need to start from scratch but instead use functionalities that are found in nature and make new combinations from them." |

|||

| This kind of an approach is still quite new in materials science. The VTT team's work shows that using these designer molecules in materials science can actually result in simple manufacturing routes and, what is especially important, in good materials. | |||

| Laaksonen points out that the possibilities to precisely engineer the molecular structures open endless opportunities to design and fine-tune materials properties. Potential applications could include strong biocompatible materials for instance for fabrics, orthopaedics or specialty coatings. | |||

| Creating new materials using genetic engineering is an emerging field. As Laaksonen notes, is the key to achieve significant development through this approach, but keeping up with the development of biotechnological tools is also very important. | |||

| "Considering the societal aspects, biotechnology combined with materials science may provide more sustainable routes towards manufacturing of tailored materials" she concludes. | |||

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|||

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|||