| Posted: Aug 20, 2012 | |

Liquid metal marbles as a novel platform for developing soft electronics |

|

| (Nanowerk Spotlight) Chemical and analytical processes using channel-based microfluidics have many advantages, such as the reduced use of chemical reagents and solvents; precisely controlled reaction condition; much shortened reaction time; and the ability to integrate into a digital device. However, it is difficult with channel microfluidics to handle just a single droplet. | |

| In contrast with the microchannel-based fluidics, the manipulation of discrete droplets without using channels is a new field. Here, a liquid droplet is not confined to a closed channel and there is no risk of it being adsorbed on a channel wall. A 'liquid marble' – a non-stick drop of liquid (such as water and organic solvents) coated with micro- or nanoparticles – is a novel kind of microfluidic device, one that is especially useful for handling single liquid droplet (read more in our previous Nanowerk Spotlight: "Magnetic liquid marbles as an alternative to microchannel-based fluidics"). | |

| "Plenty of applications have been shown for liquid marbles so far, including sensing, movements on demand and micro-capsules for manipulating drugs and chemicals," Kourosh Kalantar-zadeh, an Associate Professor at RMIT University who leads the Micro/nanoelectronics and Sensors Group, tells Nanowerk. "However, these systems have many limitations: the particles used for coating of conventional liquid marbles are generally limited to hydrophobic materials; for allowing electronic current within the liquid marbles, ions are required that can disrupt the structure; there are limitations about the type and size of the particles to be used and many more." | |

| Given these limitations, Kalantar-zadeh and his team, led by Prof. Arnan Mitchell, came up with the idea of developing 'liquid metal marbles' when they wanted to develop a flexible conductive system for electronic and electromagnetic units (for instance a flexible transistors and antennae). | |

|

|

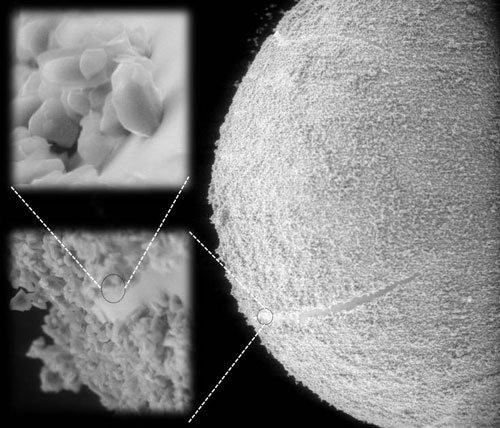

| SEM images of a liquid metal marble: galinstan droplet encapsulated in a coating of 80 nm WO3 nanoparticles. (Images: Vijay Sivan, RMIT University) | |

| "We initially used liquid metal droplets but faced some problems for their implementations," says Kalantar-zadeh. "Non sticky liquid metals such as mercury are toxic. Other alternative liquid metals, such as galinstan – an alloy of tin, gallium and indium – are much safer to used but have a high tendency to stick to everything." | |

| Liquid metals possess unique properties such as high density, high surface tension, and extremely low vapor pressure, allowing them to operate as liquids under vacuum conditions and at high temperatures. Especially important for applications in soft and stretchable electronics, liquid metals offer the highest conductivity of any liquids, with orders of magnitude less resistive loss than ionic fluids. | |

| Unfortunately, liquid metals are highly corrosive and they tend to adhere to their environment, i.e. they are very sticky. To solve these problems, the RMIT team applied a similar concept as liquid marbles to liquid metals and covered the surface of these liquid metal droplets with selected coatings. They became non-sticky. | |

| Reporting their work in the August 7, 2012, online edition of Advanced Functional Materials ("Liquid Metal Marbles"), first authored by Vijay Sivan, the researchers describe a simple approach to fabricating liquid metal marbles that represents a significant platform for the advancement of research into soft electronics. | |

| Kalantar-zadeh points out that the fabrication process is not limited to hydrophobic powder coatings: "A wide range of materials from insulating (various polymers, SiO2,...) , to semiconducting (ZnO, WO3, Si, ...) and on the other extreme highly conducting (metallic single wall carbon nanotubes) can be used. This means that we have created a system with a highly conductive core and a coating of highly controlled electronic properties." | |

| Video of a dropping liquid metal marble. The surface of the marble has been covered with inorganic nanoparticles. | |

| The physical and chemical properties of the liquid metal marbles are significantly different from liquid marbles. They can endure much stronger impacts, they can operate like semiconducting-conducting systems, they can tolerate high temperatures, and they are compatible with micro- and nanofluidic systems. | |

| These extraordinary physical properties of liquid metal marbles and their endurance allow them to tolerate high impacts without disintegration. They are like flexible ball bearings that can be used in many industries. | |

| The researchers also point to the idea of liquid electronics based on liquid metal marbles. The liquid metal drops can not only move and form makeshift electronic devices,they are also able to produce strong plasmonic fields around them. For sensing applications, they are a safe alternative to mercury-based heavy metal ion sensors that offer high sensitivity and selectivity. | |

| To demonstrate this last point, the team fabricated a highly sensitive and selective heavy metal ion sensor based on a galinstan droplet covered in a dense multi-layer WO3 coating. | |

| The research team believes that the potential of liquid metal marbles is extraordinary. "There are many other possible applications that can be considered, especially with the extraordinary capabilities of nanopowder coatings that will lead to liquid metal marble systems with enhanced capabilities" says Kalantar-zadeh. "Our preliminary demonstrations certainly illustrate promise of what this new approach to the use of liquid metals as liquid metal marbles can offer for future scientific research and technological applications." | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|