| Posted: Jul 17, 2012 | |

Realization of dense carbon nanotube-concentrated ceramics with unprecedented properties |

|

| (Nanowerk Spotlight) In recent years, there has been growing interest – and progress – in the design and fabrication of carbon nanotube (CNT) macrostructures for effective utilization of their remarkable properties at the macroscale. Realization of such highly concentrated CNT macrostructures, however, in a stiff/elastic environment able to impose compression on individual CNTs and CNT/CNT junctions, could dramatically improve their network connectivity, transport property, and durability, and perhaps lead to novel organic/inorganic hybrids with unprecedented multifunctional properties. Neither the concept nor its practical realization and resultant properties have been reported yet, as they face a tremendous challenge: extremely facile re-agglomeration of individual CNTs in high concentrations (upon environmental changes), which effectively prevents compression of individual CNTs trapped inside their cage-like agglomerates and that forms a porous, fragile hybrid. | |

| In a new study, researchers from National Institute for Materials Science (NIMS, Japan) and Tohoku University have effectively addressed this challenge and proposed a new concept – a highly concentrated, 3D macrostructure of individual multiwalled CNTs (MWCNTs) in a ceramic environment – that dramatically improves not only the transport property and network connectivity of the MWCNT 3D macrostructure but also the strain tolerance of the ceramic material. | |

| Mehdi Estili, a NIMS postdoctoral researcher, is the first/corresponding author of the recent paper in Advanced Materials ("Highly Concentrated 3D Macrostructure of Individual Carbon Nanotubes in a Ceramic Environment") where he, together with Professor Yoshio Sakka, director of the NIMS Materials Processing Unit and prof. Akira Kawasaki from Tohoku University, present their novel concept, scalable preparation method, and fascinating unprecedented properties of their “MWCNT-concentrated ceramic”. | |

|

|

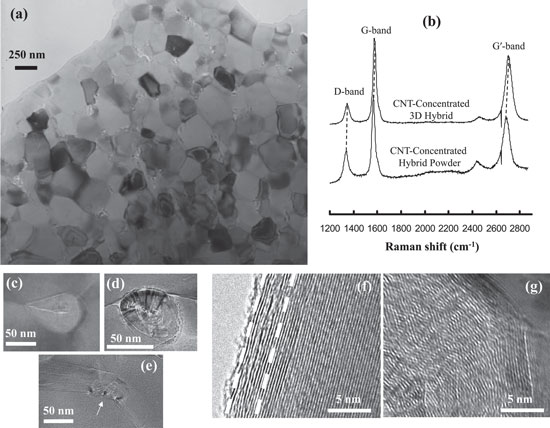

| TEM images (a,c-g) and Raman spectra (b) of MWCNTs in hybrid powder and fully dense 3D hybrid. a) TEM image showing the presence of randomly oriented, uniformly dispersed, individual MWCNTs on the boundaries of a poreless, structurally uniform, nanostructured, polycrystalline ceramic environment. c–e) TEM images of individual, strained MWCNTs in the ceramic environment (radial and longitudinal). f,g) HRTEM images of individual MWCNTs in powder (f) and in the fully dense hybrid (g). The dashed lines in (f) indicate the few-nanometer-thick region of permanent surface irregularities formed during the functionalization process, while the larger, inner region consists of highly straight and parallel carbon walls, which then become irregular after shrinkage (g). (Reprinted with permission from Wiley-VCH Verlag) | |

| In his opinion, MWCNTs, compared to the very expensive single-walled CNTs, are a far better candidate for the practical realization of this novel concept, as they contain numerous, concentrically nested, intact/high-quality carbon walls, which could be effectively exploited in conducting electricity or load bearing ("Engineering Strong Intergraphene Shear Resistance in Multi-walled Carbon Nanotubes and Dramatic Tensile Improvements"). | |

| "MWCNT-concentrated ceramics are attractive for various fields such as thermoelectric power generation, functionally graded materials, biomaterials, strain-tolerant and thermal-shock-resistant multifunctional ceramics, the design and manufacture of complex metal-ceramic engineering components, static-charge dissipation devices, electric-discharge manufacturing, and many more," Estili tells Nanowerk. | |

| The team obtained the most concentrated (20 vol%) 3D macrostructure of individual MWCNTs ever realized in a ceramic environment, by using a scalable, aqueous colloidal method followed by a rapid pressure and pulsed DC-current-assisted densification process (commonly known as pulsed electric current assisted sintering (ECAS) or spark plasma sintering (SPS)), and described the transport property and functionality of their MWCNT 3D macrostructure. | |

| "Our MWCNT 3D macrostructure, which is intimately embedded in an alumina ceramic environment, showed an exceptional network connectivity and DC-conductivity of nearly 5000 S m-1, which approaches those of single MWCNT nanostructures and hot-pressed, aligned, or highly compacted (~90% dense) MWCNT 3D macrostructures, and is dramatically higher than those of porous 3D MWCNT macrostructures (free-standing or embedded (as in composites)) and even some 2D MWCNT macrostructures reported in the literature” says Estili. | |

| He explains that this remarkable transport property originates from the internal strain formed by ceramic crystals, which results in the connection and exploitation of numerous, generally-useless inner walls of individual MWCNTs serving as new conduction pathways and also the formation of intimate nanotube/nanotube local contacts. | |

| "Furthermore, this CNT-concentrated 3D macrostructure dramatically enhances the strain-to-failure of the ceramic material without deteriorating its strength and toughness," he adds. | |

| For their work, the researchers used a modified version of an aqueous colloidal approach that Estili and Kawasaki developed back in 2007 ("An approach to mass-producing individually alumina-decorated multi-walled carbon nanotubes with optimized and controlled compositions"). | |

| "The purpose of our modification is to prevent the facile re-agglomeration phenomenon by sandwiching the entire MWCNT nanostructures with ceramic nanoparticles before the water is removed," explains Estili. "The way in which we realized a uniform dispersion of the record-breaking 20.0 vol% of individual nanotubes within the alumina ceramic was the prolongation of the sonication of the aqueous mixture until the MWCNT suspension was entirely transferred to the ceramic one." He points out that this strategy effectively prevents the attraction and immobilization of a large number of ceramic particles by MWCNTs added at the beginning of mixing, and therefore more ceramic particles become available to sandwich the rest of the MWCNTs to be added; that is, more MWCNTs can then be incorporated within the ceramic powder without re-agglomeration. | |

| "Our study could, in principle, stimulate multidisciplinary applied research on MWCNT-concentrated ceramics, which are attractive for various functional and structural applications, and that open the doors for massive and sustainable utilization of low-cost MWCNT nanostructures," concludes Estili. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|