| Posted: Mar 09, 2012 | |

Nanobrick walls make excellent gas barriers and flame retardants |

|

| (Nanowerk Spotlight) Polyurethane (PU) foam is an extremely versatile material that commonly is used in bedding, upholstery and building insulation. However, PU foam is very flammable, often resulting in dripping of melted material that enhances flame spread through the formation of a pool fire under the burning object. Brominated flame retardant compounds (e.g. pentabromodiphenyl ether) have been used to reduce foam flammability but there is growing evidence that these chemicals are toxic to the environment and living organisms. | |

| Replacing brominated flame retardants in polymer formulations with safer and more environmentally-friendly alternatives has also sparked the interest of nanoscientists. For instance, they have found that carbon nanotubes and clay can improve the flame retardancy of plastics. Their flame retarding mechanisms are different and their effect for improving the flame retardancy is limited when they are used alone. However, when they are used together, a significant synergism happens (see our Nanowerk Spotlight: "Flame-retardant materials with more nanotechnology and less toxic chemicals"). | |

| Another, more recent effort to create an environmentally-friendly flame retardant system involves the layer-by-layer assembly of thin films using materials obtained from completely renewable sources. | |

| "Our goal was to develop a truly 'green' film with flame-retardant and oxygen-barrier characteristics" Jaime C. Grunlan, Associate Professor and Gulf Oil/Thomas A. Dietz Development Professor in the Department of Mechanical Engineering at Texas A&M University, tells Nanowerk. "To our knowledge, this is the first study of a flame suppressing thin film consisting of completely renewable materials." | |

| The general topic of safe flame retardant technologies is very timely, with many of the commonly used halogenated materials being restricted around the world. With legislation banning brominated compounds, there is a significant need for new anti flammable technologies that are not harmful to environment and do not degrade other important properties of a given object. | |

| "Our coating provides improvement to the flame retardancy of the foam but it does not alter its physical properties," says Grunlan. "This is also the first demonstration of a high gas barrier thin film made from these same materials." | |

| Grunlan and his team reported their findings in the February 16, 2012 online edition of Applied Materials & Interfaces ("Clay–Chitosan Nanobrick Walls: Completely Renewable Gas Barrier and Flame-Retardant Nanocoatings"), first-authored by Galina Laufer, a PhD student in Grunlan's Polymer NanoComposites Group. | |

| For this study, foams were hand-dipped into solutions to deposit the flame retardant coating. Ten bilayers of chitosan, which is extracted from the shells of crustaceans, as the cationic layer, and montmorillonite clay platelets as the anionic layer, were deposited on flexible PU foam. | |

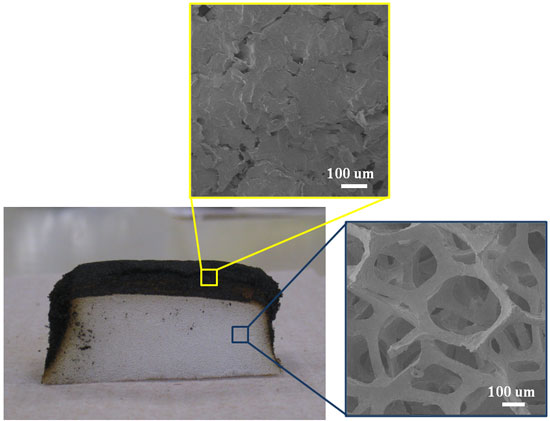

| This nanocoating completely stops the melting of a foam and after being exposed to the direct flame from a butane torch for 10 seconds, only the outermost surface was charred for coated foam. When cut open, undamaged white flexible foam was revealed under a black char layer. In addition to imparting anti flammable behavior to foam, a 30 bilayer chitosan-clay nanocoating (~100 nm thick) reduces the oxygen permeability of a 0.5 mm thick polylactic acid (PLA) film by four orders of magnitude. | |

|

|

| SEM images of locations within a flexible, open-cell polyurethane foam, coated with 10 bilayers of clay and chitosan (at pH 6), following exposure to direct flame from a butane torch for 10 seconds. The photo on the left shows that only the exterior of the foam is charred, while the interior is completely undamaged. Without this 10-bilayer chitosan-clay coating, that is only 32 nm thick, that same torch exposure causes the same foam to melt into a flaming puddle and ultimately vanish as it gives off toxic gas. If the foam were in a chair, it would have melt dripped onto the floor and started the rug on fire and ultimately this is how an entire house burns down. (Images: Jaime C. Grunlan, Texas A&M University) | |

| As Grunlan points out, in this case, you have a high barrier plastic film that is fully renewable and/or biodegradable, which is of great interest in food and other types of packaging. | |

| "Specifically for foam, the potential applications can vary from bedding to building insulation" he says. "There are virtually no limits because this technology could be deposited on a variety of substrate chemistries and geometries – fabric, insulating tiles, etc. With regard to gas barrier, these coating could be deposited onto PET to produce soda bottles with greater shelf life and as a foil replacement for potato chip bags." | |

| "For barrier" he continues, "PLA film is very desirable for its biodegradability, but it has very poor oxygen barrier that limits its use in many packaging applications. Just 15 bilayers of chitosan-clay (~49 nm thick) impart 0.5mm PLA film with a barrier better than 0.175 mm PET,i.e., the material used for soda bottles and many types of food packaging." | |

| For large scale applications, the fabrication process currently used by the Texas A&M team would be very time consuming and unrealistic, so other deposition methods are being investigated. One of the methods is spraying depositing solutions onto a substrate using spray guns. This process would be fast, easy and can be applied to a substrate of any size. | |

| One of the researchers' next steps is to develop flame retardant coating that is durable and is able to withstand multiple laundry cycles without losing its anti flammable characteristics. | |

| "For barrier, we are continually working to achieve higher barrier with fewer layers, which will make this even more attractive for commercial scale-up," says Grunlan. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|