| Posted: Aug 15, 2012 | |

Electronic sensing with your fingertips |

|

| (Nanowerk Spotlight) Recent advances in materials, fabrication strategies and device designs for flexible and stretchable electronics and sensors make it possible to envision a not-too-distant future where ultra-thin, flexible circuits based on inorganic semiconductors can be wrapped and attached to any imaginable surface, including body parts and even internal organs (see our previous Nanowerk Spotlight "Curvilinear electronics that fit golf balls and body parts"). Robotic technologies will also benefit as it becomes possible to fabricate 'electronic skin' that, for instance, could allow surgical robots to interact, in a soft contacting mode, with their surroundings through touch. | |

| In their latest work, Professor John A. Rogers and his research group at the University of Illinois at Urbana-Champaign have demonstrated that they can integrate high-quality silicon and other semiconductor devices on thin, stretchable sheets, to make systems that not only match the mechanics of the epidermis, but which take the full three dimensional shapes of the fingertip – and, by extension, other appendages or even internal organs, such as the heart. | |

| The team reported their findings in the August 10, 2012, online edition of Nanotechnology ("Silicon nanomembranes for fingertip electronics"). In it, they establish procedures and design rules for electronics and sensors that can be mounted conformably onto the fingers – or any other body parts, for that matter. | |

| In previous work, about a year ago, Rogers and his team demonstrated thin, stretchable 'epidermal' sheets of electronics, suitable for integration on regions of the skin, such as the forearm, that are relatively flat (see their paper in Science: "Epidermal Electronics"). | |

|

|

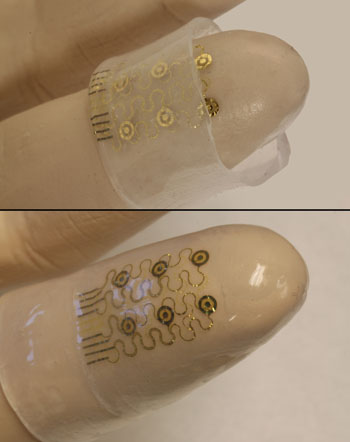

| Top: Turning the tube inside out relocates the array on the inner surface of the finger-tube, shown here at the midway point of this flipping process. Bottom: Multiplexed array of electrotactile stimulators in a stretchable, mesh geometry on the inner surface of an elastomeric finger-tube. (Images: Rogers Group, University of Illinois at Urbana-Champaign) | |

| "We became interested in figuring out ways to do similar classes of devices, but with full, 3D shapes, matched precisely to the body," Rogers tells Nanowerk. "Fingertip was a good starting point to demonstrate the ideas." | |

| Instrumented gloves have been demonstrated in the past, although not with fully functional, flexible silicon electronics. Also, the glove substrates in those cases are thick leather or cloth, much different than the ultrathin, stretchable silicone membranes that Rogers' team uses. | |

| To fabricate their 'fingertip electronics', the researchers first formed an array of interconnected sensors and electronics on a silicon wafer in an open mesh geometry. They then lifted this device structure onto the surface of a PDMS (polydimethylsiloxane) slab via transfer printing. The back side of the mesh and the supporting PDMS stamp are coated with a thin layer of silicon dioxide and then pressed onto a thin elastomeric sheet. Removal of the PDMS completes the transfer. | |

| By choosing an elastomeric closed-tube structure, specially formed to match the shapes of fingertips, the team demonstrated their technique with a set of multifunctional fingertip devices that include electrotactile electrode arrays multiplexed with silicon nanomembrane diodes, strain sensors based on silicon nanomembrane gauges, and tactile sensor arrays that use capacitors with low modulus, elastomeric dielectrics. | |

| "A key step in the manufacturing is a process by which we 'flip inside out' the finger-shaped membrane, to move the electronics from the outer surface, where we do the integration, to the inner surface where it can contact the skin," explains Rogers. | |

| Apart from the demonstrated sensor arrays, such fingertip devices could also be fitted with sensors for measuring motion and temperature, with small-scale heaters as actuators for ablation and other related operations. | |

| Overall, this fabrication technique solves the problem of integrating a hard, brittle material like silicon, with a soft, stretchable membrane of silicone, in a way that affords overall stretchable mechanics but avoids fracture in the silicon. | |

| "We use nanomembranes of silicon, structured into narrow,'serpentine' ribbons, such that buckling physics can accommodate in-plane strains without reaching fracture thresholds in the silicon," says Rogers. | |

| The team believes that these devices can, in a general sense, increase the sensitivity of existing forms of perception through the skin of the fingertip, and also bring new types of sensing function. According to Rogers, an initial application area might be in advanced surgical gloves that improve the sense of touch, and also allow for electrophysiologial measurements, blood pressure assessments, and even potentially therapeutic function (e.g. RF ablation to eliminate aberrant tissues). | |

| The researchers are now working on 3D integration of similar classes of technologies, but with expanded advanced functionality, to organs such as the heart, where the device can measure electrical activity and also stimulate as an advanced class of pacemaker with feedback control. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|