| Posted: Jan 30, 2012 | |

Graphene sets new record as the most efficient filler for thermal interface materials |

|

| (Nanowerk Spotlight) Due to rapidly increasing power densities in electronics, managing the resulting heat has become one of the most critical issues in computer and semiconductor design (see our previous Nanowerk Spotlight: "Nanotechnology to the rescue of overheating computer chips"). As a matter of fact, heat dissipation has become a fundamental problem of electronic transport at the nanoscale. Better heat removal is important not only for electronics but also for energy generation, e.g. for preventing overheating of solar cells. | |

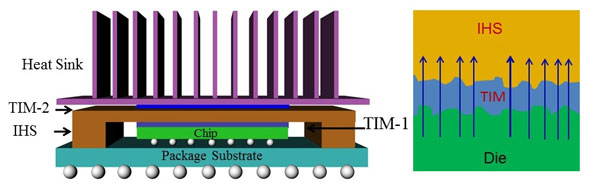

| Thermal interface materials (TIMs) are essential ingredients of thermal management. TIMs are applied between the heat source, e.g. computer chips, and heat sinks and their function is to fill the voids and grooves created by imperfect surface finish of mating surfaces (see Figure 1). Conventional TIMs filled with thermally conductive particles require high volume fractions of filler particles (f∼50%) to achieve the thermal conductivity of the composite in the range of approximately 1-5 W/mK at room temperature. | |

|

|

| Figure 1: Schematic of a computer chip attached to the integrated heat spreader (IHS) with the help of the first TIM layer (left panel). The IHS is attached to the heat sink with the help of the second TIM layer. Interface between the die and HIS filled with TIM for improved heat transfer (right panel). (Image: K.M.F. Shahil and A.A. Balandin, UC Riverside) | |

| "The increase of the thermal conductivity of commercial TIMs from the present 5 W/mK to 25 W/mK would revolutionize not only electronics but also energy generation, for examples solar cells," Alexander Balandin, a professor of electrical engineering at the UC Riverside Bourns College of Engineering, tells Nanowerk. "Many groups are trying to experiment with different fillers that go to the base material to create composites with high thermal conductivity. To be used as TIMs, these composites have to meet a number of other requirements such as proper viscosity and low cost." | |

| As reported in the January 3, 2012, online edition of Nano Letters ("Graphene-Multilayer Graphene Nanocomposites as Highly Efficient Thermal Interface Materials"), Balandin's Nano-Device Laboratory research group achieved a record enhancement of the thermal conductivity of TIMs by addition of an optimized mixture of graphene and multilayer graphene. | |

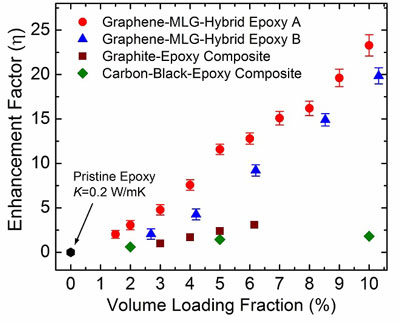

| The thermal conductivity of the epoxy matrix material was increased by an impressive factor of 23 at the 10 volume % of graphene loading (see Figure 2). The epoxy-graphene composite preserved all the properties required for industrial TIM applications. | |

|

|

| Figure 2: Measured thermal conductivity enhancement factor as a fraction of the graphene/few-layer-graphene filler volume loading fraction. Note an extremely large enhancement of ∼2300% at f=10 vol. % for the optimum nanocomposite. (Image: K.M.F. Shahil and A.A. Balandin, UC Riverside) | |

| "The important thing for practical applications is that we prepared our own graphene/few-layer-graphene solution using an inexpensive liquid-phase-exfoliation technique" says Balandin. "This is a high-yield technique which can be scaled up for industrial production of TIMs. The equipment we used was not very complicated." | |

| He adds that the team's results might also be interesting for physicists to consider: it has been established that the presence of a certain fraction of the single and bilayer graphene simultaneously with the thicker graphitic multilayers was essential for the thermal conductivity enhancement. | |

