| Posted: Jul 25, 2007 | |

Nanomechanical computers - an answer to today's power-hogging silicon chips? |

|

| (Nanowerk Spotlight) Finding out how much power all the computers in the U.S., not to mention the world, are using seems to be an impossible task. We tried. The latest data from the Department of Energy (DoE) for household computer use is from 2001, for office use, from 1999. This is strange because when you do some back of the envelope calculations you arrive at some pretty staggering numbers. | |

| An estimated 1 billion computers in 2008 will use some 200 billion kWh of electricity (that's roughly what all households in New York City combined use over five years), generating about 127 million tonnes of CO2 in the process. And that's just for desktop and laptop computers, not including peripherals or the billions of chips used in other electronic devices. | |

| Researchers are now proposing to build a fully mechanical computer based on nanoelectromechanical (NEMS) components that would use considerably less energy. Inspired by a classical mechanical computer design from 200 years ago, the main motivation behind constructing such a computer is threefold: (1) mechanical elements are more robust to electromagnetic shocks than current dynamic random access memory (DRAM) based purely on complimentary metal oxide semiconductor (CMOS) technology, (2) the power dissipated can be orders of magnitude below CMOS and (3) the operating temperature of such an NMC can be an order of magnitude above that of conventional CMOS. | |

| Today, such a mechanical computer is only a hypothetical device. However, any effort to reduce the power consumption of computers, and not increase them as happens with every new chip generation, seems like a worthwhile effort. | |

| Here is the power usage data (again, this is a very unscientific back of the envelope calculation): According to market research, computers in use worldwide will top 1 billion in 2008 and 2 billion by 2015. According to DoE figures, the average energy consumption for a PC is 262 kWh per unit per year; for laptops it's 77 kWh. | |

| Let's be conservative and use an average figure of 200 kWh per computer per year. That would give us about 200 billion kWh of electricity a year used by computers. A barrel of oil contains 42 gallons and produces an average 556 kilowatt hours of electrical power. Averaging that with coal and gas, this translates roughly into 0.4 to 1 kg of CO2 (the level of CO2 emission per kWh depends on the type of fossil fuel used - gas-fired power plants: 385g CO2/kWh; coal-fired: 970g CO2/kWh; oil-fired: 740g CO2/kWh; source: Energy Systems Research Unit). Data from the EPA's shows that generating one kW hour of electricity turns into about 1.4 pounds (0.64 kg) of CO2. That means that generating the electricity for using 1 billion computers will release some 128 million tonnes of CO2 (280 billion pounds) into the air. | |

| (By the way, there is a wealth of interesting information in the EPA's massive, 458-pages "Inventory of U.S. Greenhouse Gas Emissions and Sinks". Just a few highlights: The process of generating electricity is the single largest source of CO2 emissions in the United States, representing 39 percent of total CO2 emissions from all CO2 emissions sources across the United States. In 2005, the amount of electricity generated (in kWh) increased by 2.4 percent. However, CO2 emissions increased by 2.8 percent, as a larger share of electricity was generated by coal. Coal is consumed primarily by the electric power sector in the United States, which accounted for 94 percent of total coal consumption for energy purposes in 2005. The amount of electricity generated from renewables decreased by 1.7 percent in 2005.) | |

| On to the real story: Constructing a computational device purely based on nanomechanical elements could be an interesting alternative for micro-processor applications which demand robustness, low power consumption and high-temperature applications. However, given that current operating speeds of nano-electromechanical single electron transistors (NEMSETs) are of the order of 1 GHz, they will not be competitive with standard CMOS in areas where speed is imperative. But there are plenty of applications, ranging from high-temperature automotive applications to toys and domestic appliances where these robust mechanical computers could find use – and reduce power consumption as a beneficial side effect. | |

| And, of course, the military is interested in such a nanomechanical computer (NMC) because unlike silicon chips, nano mechanical devices are not susceptible to electromagnetic pulses, which could be used by an enemy to knock out computing systems. | |

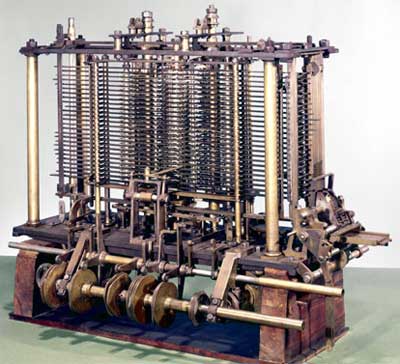

| The idea of a mechanical computer goes back to Charles Babbage's difference engine (actually, you could argue it goes back some 2,000 years to the Antikythera mechanism, but that might be a bit of a stretch). In recognition of the high error rate in the calculation of mathematical tables, Babbage wanted to find a method by which they could be calculated mechanically, removing human sources of error. The first difference engine needed around 25,000 parts of a combined weight of 13,600 kg standing 8 ft (2.4 m) high. He later designed an improved version, "Difference Engine No. 2". This was not constructed at the time, but was built using his plans in 1989-1991, to 19th century tolerances, and performed its first calculation at the London Science Museum returning results to 31 digits, far more than the average modern pocket calculator. | |

|

Babbage's Analytical Engine, 1834-1871. This was the first fully-automatic calculating machine. (Image: London Science Museum) |

| Dr. Robert H. Blick, Lynn H. Matthias Professor II in Engineering in the Department of Electrical & Computer Engineering at the University of Wisconsin-Madison, and his colleagues were inspired by Babbage's ideas but rather than constructing a 14-ton monster they are now operating at the nanoscale. In a recent paper ("A nanomechanical computer?exploring new avenues of computing") they introduce the idea of a nanomechanical computer. | |

| The authors say that, based on ultra-hard materials such as diamond, which can be doped and processed straightforwardly, such an NMC can withstand extreme temperatures." The operating temperature can be as high as 500°C. This is of great interest for space-born operation and other harsh environments or when the available power is limited. We estimate that operation with externally applied dc voltages is feasible. These voltages can be generated either by a battery or by a manually actuated battery charger." | |

| Unlike modern electronics, where the flow of charge around circuits is used to perform binary operations, the NMC would use the push and pull of each tiny part to carry out calculations; in principle pretty much like Babbage's difference engine. Blick and his colleagues are currently building the first transistors needed for the computer. "We have demonstrated that a single element of these transistors work," says Blick. He is also confident that working circuits could be built. | |

|

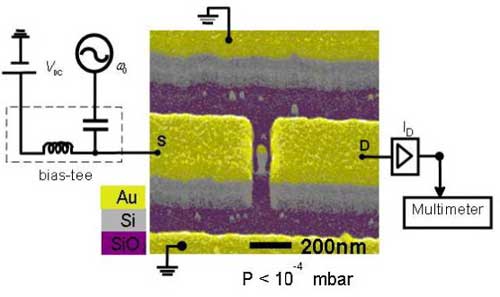

Typical NEMSET: using FE the current can be increased by an order of magnitude. The bias-tee on the left hand side allows application of an ac signal and dc voltage bias. The recorded current depends on the nanomechanical pillar in the center. The gate electrodes are grounded in this particular experiment. (Image: IOP Publishing Ltd and Deutsche Physikalische Gesellschaft) |

| While such a NMC is years into the future, a practical use may lie in hybrid chips, where NMC can be realized in silicon substrates that naturally allow for combining with traditional CMOS circuitry. Such devices would be more robust and consume less power than today's power-hogging chips. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.