| "It is likely that the excellent performance of graphene compared to carbon nanotubes is related to the smaller Kapitza resistance (named after the Russian physicist P.L. Kapitza, a Nobel Prize Laureate in Physics) between graphene and the matrix material – graphene just couples to the matrix better," adds Balandin. | |

| The results of Balandin's group advances the field by demonstrating that graphene and few-layer graphene flakes can be more efficient filler materials for increasing the thermal conductivity of TIMs than conventionally used fillers such as alumina nanoparticles. The graphene and few-layer graphene used by the team were obtained by a scalable technique with the use of few chemicals. | |

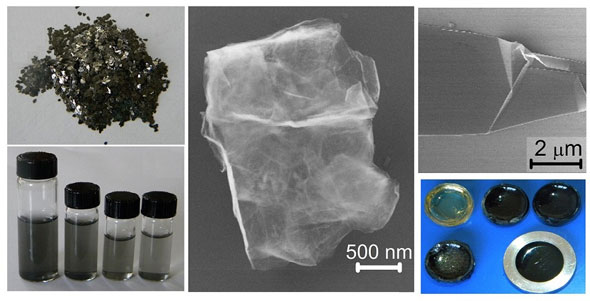

| The new graphene-based fillers are different from previously tried carbon nanotubes or graphitic nanoplatelets, which are thicker graphitic particles with nanoscale dimensions. Earlier attempts of utilizing highly thermally conductive nanomaterials such as carbon nanotubes as fillers in TIMs have not led to practical applications due to weak thermal coupling of the carbon nanotubes to the matrix (i.e. base) materials and prohibitive cost. The Balandin group breakthrough became possible owing to better coupling of graphene to the base epoxy material (see Figure 3). | |

|

|

| Figure 3: Illustration of the synthesis and characterization of the graphene - polymer nanocomposite TIM. Optical image of the graphite source material and graphene solution (left panel); scanning electron microscopy of the few-layer graphene flake (center panel); image of the long graphene layer and different types of TIMs prepared with graphene (right panel) (Image: K.M.F. Shahil and A.A. Balandin, UC Riverside) | |

| "I have been studying thermal properties of nanostructures – including extremely thin films and nanowires – since 1997" Balandin explains the history of this research. "My motivation was to use nanoscale effects for controlling the propagation of phonons, which are the heat carriers in many materials. In 2005, during my sabbatical at Cambridge University, U.K., I became interested in the epoxy composites with carbon nanotubes. The carbon nanotubes were added with the purpose of increasing thermal conductivity of the resulting composites. I shared my thoughts on how to improve such composites for the use as thermal interface materials with some of my colleagues at UC Riverside. However, carbon nanotubes did not work well as thermal fillers. In 2008, we discovered that graphene has outstanding intrinsic thermal conductivity and started to work on the use of graphene as the TIM filler. The next major step came when we learn about the liquid-phase exfoliated technique and started to prepare it ourselves in sufficient quantities. The extra practical motivation for this work came from my service in the expert-panel on carbon-based TIMs at the ITherm conference in Las Vegas in 2010." | |

| In their recent work, Balandin's team demonstrated a major improvement in the thermal conductivity of the epoxy-based composite and one industrial grease-type TIM. For the commercial grease, used by the electronic industry as actual TIM, they were able to increase the thermal conductivity from 5.8 W/mK to 14 W/mK with an addition of only 2% of graphene. The researchers are now planning to work with industry engineers to develop the next generation of TIMs, which would be based on graphene and meet specific requirements of different applications. | |

| "Another practical result of the thermal research done in my laboratory is that none of my students graduating with a PhD degree has had any problems with their job search," says Balandin. "Many of them are now with Intel Corporation, Texas Instruments and other technology leaders. Farhan Shahil, who was working on this graphene TIM project has already accepted Intel's offer and will have his PhD defense very soon." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|